Charcoal briquette is a kind of fuel made from charcoal powder. Compared with traditional fuels, charcoal briquettes can not only generate heat continuously but also produce no smoke and odor during combustion. Per aquesta raó, it has been widely used in industrial applications in recent years and has become the most popular fuel in many countries such as Kenya, the Middle East, Uganda, India, etc.. With the increase in its economic benefits, el charcoal briquettes process has become one of the hottest processing industries. So, what are the ingredients of charcoal briquettes?

What is the composition of charcoal briquettes?

The charcoal briquette is mainly composed of two parts, the charcoal which is used to provide heat and the minor ingredients. And charcoal is the product of incomplete combustion of wood or wood raw materials or pyrolysis under the condition of air isolation. Its main component is carbon, so it can be used as fuel. Then the minor ingredients include accelerants, white ash, and briquette binder.

4 main components of biochar briquettes making from char-molder

Component 1: Charcoal

Charcoal accounts for more than 70% of the entire charcoal briquettes. As the combustion material providing heat, the raw materials for charcoal can be various woods, such as beech, birch, hard maple, pecan, and oak.

The charcoal is mainly processed by the kiln. En general, the charcoal produced and extinguished in the kiln is called black wood charcoal. It has the advantage of being easy to ignite, but it is easy to explode during burning with a short burning time and much smoke. So we don’t recommend this machine. In YS, we can provide you with other carbonization furnaces, which can produce charcoal with no smoke and a long burning time.

Component 2: Accelerants

The charcoal briquette cannot fully into contact with oxygen during the combustion process, so the accelerator is needed to accelerate the combustion. The most suitable accelerator is the nitrate, which can not only provide oxygen to accelerate combustion but also heat during combustion. No obstant això, it is too expensive. As an excellent accelerator with lower cost, you can add 10% -20% of sawdust to effectively increase the burning speed.

Component 3: White ash

As one of the minor ingredients, white ash accounts for only 2% -3% of the charcoal briquette. But it plays a very important role in the burning process of charcoal briquettes. By observing the degree of turning white, we can judge the burning degree of the charcoal briquette. A més, because the white ash is not combustible, it can effectively extend the burning time.

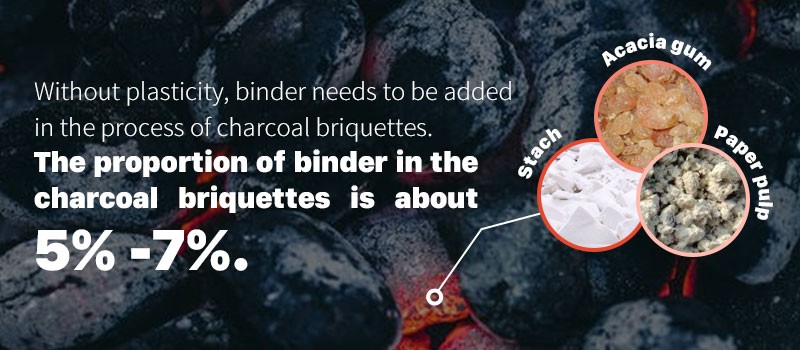

Component 4: Briquette binder

Due to the lack of plasticity, the binder needs to be added in the process of charcoal briquettes. So the proportion of binder in the charcoal briquettes is about 5% – 7%. Numerous facts show that starch has the best performance as a binding material. After it’s gelatinized, a thick paste can be formed so that the charcoal powder is stuck together to facilitate the later briquette. And another popular briquette binder is Arabic gum or acacia gum. No obstant això, considering the cost, the best choice is the waste paper pulp.