On 5th October, 2024, a customer from India inquired about how to make charcoal briquette from sawdust. “My raw materials are fresh sawdust through processing waste wood, l want the capacity of 5-8 tons per day. The budget is only $100,000, so l need the precise quote for the sawdust charcoal briquette molder price.” Lõpuks, the Indian customer chose to buy a 500-800 kg/h biochar briquette making line. The following are the specific details of this case:

Can the machine make fresh sawdust into biochar briquette?

See Jaapani klient soovis teada riisikestade biosöe briketi valmistamise meetodit. Üldiselt, on kaks söebriketi valmistamise võimalust riisi kestast. Üks neist karboniseerib riisi kestad otse karboniseerimisahju kaudu söeks, ja seejärel riisikestade söe kokkupressimine briketiks. Teine on riisikestade kokkupressimine brikettideks esmalt riisikestade briketimasinaga, seejärel karboniseerige riisikoore brikett söeks.

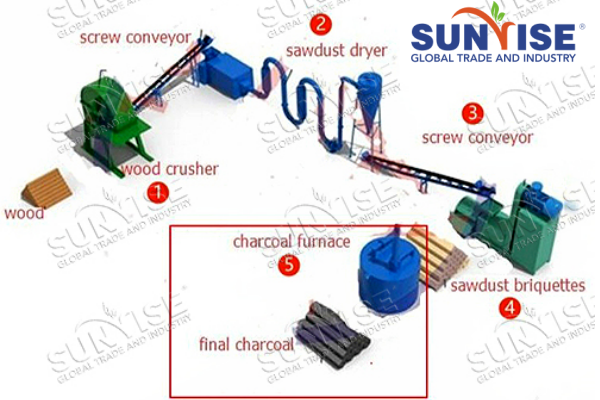

The Indian customer planned to make charcoal briquette from processing waste wood. For charcoal briquette making, you need to process waste wood into sawdust first. Then you can make sawdust into charcoal. As a reliable charcoal briquette machine manufacturer, SUNRISE also has professional carbonization furnaces for you. Including economical hoisting carbonization furnace, easy operation partii tüüpi karboniseerimismasin ja large continuous carbonization machine.

Esmalt moodustamine & seejärel karboniseerimine

Selle niiskusesisaldus riisi kestas on kuni 15%. Siiski, soovitatakse, et toorainel peaks olema 8% juurde 10% niiskust selles. Nii et niiskusesisalduse vähendamiseks on vaja kuivatit. Ja riisikestade brikettimise kulude vähendamiseks, Samuti võib selle asetada päikesevalguse kätte, et niiskusesisaldust aurustumise kaudu vähendada. Kuna riisi kest on väikese suurusega, nii et pole vaja purustada. Pärast kuivatamist, saate selle otse sisse sööta söe ekstruuderi masin. Lõpuks, kasutamise kaudu tõstev karboniseerimismasin või partii tüüpi karboniseerimisahi, saad riisikestade biosöe briketti.

Is there 500-800 kg/h char-molder for sawdust biochar briquette making?

As for char-molder, the client from India required a capacity of 500-800 kg/h. In order to meet customer’s requirements, we recommend you charcoal rotary tablet press and hookah press machine.

Charcoal rotary tablet press for biochar tablets making

A charcoal rotary tablet press is ideal for small-scale charcoal briquette operations. Especially lower than 1 TPH output. Ühe asja eest, high speed rotary design make it accommodate a small amount sawdust while ensuring quickly charcoal tablets making. And you can also adjust the rotary speed. Teise jaoks, this machine is made of roostevaba teras material. Lisaks, the surface of the turntable undergoes special treatment to maintain gloss and prevent cross-contamination, in compliance with GMP requirements.

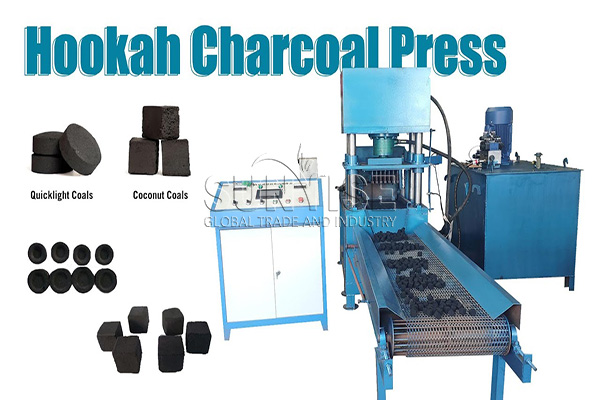

Hookah press machine for round&cube charcoal briquette production

Jaoks 500-800 kg/h char-molder, another choice is vesipiibu pressimasin. For hookah press machine, we can provide you with two types: mechanical shisha biochar maker and hydraulic shisha charcoal briquette machine. They can both produce cube or round charcoal briquettes. And they usually feature an adjustable pressure control system to meet the requirements of different formulations, ensuring consistency and quality in charcoal briquette compression.

Lisaks, to improve final charcoal briquette quality, it is advisable to buy a 500-800 kg/h complete sawdust charcoal briquette line. Which consist of hammer mill, air flow dryer, pidev karboniseerimismasin, söe ratasveski, char-molder and packing equipment.

How much does the 500-800 kg/h biochar maker price? Is $100,000 enough?

Siis, the customer paid attention to the sawdust charcoal briquette price. Üldiselt, Kogu tsitaat 500-800 kg/h sawdust charcoal briquette production line with continuous carbonization machine and hookah press machine/ charcoal tablet press is $110,000-$150,000. If you need a $100,000 cost sawdust charcoal briquette machines layout with 500-800 kg/h capacity, you can choose hoisting carbonization machine or batch type carbonization machine. They only need $5,000-$7,500. But if you choose them to make sawdust charcoal briquette, it is necessary to change charcoal briquette maker. Because hoisting carbonization machine and batch type carbonization machine are suitable for columnar materials. Selleks, you need to use charcoal extruder to compress sawdust into columnar materials firstly (Only puusöe ekstruuder meet this requirement). Then carbonizing them through hoisting and partii tüüpi karboniseerimismasin. And charcoal extruder machine only need $3,000.

How long we can receive the sawdust charcoal briquette maker when to India?

Sawdust charcoal briquette making machines from SUNRISE to India usually needs 30-45 päevad. Because, sometimes we need 5-10 days to manufacture equipment for sawdust biochar briquette production, when the equipment is not in stock. Ärge muretsege, we will help you receive the söebriketi varustus and start sawdust biochar briquette making as soon as possible. Selleks, we receive DDP payment.

The above are details about our communication with the Indian customer about 500-800 kg/h sawdust charcoal briquette machine price. If you need the precise quote for your söe briketi tootmisliin, welcome to contact us now!