Is there a business plan for large scale biochar briquette manufacturing. Bien sûr. We can provide you with 300,000 t/y charcoal forming project. And in terms of hourly output, it can reach 10 ème. So it can fully meet your requirement of commercial charcoal briquette making in large quantities. En outre, according to the needs of different charcoal briquette manufacturers, we especially design various 300,000 t/y charcoal briquette preparation systems. Tel que 300,000 t/y charcoal production system, 300,000 t/y biochar briquette line, 300,000 t/y charcoal briquette packaging system, etc.. If you have any other requirements, Vous pouvez nous contacter immédiatement, we will offer you the best biochar briquette making solutions.

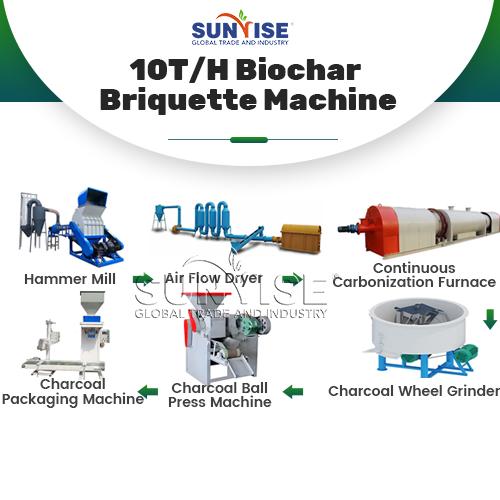

How to start 10 t/h biochar briquette making project?

If you want to turn biomass materials (cosse de riz, bambou, sciure, etc.) into charcoal briquettes in a large scale, you can choose our 10 ème biochar production project. Dans ce processus, you need to three steps:

Crushing biomass materials into fine powder

Ici, crushing biomass material into fine powder is an ideal choice to facilitate material drying. Because the smaller the particle size, the larger the contact area with drying. Then because of the large capacity of 10 ème, Nous vous recommandons de choisir YS-800 hammer mill. It not only has a large output but also can grind large amounts of biomass materials into fine powder without again.

Adjusting moisture content

En général, raw material moisture content plays an important role in charcoal briquette making. Because moisture can affect the bonding between raw materials. Too much moisture may cause the raw materials to become too wet, reducing their bonding ability and making the charcoal briquette not strong enough. Donc, it is advisable to adjust the moisture to 5%-15% before biochar briquette production. And using YS large scale rotary dryer machine is a more effective method. Mais si votre matériau est de la sciure, we can also provide you with air flow dryer which is more suitable for drying smaller pieces.

Using continuous carbonization furnace

De plus, you need to purchase a suitable carbonization machine. For large scale biochar making, four à carbonisation continue is the best option. Pour une chose, its capacity is 1000 kg/h with continuous production, which is far more than other carbonization machines. So it can help you finish 300,000 t/y biochar briquette production project quickly. Pour un autre, this equipment adopts a fully automated electrical control system. During the working process, even without any operation, it can turn biomass material into biochar.

Conseils: Lorsque vous utilisez cette machine pour produire du charbon de bois, nous suggérons la taille des matériaux ne dépassant pas 50 mm. Bien que le four rotatif de carbonisation ait pour fonction de sécher, nous ne suggérons pas de carboniser directement les matériaux humides, cela affectera l'efficacité de la carbonisation et la qualité du charbon de bois. Il est donc préférable de s'assurer que l'humidité des matériaux est inférieure à 30%. So you need to process biomass materials in advance.

What equipment is used in large scale biochar briquette production?

Is there charcoal briquette making plan for further process biochar? The answer is yes. If you have completed the biochar, you can purchase 300,000 t/y charcoal briquette line directly. During 300,000 t/y charcoal briquette making, you may need equipment: Machine de presse à balle au charbon de bois, broyeur de roue au charbon de bois.

10T/H packaging system for your finished biochar briquettes processing

When you have finished biochar briquette making and want to sell to your customers, it is advisable to use our packaging system for large scale charcoal briquette manufacturing. Because in this system,

Automatic charcoal bagging equipment can help you package finished charcoal briquettes into 10 kg / sac, 15 kg / sac, 30 kg / sac, 50 kg/bag and 65 kg / sac, etc.. So you can sell charcoal briquettes to your customers in a targeted way. For capacity of 300,000 tons per year, YS especially design round hookah charcoal packing machine, cube shisha biochar packing machine, BBQ charcoal packing machine and honeycomb briquette bagging equipment for your choice.

And there are some other machines equipped with round hookah charcoal packing machine. Hookah charcoal dispenser and heat shrink packaging machine. Hookah charcoal dispenser’s tracks allow the individual products to be separated. And heat shrink packaging machine can add plastic film to the outside of the product can prevent the box from scratching and also prevent moisture. So they can both help you package charcoal briquettes. You can choose them according to your budget.

How much does the large scale biochar briquette making machine cost?