በርቷል 15ሀ November 2024, a customer was looking for a supplier of a turnkey production line for the manufacture of charcoal briquette made from different materials. “I was the CEO of the company PROVALOA which provides technical solutions to Tanzania companies in the field of food and energy processing. So please send us the quote of a complete line to produce 1000 kg/h.” For this, we send him a YS-140 charcoal extruding line. The following are the specific details of communication in this case:

ንድፍ ምንድነው? 1000 kg/h charcoal briquette making in Tanzania?

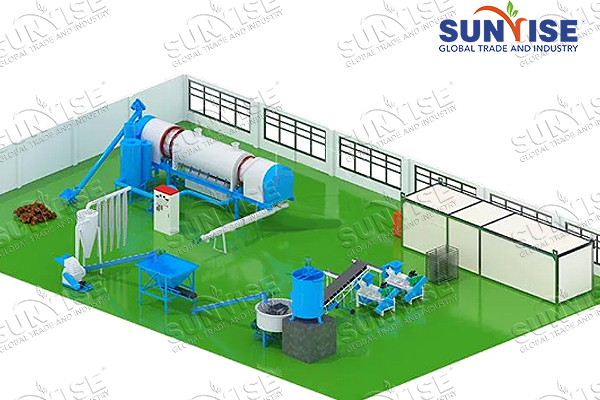

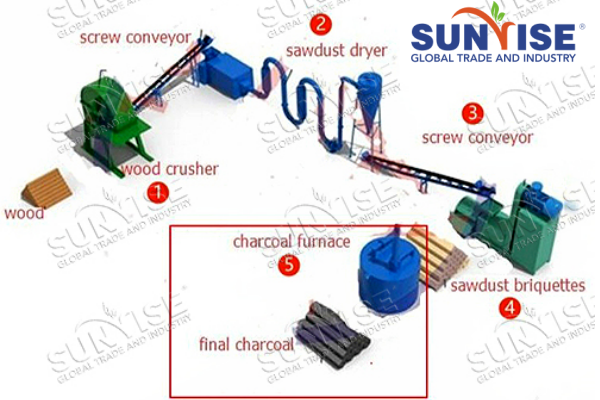

Because the Tanzanian customer required a 1000 kg/h of charcoal briquette production, the charcoal extruding line is the best choice. እዚህ, as the general charcoal briquette making plan, it main contains 8 parts according to customer’s requirements. መዶሻ ወፍጮ > sun drying > semi-conitunous carbonization furnace > ከሰል > ድርብ ሻካኖች አግድም ድብልቅ> የድንጋይ ከሰል ማሽን > sun drying > የድንጋይ ከሰል ማሸጊያ ማሽን. What different are the following 3 ገጽታዎች:

What is the price of 1000 kg/h charcoal briquette production line?

ከዚያ, on 15ሀ November, the charcoal briquette manufacturer from Tanzania came to our ዩሽኒክስ በቻይና ውስጥ የቻር-ሞለር ፋብሪካ. የከሰል ብረኪት ማሽኖቻችንን በጥልቀት ለማወቅ እና በትክክል ለማወቅ ፈልጎ ነበር። የከሰል ብሬኬት አሰራር ስርዓት ወጪዎች.

በዚህ ግንኙነት ወቅት, በቶጎ ውስጥ የድንጋይ ከሰል ፋብሪካ እንዳቋቋመ ነገረን። 2018, እና ፋብሪካን ለመገንባት እና መሳሪያዎቹን ለመተካት ፈለገ. በአጠቃላይ, ይህ የከሰል ብሬኬት ምርት መስመር ወጪዎች $70,000-$160,000. ከዚያም የግዥ ፌስቲቫል ላይ ስለሆንን ነው።, አለ 8% ቅናሽ. የመጨረሻው ጥቅስ የ 1000 ኪግ/ሰ ባዮካር ብሪኬትስ የማምረት መስመር ነው። $64,400-$147,200.

ለከሰል ብሬኬት ማሽን ምን ያህል ተቀማጭ ገንዘብ መክፈል አለብኝ?

በአጠቃላይ ሲናገር, የሚከፍሉት ተቀማጭ ገንዘብ ትልቅ ነው።, የበለጠ ቅናሽ ያገኛሉ. በከሰል ብሬኬት መሳሪያዎች ቅናሾች ውስጥ ይሁን አይሁን. እዚህ, ተጨማሪ ተቀማጭ ገንዘብ እንዲከፍሉ ይመከራል 30% የባዮካር ብሬኬት ማሽንን ሲያዝዙ. በተለይም ትልቅ መጠን ያለው የድንጋይ ከሰል ማምረቻ መሳሪያዎች. ለከሰል ብሬኬት ማሽነሪዎች የቀረው ክፍያ ከደረሰ በኋላ እልባት ሊሰጥ ይችላል።. በመጨረሻ, ከታንዛኒያ የመጣው ደንበኛ ከፍሏል። 50% በክሬዲት ሰርተፍኬት አስገባን።.