On 24th March 2024, we received a wood charcoal briquette manufacturer customer from Romania in our factory. The client is interested in hexagonal charcoal briquette making line including pressing, cutter & dryer and discusses the layout of his 1-2 MT/h wood charcoal briquette production line. And he is from Halupex company, in order to further improve the profits of charcoal briquette making, the customer plans to expand the business to the manufacturing of wood biochar briquette.

Which wood char-molder is suitable for 1-2 MT per hour output?

The Romanian customer told us that they were looking at capacities of 1 da 2 MT per hour. And on 300 days wood charcoal briquette production basis. Menene mafi, the requirement of customer is hexagonal charcoal briquette production. Don wannan, there is a charcoal molder that is suitable for you to turn wood into biochar briquette.

YS-140 charcoal extruder machine-hexagonal biochar briquette

For better hexagonal biochar briquette manufacturing with a 1-2 t/h capacity, A bu mai kyau saya injin gawayi. Because compared to other char-molders of biochar briquette production, it can help you convert wood into charcoal briquette with two briquetting methods. And this machine has a lower cost for wood charcoal briquette production. Bugu da kari, itself configure cutter for final product to control length.

| Abin ƙwatanci | Ys-140 | Ys-180 | YS-210 | Ys-300 | YS-400 |

|---|---|---|---|---|---|

| Iya aiki | 1-2 t / h | 2-3 t / h | 3-4 t / h | 3-5 t / h | 6-10 t / h |

| Musali Daidai | 20-40 | 20-60 | 20-80 | 20-80 | 20-80 |

| Saurin Mainshaft | 46-60 R / Min | 39-60 R / Min | 35-60 R / Min | 35-60 R / Min | 35-60 R / Min |

| Yawan launuka na karkata | 4 | 4 | 4 | 4 | 4 |

| Kayan lantarki | Y160M-4 11KW

Y160L-4 15KW |

Y180M-4 18.5KW

Y180l-4 22kw |

Y200L-4 30kW

Y225G-4 37kW |

Y225G-4 37kW

Y225m-4 45kw |

Y315m-4 160kw |

| Raguwa | ZQ350 | ZQ400 | ZQ500 | ZQ650-750 | ZQ850 |

What briquetting method can achieve wood charcoal briquette making?

After recommending rod making machine, the customer from Romania asked us that what briquetting method is suitable for it. Haƙiƙa, there are two methods for your choice.

What other equipment can help you make high quality wood biochar briquette?

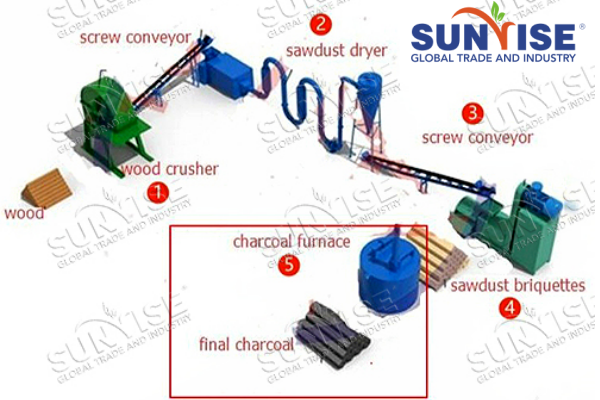

Because this Romanian client is interested in hexagonal charcoal briquette making line. Except charcoal extruder machine, there are other machines you need to pay attention to.

Charcoal grinder machine

Whether you are crushing charcoal or wood, this device is indispensable. Haka, if you want to crush wood, we recommend you use a hammer mill. For biochar grinding, charcoal wheel grinder is more suitable.

Drying equipment

After briquetting, the final product has more danshi. And excessive moisture content can affect the burning efficiency and quality of wood charcoal briquette. Saboda haka, proper drying is usually performed before use. Don wannan, we recommend you choose mesh belt dryer, which can reduce the moisture of wood biochar briquette below 1%.

How much floor space does a 1-2 t/h wood charcoal forming line occupy?

The floor space of the wood charcoal forming line mainly depends on the arrangement of the equipment, the design of the plant and the material transportation method. According to the Romanian customer’s output of 1-2t/h, the floor space of this production line is roughly between 150-200㎡, mai bi:

Hoisting Carbonization Injin: about 10-30㎡(Depends on model and quantity)

Gawayi da grinder: about 5-8㎡

Injin gawayi: about 6-10㎡

Biochar packaging equipment: about 5-8㎡

Raw material storage and finished product storage area: about 30-50㎡

You need to reserve space for equipment maintenance, manual operation and material transportation, which usually accounts for 30%-50%.

Compact layout: 80-120㎡

Standard layout: 150㎡

Long layout: 150-200㎡

The above are details about our communication with the customer about wood charcoal briquette manufacturing machine in Romania. Bugu da kari, if you want to make other types of charcoal briquettes, we also can provide you with suitable charcoal briquette making business plans. Kamar bamboo biochar briquette plant, coconut shell charcoal briquette line, riƙaƙa.