On 5th October, 2024, a customer from India inquired about how to make charcoal briquette from sawdust. "My raw materials are fresh sawdust through processing waste wood, l want the capacity of 5-8 tons per day. The budget is only $100,000, so l need the precise quote for the sawdust charcoal briquette molder price." Endlich, the Indian customer chose to buy a 500-800 Kg/H -Biokohle Brikette Making -Linie. The following are the specific details of this case:

Can the machine make fresh sawdust into biochar briquette?

Dieser japanische Kunde wollte wissen. Im Allgemeinen, es gibt Zwei Möglichkeiten zur Herstellung von Holzkohle -Brikette Aus Reisschale. Der Eine ist direkt die Reisschale in Holzkohle durch einen Karbonisierungsofen, und dann die Reisschelmkohle in Briketts komprimieren. Das andere ist es, die Reisschale zuerst in Briketts zu komprimieren, die von der Reisschießereibrikmaschine, Dann carbonisieren Sie die Reisscharze in Holzkohle.

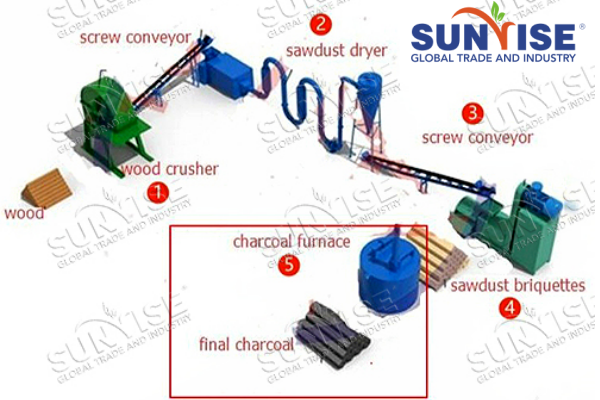

The Indian customer planned to make charcoal briquette from processing waste wood. For charcoal briquette making, you need to process waste wood into sawdust first. Then you can make sawdust into charcoal. As a reliable charcoal briquette machine manufacturer, SUNRISE also has professional carbonization furnaces for you. Einschließlich economical hoisting carbonization furnace, easy operation batch type carbonization machine Und large continuous carbonization machine.

Forming first & then carbonization

Der Feuchtigkeitsinhalt in der Reisschale hat vorhanden 15%. Jedoch, Es wird vermutet, dass der Rohmaterial haben sollte 8% Zu 10% Feuchtigkeit darin. Sie benötigen also einen Trockner, um den Feuchtigkeitsgehalt zu reduzieren. Und um die Kosten für Reishülsenbrikettierung zu senken, Es kann auch in das Sonnenlicht gelegt werden, um den Feuchtigkeitsgehalt durch Verdunstung zu verringern. Da ist die Reisschale kleiner Größe, Es gibt also keine Bedürfnisse zum Zerkleinern. Nach dem Trocknen, Sie können es direkt einspeisen Holzkohle -Extrudermaschine. Endlich, Durch Verwendung Carbonisierungsmaschine heben oder Kohlenstoffofen vom Typ Batchtyp, Sie können Reisschalen -Biokohle Brikarde bekommen.

Is there 500-800 kg/h char-molder for sawdust biochar briquette making?

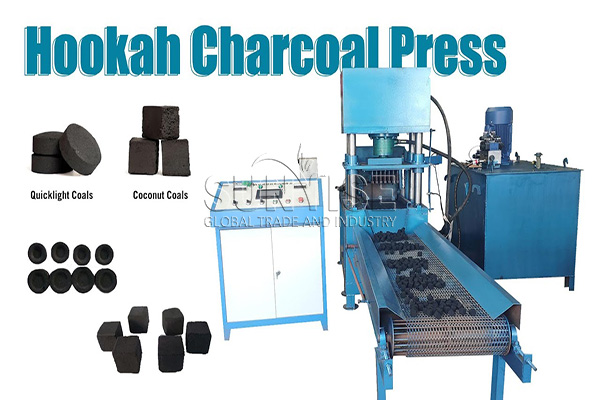

As for char-molder, the client from India required a capacity of 500-800 kg/h. In order to meet customer's requirements, we recommend you charcoal rotary tablet press and hookah press machine.

Charcoal rotary tablet press for biochar tablets making

A Holzkohle -Rotary -Tablet -Presse is ideal for small-scale charcoal briquette operations. Especially lower than 1 TPH output. Für eine Sache, high speed rotary design make it accommodate a small amount sawdust while ensuring quickly charcoal tablets making. And you can also adjust the rotary speed. Für einen anderen, this machine is made of Edelstahl material. Zusätzlich, the surface of the turntable undergoes special treatment to maintain gloss and prevent cross-contamination, in compliance with GMP requirements.

Hookah press machine for round&cube charcoal briquette production

Für 500-800 kg/h char-molder, another choice is Shisha Press Machine. For hookah press machine, we can provide you with two types: mechanical shisha biochar maker and hydraulic shisha charcoal briquette machine. They can both produce cube or round charcoal briquettes. And they usually feature an adjustable pressure control system to meet the requirements of different formulations, ensuring consistency and quality in charcoal briquette compression.

Zusätzlich, to improve final charcoal briquette quality, it is advisable to buy a 500-800 kg/h complete sawdust charcoal briquette line. Which consist of Hammermühle, Luftstromtrockner, kontinuierliche Karbonisierungsmaschine, Holzkohleradschleife, char-molder and packing equipment.

Wie viel kostet das 500-800 kg/h biochar maker price? Is $100,000 enough?

Dann, the customer paid attention to the sawdust charcoal briquette price. Allgemein, Das Zitat eines vollständigen 500-800 kg/h sawdust charcoal briquette production line with continuous carbonization machine and hookah press machine/ charcoal tablet press is $110,000-$150,000. If you need a $100,000 cost sawdust charcoal briquette machines layout with 500-800 kg/h capacity, you can choose hoisting carbonization machine or batch type carbonization machine. They only need $5,000-$7,500. But if you choose them to make sawdust charcoal briquette, it is necessary to change charcoal briquette maker. Because hoisting carbonization machine and batch type carbonization machine are suitable for columnar materials. Dafür, you need to use charcoal extruder to compress sawdust into columnar materials firstly (Only Holzkohle -Extruder meet this requirement). Then carbonizing them through hoisting and batch type carbonization machine. And charcoal extruder machine only need $3,000.

How long we can receive the sawdust charcoal briquette maker when to India?

Sawdust charcoal briquette making machines from SUNRISE to India usually needs 30-45 Tage. Because, sometimes we need 5-10 days to manufacture equipment for sawdust biochar briquette production, when the equipment is not in stock. Don't worry, we will help you receive the Holzkohle -Brikette -Ausrüstung and start sawdust biochar briquette making as soon as possible. Dafür, we receive DDP payment.

The above are details about our communication with the Indian customer about 500-800 kg/h sawdust charcoal briquette machine price. If you need the precise quote for your Holzkohle -Brikette -Produktionslinie, welcome to contact us now!