In recent years, Vietnam’s agricultural development is in good condition. Every year, a large amount of crop straw and rice husks are not fully utilized. If a charcoal briquette production line is developed, these resources can be utilized and generate high economic value. It can also increase income and save resources at the same time. لهذا, one popular plan for charcoal briquette production is charcoal extruding system. Simpler process and lower investment. Several days ago, a Vietnamese customer provided invaluable feedback on the operational efficacy of the مصنع الفحم.

Why the Vietnamese customer buy the charcoal extruding system?

The customers have own carbonization system. لكن, now the Vietnamese client plan to expand the system to charcoal briquette production to make more profits. على العموم, هناك 2 tons of charcoal generated an hour, and the moisture 5%. The customer wanted to start from a simple and low investment process. لذا, we recommended the charcoal extruding line to him.

Operational efficiency feedback of the charcoal extruding line

أما بالنسبة إلى شار ماندر, يحتاج العميل من الهند إلى قدرة 500-800 كجم/ساعة. من أجل تلبية متطلبات العميل, نوصيك بالضغط اللوحي الدوار الفحم وآلة الضغط على الشيشة.

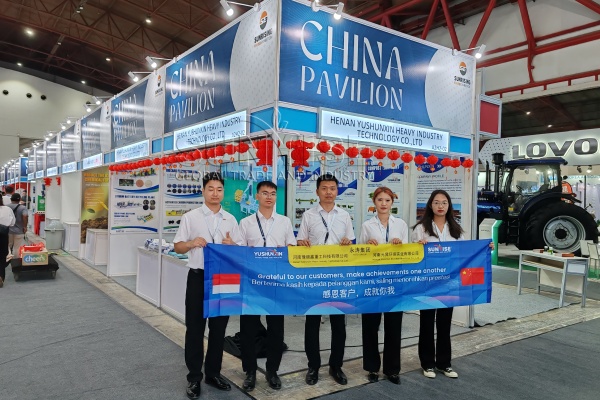

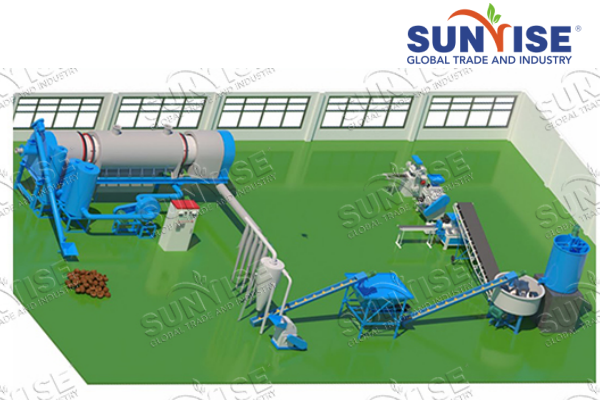

Before deciding the charcoal extruding plan, the Vietnamese guest flied to China to visit our biochar briquette machines. In the tour, from the first run, the charcoal extruding system impressed the customer with its efficiency. With simple process, the charcoal extruding line can quickly produce triangle, دائري, مربع, المستطيل, زهر البرقوق, etc charcoal briquettes from agricultural waste charcoal. It only need material feeder, طاحونة عجلة الفحم, خلاط مهاوي مزدوجة, آلة بثق الفحم و automatic packing machine.

“Now, the effective charcoal extruding line had in my factory. It can dispose of agricultural waste charcoal into biochar briquettes fast as seen in your factory.” The client praised.

Considerate guidance of biochar briquette extruding plant installation

Another point of surprise for Vietnamese customer is fast charcoal briquette equipment installation. After receiving the machines for charcoal briquette making, the installation took just under a week. لشيء واحد, the combination of charcoal extruding line is relatively straightforward. It only needs to put the equipment to corresponding place, there is nearly no parts assembly. لآخر, with the charcoal extruder equipment arriving well-packaged, complete with instructional manuals. فضلاً عن ذلك, شروق الشمس also can offer you remote or field guidance on installation, operation, etc according to your needs.

How about the ROI of forming agricultural waste charcoal with biochar extruding system?

على العموم, the investment in a 2 t/h charcoal extruding system is $75,000-$170,000. لكن, after making agricultural waste charcoal into briquettes, the can be doubled. لذلك, only takes one or even half a year, you can earn back the money spent on the charcoal extruder machines. عمومًا, as long as you replace the extruding mold once a year or half a year, this production line can produce agricultural waste charcoal briquettes for you for more than 10 سنين. The main body adopts Q235 carbon steel and the extruding molds use SUS304 stainless steel as material.

Besides the charcoal extruding line to Vietnam, we also offer many other types of charcoal briquette plants to all over world. مثل 500-800 kg/h sawdust charcoal briquette making plan, 10 t/h biochar briquette machines, إلخ: to Kenya, Brazil, الهند, Ghana, إلخ. If you plan to start a charcoal briquette plant, welcome to contact us for your own charcoal briquette production solutions.