A cikin kwanannan, Kasancewar gawayi na gargajiya yana raguwa. Amma bukatun sa ya yi girma yayin da ake iyakance. Jera saboda tsawan gandun daji da sha'awar kiyaye bishiyoyi. Saboda, gawayi ya zama mashahuri a yau. Kuma fara wani aikin gawayi ya kasance mai amfani aiki a cikin ƙasashe da yawa, Kamar Afirka ta Kudu, Unganda, Kenya, da sauransu. Don wannan, a ranar 19 ga Afrilu 2024, Mun sami Briquette na Briquette yana yin abokin ciniki daga Kenya. Wannan abokin ciniki yana so ya sanya Briquette Briquette daga Sawdust. Amma bai san abin da samarwa yake ba shine. Wadannan sune cikakken bayani game da wannan yanayin:

Why Is Sawdust Charcoal Briquette Making Popular in Kenya?

Kenya has long relied on traditional wood charcoal for cooking and heating, but with increasing deforestation and the rising cost of fuel, the search for alternative energy sources has become urgent. In recent years, producing charcoal briquettes from sawdust has gained popularity across the country. This eco-friendly solution not only reduces waste but also provides a sustainable source of income and energy for local communities.

Kenya’s furniture and timber industries generate large amounts of sawdust every day, most of which used to be burned or dumped. By converting this waste into charcoal briquettes, manufacturers can turn low-value residues into high-value fuel. This process helps reduce environmental pollution and promotes circular economy practices.

The Kenyan government encourages renewable energy initiatives and sustainable waste management. Projects that convert agricultural and wood waste into briquettes align with national clean energy goals and often receive support from NGOs and local authorities. This favorable policy environment makes sawdust charcoal production even more attractive to entrepreneurs.

With urban populations expanding and traditional charcoal prices increasing, demand for cheaper and cleaner fuel is growing rapidly. Sawdust charcoal briquettes burn longer, produce less smoke, and are more affordable for households, restaurants, and small industries-making them an ideal alternative in both rural and urban markets.

What Kind of Sawdust Is Used for Making Briquettes in Kenya?

Quality Requirements for Sawdust

The quality of sawdust has a direct impact on the strength, burning efficiency, and appearance of briquettes. Clean and uniform sawdust leads to higher carbonization efficiency and better compression during molding. The raw material should be free from paint, varnish, or chemical residues, as these can produce toxic gases during combustion. Finer particles are preferred because they fill molds evenly and bind more tightly under pressure. Choosing pure, uncontaminated sawdust ensures that the final briquettes are safe, yar kamanta, and environmentally friendly.

How to Control the Moisture Content of Sawdust

Moisture control is one of the most critical factors in briquette production. The ideal moisture content of sawdust is between 8% da 12%. If the material is too wet, the briquettes will not hold their shape and will take longer to dry after pressing. A wannan bangaren, overly dry sawdust lacks flexibility and reduces the bonding strength between particles.

To achieve the right balance, producers often dry sawdust under the sun or use a rotary drum dryer for faster and more consistent results. During rainy seasons, storing sawdust under a covered shed and using airflow dryers helps prevent moisture absorption. Regularly checking the material’s moisture level before carbonization or briquetting ensures stable production and high-quality briquettes.

What is the Process of Making Biochar Briquette from Sawdust?

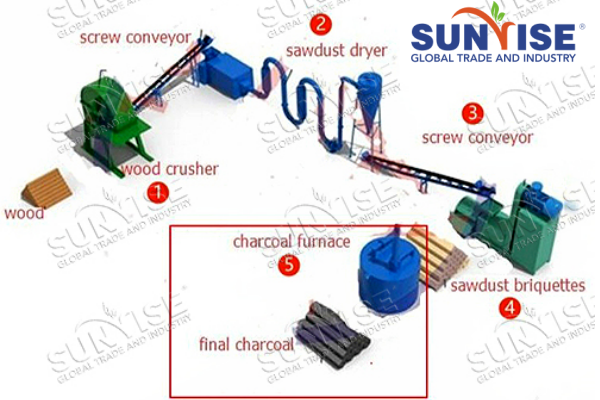

Wannan abokin ciniki na Kenya ya so ya san aiwatar da samar da Sawdust bicar briquar. Gabaɗaya, Akwai 4 matakai a cikin samar da sawdust charcoal briquette.

What is the Advantage of Making Sawdust Charcoal Briquette?

Daga bisani, Abokin ciniki daga Kenya ya shirya yin sawdust gawayi. Amma ya damu cewa ribar ba zai zama mai kyau kamar siyar da sawcaal na zahiri ba. Mun yi masa bayanin shi da fa'idodi na sarrafa sawdustte.

How Much Does a Small&Large Scale Sawdust Charcoal Briquette Plant Cost?

Kyakyawan suna taka muhimmiyar rawa a cikin gawayi na gawayi. Farashin Sawdust Bioquar Brittette in karuwa tare da damar. Wannan Abokin Ciniki na Kenya ya so mu ba shi tsari mai farashi.

How Much Does It Cost to Start a Sawdust Charcoal Briquette Business in Kenya?

Starting a charcoal briquette business in Kenya is one of the most promising clean energy investments today. With abundant sawdust from furniture and wood industries, and growing demand for eco-friendly fuels, our customer is turning this waste into profit. Duk da haka, before launching your briquette project, it’s crucial to understand the initial investment, machine cost, and expected returns.

What Are the Main Costs of Setting Up a Sawdust Charcoal Briquette Factory?

Establishing a sawdust charcoal briquette production line involves expenses for equipment, shigarwa, site preparation, labor, and electricity. The cost largely depends on your desired production capacity and automation level.

| Cost Category | Description | Estimated Cost Range |

| Installation & Commissioning | Machinery setup, test running and technician guidance | $2,000-$10,000 |

| Site Preparation | Factory building, foundation work, ventilation and layout design | $5,000-$30,000 |

| Labor Cost | Operators, technicians and management staff salaries | $2,000-$10,000/month |

| Electricity & Fuel | Power consumption for machines and heat source for drying and carbonization | $1,000-$5,000/month |

| Kayan kayan abinci | Sawdust, Kayan itace, rice husk or other biomass feedstock | $500-$3,000/month |

| Transportation | Shipping of equipment and raw materials | $1,000-$8,000 |

| Maintenance & Spare Parts | Replacement parts, regular machine maintenance and lubricant | $1,000-$3,000/year |

| Miscellaneous | Licenses, taxes, safety equipment, office supplies, riƙaƙa | $1,000-$5,000 |

What Factors Influence the Total Investment of Sawdust Charcoal Briquette Production?

Several factors affect your total startup cost beyond the machines themselves.

Kai 3 Carbonization Machines for Sawdust Charcoal Briquettes Making

Bayan an tattauna tsarin, Abokin Ciniki na Kenya ya so ya san wanda ya fi ƙarfin bugun kirji don samar da gawayi.

Hoisting Carbonization Injin

Da hoisting carbonizit tfinace ya hada da mai lantarki. Tare da mai lantarki, Zai iya ɗaukar tanki na ciki a sauƙaƙe, wanda ke ceci farashin aiki. Kuma kowane murnanda aka sanye da shi 3 Tankalin ciki. Lokacin carbonizing lokacin ne 8-12 sa'o'i don tabbatar da ingancin gawayi. Bayan tanki daya na kayan da ya cika carbonization, Kuna iya ɗaga shi ta hanyar hoist sannan ku sanya wani tanki na kayan don caji.

A kwance carbonization tnernace

Madaidaiciya carbonization inji Yana ɗaukar ƙirar kwance don rage tsayin daka. Don haka ya fi dacewa da loda kayan abinci. Kuma kuma ya haɗa da tsarin maimaita hayaƙi. Hayaki da aka kirkiro a cikin tsarin carbanizing ya shiga mai tsarkakewa sannan a kunna shi don dumama tanderu. Menene mafi, Yana fitar da gawayi ta tsari, lokacin carbizing 8-10 sa'ad da, Lokacin sanyaya ruwa 2-3 sa'ad da, sanyaya iska 6-8 sa'ad da.

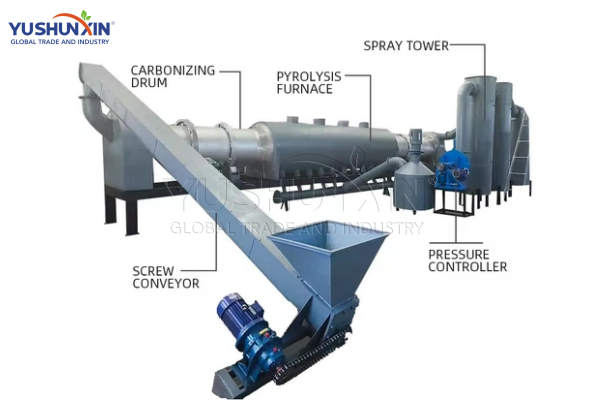

Ci gaba da kayan aikin carbonization

Ci gaba da farfadozar carboniz ya dace da caji kayan biomass waɗanda suke cikin ƙananan guda. Lokacin da kake amfani da wannan injin don samar da gawayi, Muna ba da shawarar girman kayan ba ya fi girma 50mm. Kodayake carbonization rotary na damin yana da aikin bushewa, Ba mu ba da shawarar carbonizing kayan rigar kai tsaye, Zai shafi carbonizing ingantaccen da ingancin gawayi. Don haka yana da kyau a tabbatar cewa danshi kayan ƙasa da 30%.

Testing Report of Sawdust Biochar Briquette Made from Charcoal Molding Machine

Anan mun zaɓi Sinawa Sawdust na cikin gida don gwada ingancin sawdust gawayi. Rahoton ya nuna cewa darajar yawan adadin gawayi na gawayi da Briquette da aka samar ta hanyar gawayi na Briquette na'urar ya wuce 6000 kcal / kg, kusan sau biyu na raw sawdust (yawanci 3000-4500 kcal / kg). Wannan kyakkyawan aikin ya sa sawdust gawayi mai dogaro da ingantaccen makamashi tare da fa'idodin tattalin arziƙi. Saboda haka, da gaske ba da shawarar cewa abokin ciniki yayi la'akari da wannan aikin.

|

M |

Sawdust |

|---|---|

| Jimlar danshi MT% |

6.84 |

| Mai binciken ruwa mai zurfi |

4.51 |

| Bushe tushen AD% |

5.871 |

| Volatile kwayoyin a kan busassun tushe vd% |

20.8 |

| Kafaffen carbon FCAD% |

68.91 |

| Abun ciki na sulfur a kan busasshen tushe St.D% |

0.08 |

| New Kungiyar Calorimeter busasshen Calorimeter busassi mai ƙarfi mai inganci KCal / KG |

6454 |

| Sabuwar ƙa'idodin ƙasa na Kasa na Calormimeter na ƙasa yana karɓar tushe mara ƙarancin ƙimar kcal / kg |

6088 |

Wasiƙa: Iri daban-daban, danshi, Girman kayan albarkatun kasa, da sigogi masu fasaha zasuyi tasiri a kan sakamakon caromization na Biomass.

Feasibility and ROI of Investment in Sawdust Charcoal Briquette Project

Abubuwa da yawa suna bayar da gudummawa ga masu binciken riba na saka hannun jari a aikin samar da gawayi na sawcaal. Yanzu, Bari mu shiga wannan saka hannun jari ga abokin ciniki na Kenya.

Abubuwan da ke sama sune cikakkun bayanai game da yadda ake yin gawayi daga sawdust a Kenya. Ban da, Hakanan muna iya ba ku sauran charcoal briquette layin samarwa. Kamar 3 t / h sawdust gawayi briquette inji, Bbq biocark briquette yin shuka da bamboo gawayi, riƙaƙa.