Biochar production equipment carbonizes organic materials into charcoal through a series of reactions. The main final product, biochar, is a kind of green energy. Because it has the characteristics of high calorific value, long burning time, and minimal smoke emissions. So the biochar production business is an ideal environmental project that is worthy of investing in.

What is the biochar production equipment?

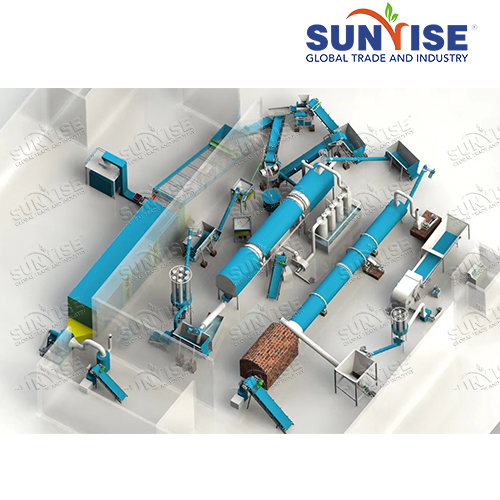

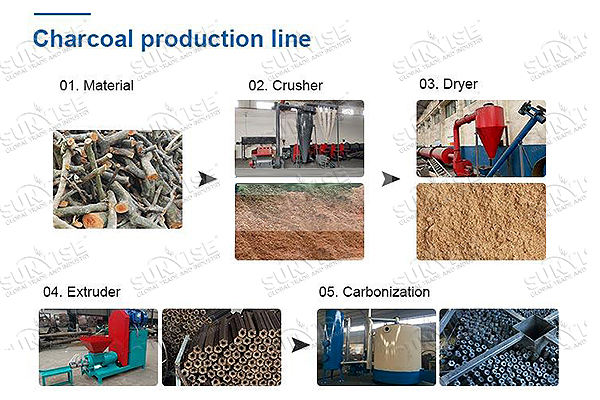

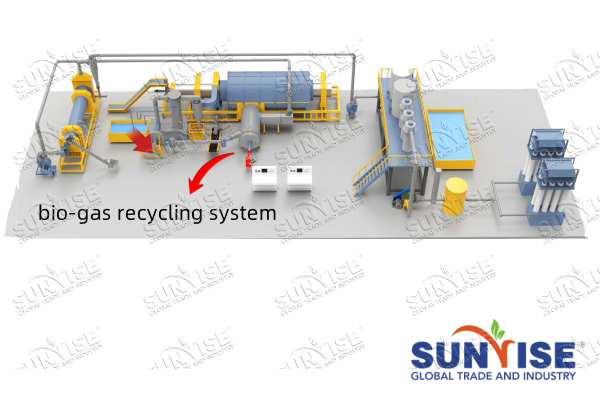

Biochar production machine usually includes single charcoal machines and complete processing lines. Regardless of the scale of charcoal plants opened by charcoal processors, they usually need to use a certain number of charcoal machines to complete the production. ʻo kahi laʻana, sawdust making machine, sawdust dryer, briquette machine, ʻO Fesnace Fesnace, etc. They all play an important role in the process of charcoal production.

Why people want to invest charcoal production line?

This cost-effective charcoal production line enables customers to acquire select equipment for biochar production. Whether you are just stepping into the charcoal industry or running a small scale biochar factory aiming to increase production, this commercial proposal offers a solution that matches your needs and budget.

How much space does a charcoal production line require?

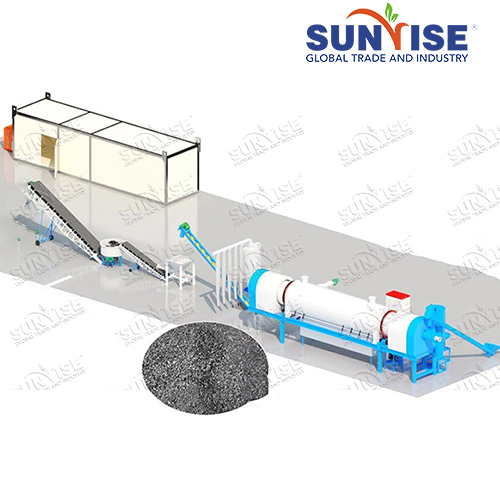

Are you new to the biochar industry and considering establishing your own plant? If you’re a medium scale charcoal factory aiming to produce between 500 i 1000 kg of biochar per hour, a biochar production line with an annual output of less than 864 tons could be the ideal choice for you. Meanwhile, you just need to keep in mind that setting up such a facility requires a little amount of equipment and space.

This biochar production equipment may require 350-1050 square meters of land by selecting specific important equipment for configuration. This line setup would encompass essential components for charcoal manufacturing while optimizing space utilization efficiently. By focusing on essential machines from crushing to carbonization, you can set up a charcoal making line to enable the manufacturing of biochar while minimizing land and budget.

What is the budget for setting up a biochar production line?

What equipment for charcoal production line you can choose?

When you setup a charcoal production system, the selection of equipment plays an important role in effectively making biochar within a limited space. Here are the equipment options:

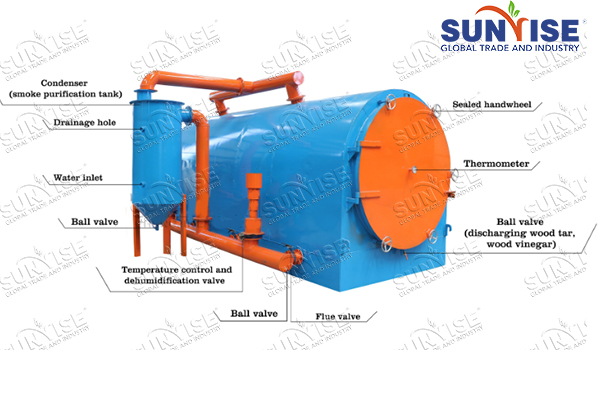

What is the design of biochar production equipment?

In order to be able to meet the needs of different customers, we have deliberately upgraded our products. To do this, we have some unique designs for our equipment.

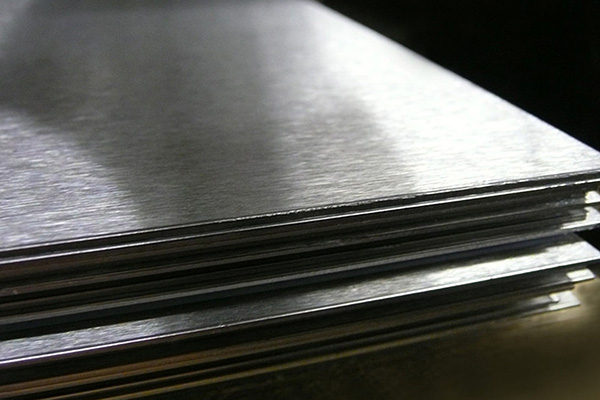

Durable 310s stainless steel material

The reactor of biochar equipment is made of a special 310s stainless steel material (austenitic stainless steel). It has good high temperature resistance, abrasive resistance, and corrosion resistance. And it can also bear 750-850℃ high temperatures. So its service life can reach 5-8 years and it can work 5500-5800 hours per year.

Horizontal design

The charcoal machine has a horizontal type design. With such a design, the hot air will not contact with the bottom of the furnace directly. So it can reduce the damage to the furnace.