Hōʻikeʻo Sunrise i ka hōʻikeʻo Charcoil Briquette ma Indonesia

On 29nd – 31th July, 2024, this is a grand exhibition of ʻO ka mīkini uila Braquettette in Indonesia. This year, the exhibition was graced by the presence of SUNRISE, a prominent name in the Char-Molder manufacturing industry. We bring our the latest technologies and machines of biochar briquette production. Welcome to visit our booth to get the best charcoal briquette making system for you immediately.

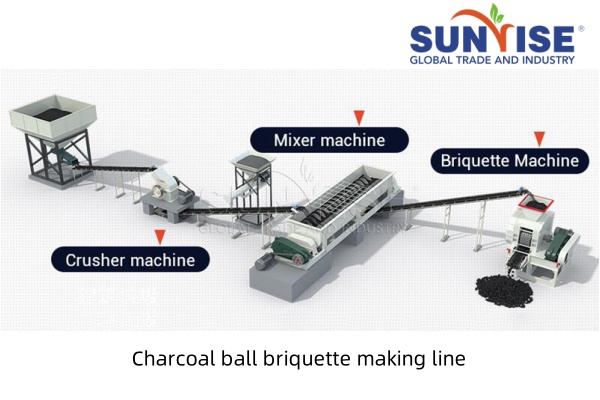

Advanced Charcoal Briquette Making Machine Of SUNRISE In Indonesia Exhibition

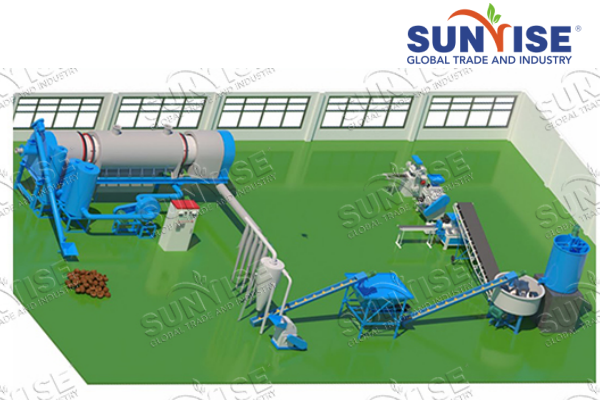

SUNRISE, known for its cutting-edge solutions in charcoal briquette production, has various advanced machinery and equipment of industrial biochar briquette manufacturing. Such as bamboo charcoal briquette production lines, sawdust biochar briquette machines, a wood charcoal briquette making system. All our charcoal briquette equipment on display has energy efficiency, robust design, and innovative features. Pela, they can help you optimize the biochar briquette production process and prepare quality charcoal briquette quickly and easily.

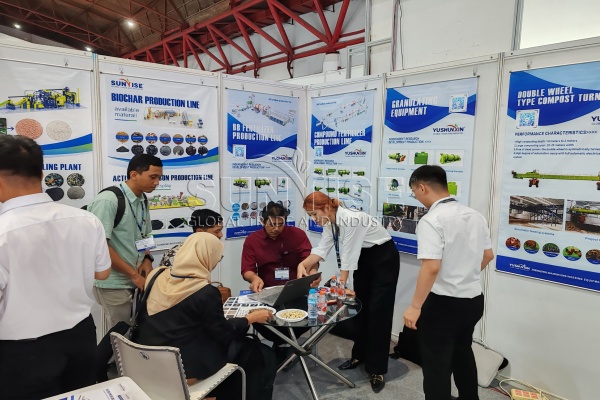

Charcoal Briquette Makers Were Interested In SUNRISE Char-Molder

During the Indonesia exhibition, SUNRISE to interact with a diverse audience comprising potential clients, industry experts, and competitors. Ma kēia kaʻina hana, many charcoal briquette suppliers from various areas are interested in our equipment for both bamboo charcoal briquette making and sawdust biochar briquette production. Including Morocco, Poland, Malaia, etc. Our engineers discussed the details of char-molder equipment and designed customized charcoal briquette making plans for your choice.

Develop Our New Customer for Buying Bamboo Charcoal Briquette Plant

Kahi mea hou aʻe, our engineers developed many new customers at this Indonesian exhibition. Many of them are interested in bamboo charcoal briquette production line. Customers are ready to produce bamboo charcoal briquette from kupai hoi waste. And the final product is rod shape bamboo biochar briquette. The charcoal briquette manufacturers told us, he hoped this system help him to dispose of spent bamboo waste quickly and produce high quality charcoal briquette which can get more profits. Hope loa, we reached a friendly cooperation.

What is the Process of Making Bamboo Charcoal Briquette from Bamboo Waste?

'Ōlelo process of making bamboo biochar briquette from bamboo waste is both eco-friendly and cost-effective. Here’s a simplified outline of the process: