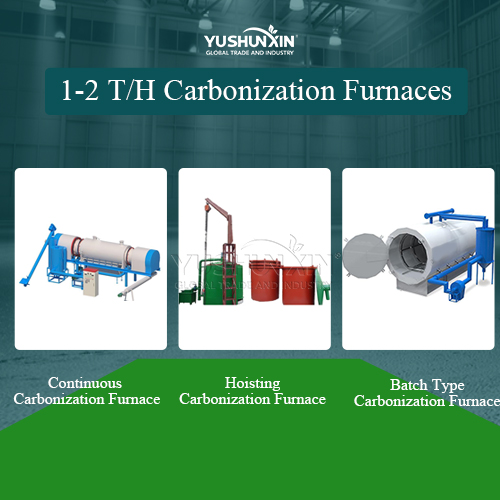

If you want to set up a 1-2 T/H charcoal briquette plant, there are two types of extrusion methods that are popular. You can choose the better one according your needs. Such as material conditions, بودجه, final charcoal briquette types, OTC. Besides buy suitable charcoal briquette equipment, you also need to focus on some other aspects in charcoal briquette production factory establishing. Including material source, factory area, certificates, OTC. اما, don’t worry YUSHUNXIN will help you start your biochar briquette making business as soon as possibility.

بالا 2 1-2 T/H charcoal briquette plant lines for your choice

برای 1-2 t/h charcoal briquette plant, we recommend you two solutions:

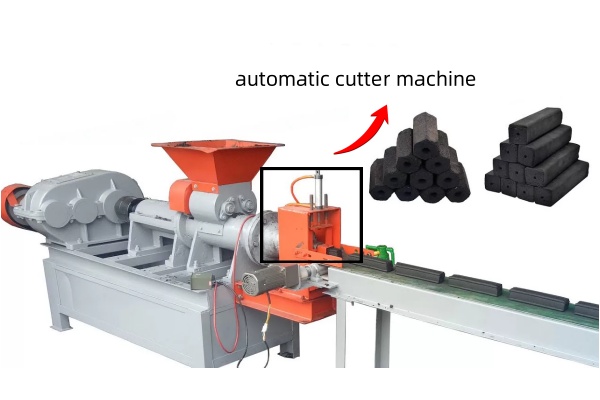

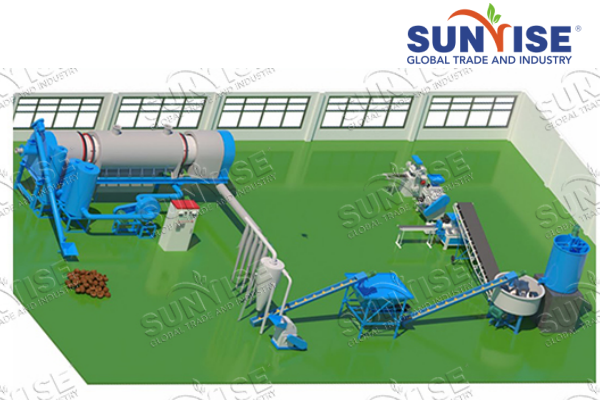

Strip type biochar briquette making with charcoal extruder

When you plan to use biomass as material to make strip charcoal briquettes, it is advisable to buy a charcoal extruding line. But if you prepare to produce square charcoal briquettes, we can also configure with cutting machine. اینقدر, the produced charcoal briquettes is also easier to transport, ذخیره و استفاده. What’s more, compared to other biochar briquette machines, it has a smaller area occupation and higher briquette rate (over 93%). And there are 5 models of charcoal extruders for 1-2 t/h charcoal briquettes output. اینقدر, they can fully meet your requirements for small scale charcoal briquette plant setup.

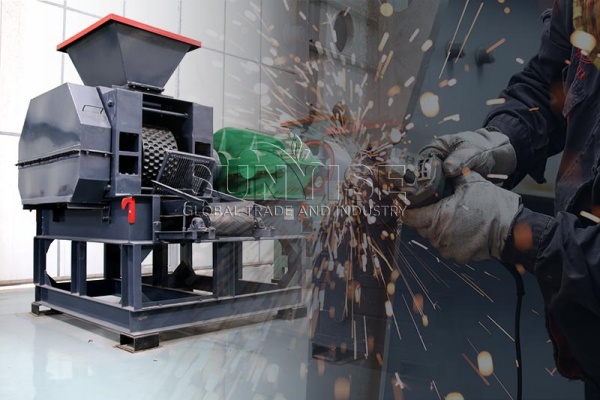

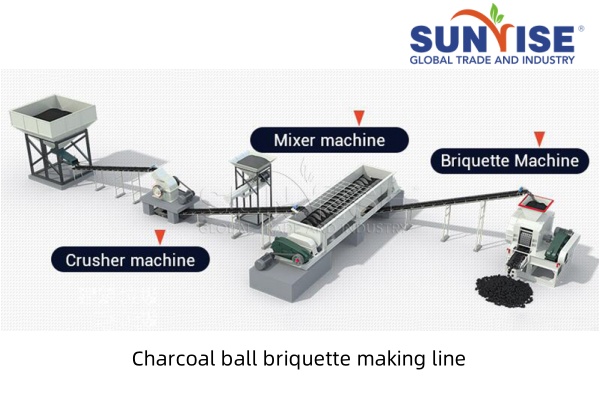

Economical biochar forming with charcoal ball press machine

اما, for those who want to use dry material to make charcoal balls directly, there is a solution with lower investment. It is charcoal ball press line. در این روند, charcoal powder mainly relies on the extrusion force between rollers to form into charcoal pellets. There is nearly no water involved and the feeding material moisture is 5%-10%. اینقدر, it has no need of dryer and cooler for charcoal balls drying. In terms of charcoal balls making cost, you can save the money on dryer purchasing. For start a 1-2 t/h charcoal briquette plant, we also design 8 types of charcoal ball press machines برای انتخاب شما.

What is the cost of 1-2 t/h charcoal briquette production lines?

همانطور که در بالا ذکر شد, both charcoal extruding line and charcoal ball press system need a low investment. هر چند, the precise quote of 1-2 t/h charcoal briquette plant is depended on the configuration.

How to produce 1-2 t/h charcoal briquette at a lower cost?

If you need a solution for 1-2 t/h charcoal briquette making with lower cost, we also provide you a simpler process. Such as only charcoal wheel grinder+char-molder+automatic bagging machine. (نکات: your material is charcoal!)

How about the produced biochar briquette quality?

Then, buy equipment for your 1-2 t/h charcoal briquette plant, the decisive factor is produced charcoal briquette. ls it what you need in size, shape or hardness?

What other items we need to focus on when setup a 1-2 t/h charcoal briquette plant?

Setting up a 1-2 t/h charcoal briquette plant involves more than just suitable دارندگان buying. You also need to determine the recipe for charcoal briquettes making, ensuring a stable material source, finding a suitable factory area, and obtaining necessary qualifications and even more.

Is there successful 1-2 t/h charcoal briquette plant cases?

البته البته. As a charcoal briquette machine factory with over 20 years, یوزونکسین 1-2 t/h biochar briquette making plan have helped many charcoal briquettes suppliers start their business all the world, including Malaysia, کنیا, India, Germany, Mauritius, OTC.

در کنار, charcoal briquette making solutions for 1-2 t/h output, we also can offer you for other capacities. مانند 500 kg/h charcoal briquette making machine proposal, 3 t/h biochar briquette production or even 10 T/H, 30 T/H, OTC. Welcome to contact us for your own charcoal briquette making plan now.