Wood charcoal briquette making machine represents a significant advancement in sustainable energy solutions. By transforming wood waste into valuable charcoal briquettes, this innovative machinery not only promotes the efficient use of lumber by-products, but also contributes to the reduction of deforestation and waste. The charcoal briquettes produced by this plant are a superior alternative to traditional wood charcoal, offering consistent quality, higher energy density, and longer burning times. But how to dispose of wood waste well? The best way is making wood waste into biochar briquettes. This not only makes them an economical choice for heating and cooking but also minimizes the release of pollutants, thus supporting a cleaner and healthier environment. Then how to produce biochar briquette from wood waste?

What do you need to do before starting making wood charcoal briquette?

Carbonizing wood waste

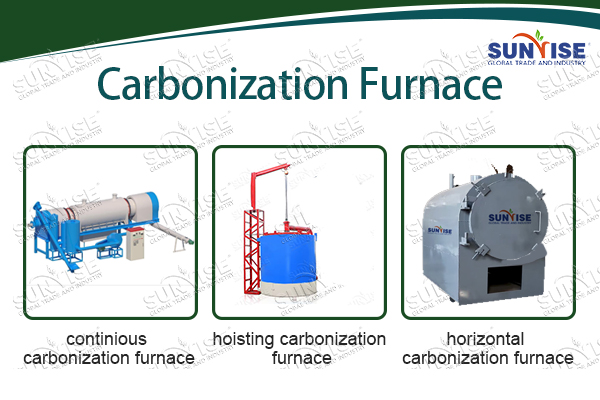

بشكل عام, wood waste not only contains sawdust, wood shavings but wood chips and pallet. But usually, materials all have different size. Too large a size will affect the carbonization effect. لذلك, it is necessary to choose a suitable فرن الكربنة. لهذا, we can provide you with hoisting, horizontal and continuous carbonization machine which have a carbonization rate of over 99%.

What is the feed materials size of carbonization machine?

If you want to adjust the size of material in carbonization machine, you can use crusher to achieve the ideal size.

Crushing carbonized wood waste

What grinding size is suitable for making high quality wood charcoal briquette?

If you want to produce high quality wood charcoal briquette, fine wood biochar powder is important. But what size is suitable for making briquette? It ranges from 1 ل 5 مم. لهذا, we recommend you some grinders. Hammer mill, Raymond mill, and wood crusher, إلخ.

How to improve the working environment during crushing?

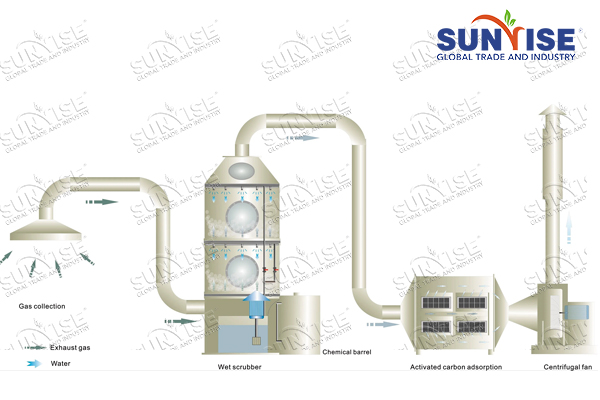

فضلاً عن ذلك, it's important to note that during crushing, a certain amount of fine dust will be generated. So you can use cyclone dust collector and spray tower to improve your working environment.

Mixing wood biochar power with binder

Charcoal power is a material totally lacking plasticity and hence needs addition of a sticking or agglomerating material to enable a briquette to be formed. Thus binder becomes a very important factor is the wood charcoal briquette making process. And pure charcoal briquette is a thing which burns with no smoke, no smell. The use of biochar briquette determines the type of binder it uses, for industry usage, there would be wider choices in binders.

What binders and additives are suitable for making wood charcoal briquette?

How to design charcoal briquettes making system for wood disposal?

For better wood disposal, many manufacturer prefer to process it to charcoal briquettes. لماذا? Because preparing wood into biochar briquettes can get more profits and provide a friendly environment. ما هو أكثر, compared to wood charcoal, briquettes are not easy to be damaged during transportation. For char-molder purchasing, there are some tips for you.

Charcoal extruder machine for 1-10 t/h wood charcoal briquette making

If you want to set up a commercial wood charcoal briquette making plant, نوصيك باختيار آلة بثق الفحم. بشكل عام, يمكن أن تنتج 1-10 tons of wood charcoal briquettes. فضلاً عن ذلك, it has characteristics of low investment, extrusion briquetting, less space occupation. Which helps you start woof charcoal briquettes making more smoothly.

Charcoal ball press equipment for 1-45 t/h wood biochar briquette production

Provided you need a machine for large scale wood charcoal briquette, charcoal ball press equipment هو أفضل خيار لك. YS-1000, the largest biochar ball press machine, has a capacity of 1-45 ذ. علاوة على ذلك, in order to prolong its service life, we especially use 65 manganese steel casting as material.

Hookah press machine & charcoal rotary tablet press

But when you want to process wood with small scale, it is advisable to buy آلة الصحافة الشيشة و الضغط اللوحي الدوار الفحم. Because it mainly makes use of the extrusion force to prepare charcoal powder into square and round briquettes. لهذا, they can make 500kg/h biochar briquettes. بهذه الطريقة, you can reduce the cost of buying machines but you can still achieve the output you want.

قمة 2 biochar briquettes molding projects for wood waste disposal

After crushing and mixing, it is time to turn wood waste into charcoal briquette you need. هنا, YS can offer you various biochar briquette production plans for your choice. They can be divided into two types: carbonize first & then form and mold first & then carbonize.

What is the quotation for wood charcoal briquette making machine?

The cost is an item most people focus on when selecting wood charcoal briquette making plan. But the price of biochar briquette making from waste usually is not fixed. It is related to many factors, especially the type of charcoal briquette and machine configuration. Then you can know the details cost of wood charcoal briquette making machine.

From the above introduction, we can learn that the configuration of wood biochar briquette production is simple. Besides charcoal briquette making machine, it only contains loader type feeder, فرن الكربنة, مطحنة المطرقة, double shafts horizontal mixer, packaging equipment, belt conveyor and so on. بشكل عام, the simpler the equipment configuration, the less the cost and the less the space occupation. لذلك, this wood charcoal briquette making machine only needs an investment of $2,000 - $100,000 and a factory area of 1,000-5,000㎡.

How to buy high quality equipment for your wood charcoal briquette making system?

After deciding your wood waste disposal plan and equipment, you also need to pay attention to quality wood charcoal briquette making machine purchasing. High quality charcoal machines have characteristics of high working efficiency, less impediment, less maintenance cost, إلخ. But how to buy quality wood biochar briquette molding equipment? There are two tips for you.