Quando vuoi scegliere un adatto Creatore di bricchette a carbone, Devi conoscere i loro design per realizzare bricchette di alta qualità. In Ys, Possiamo offrirti con 3 Tipi di macchine per la creazione di bricchette biochar, che hanno rispettivi design. Le seguenti sono le informazioni dettagliate:

N.1 Attrezzatura di stampaggio a carbone a canna

Se si seleziona per preparare bricchette a carbone, Devi capire che quali design possono creare pellet di biochar di alta qualità.

Le dimensioni e l'umidità dei materiali di alimentazione

La dimensione dei materiali di alimentazione ideale è inferiore a 3 mm. Se i tuoi materiali sono troppo grandi, Puoi usare la smerigliatrice per smaltire i materiali. E 10-14% è la migliore umidità per la creazione di bricchette Extrusder briquette a carbone. Con bassa umidità, L'attrito sarà più grande, il che rende l'uscita della bricchetta più lenta, la bricchetta con alto umidità sarà più morbido e richiede più tempo per asciugare.

Alta densità e resistenza

Extrusione Briquette Maker è una specie di macchina per bricchette a vite fa una pressione elevata rispetto ad un'altra macchina per la bricchetta. E la pressione comune dell'estrusore di bricchette di carbone è 35 MPA. Quindi il materiale rimarrà molto più a lungo in Briquette Extrusder (La velocità di uscita per la bricchetta normalmente è 20-40 mm/s ) con il quale rende il palazzo briquette.

N.2 macchina per pressione a sfera di carbone

Quando vuoi fare la palla, cuscino, Briquette biochar quadrate e lath, Puoi scegliere questo produttore di bricchette biochar. Ma qual è il design di Roller Briquette Press Machine?

Dimensione della palla regolabile

Qual è la dimensione della palla finale prodotta da Roller Charcoal Briquette Press Equipment? Questo è un articolo su cui si concentra la maggior parte dei produttori di bricchette. Generalmente, La nostra macchina da pressa a sfera di biochar può preparare bricchette con un diametro di 25-50 mm. Questo può soddisfare appieno le tue esigenze.

Dimensione dei materiali e contenuto di umidità adatti

Se vuoi preparare una palla di carbone di alta qualità, Il materiale adatto è essenziale. Generalmente, La dimensione del materiale è sotto 5 mm. E il contenuto di umidità è tra 7-15%. Quindi quando si prepara ad aggiungere alcuni leganti nel processo di pressione della sfera di carbone, L'umidità sarà diversa.

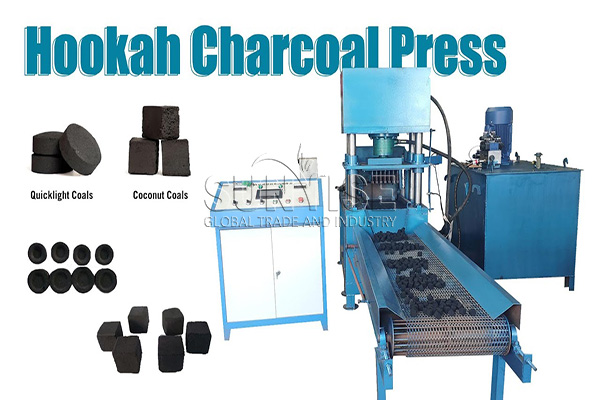

No.3 Attrezzatura per la stampa di narghilè

Perché questa macchina produce principalmente briquette di biochar shisha, Quindi progettiamo questa macchina secondo il prodotto finale.

Vari modanature per la tua scelta

Le forme di Shisha Charcoal Briquettes possono essere cubiche, diamante, anello, romboide, forma triangolare, cilindro, piramide, convessità, concavità, compresse rotonde, ecc. Quindi progettiamo tipi di stampi per la tua scelta. E possiamo anche fornirti un servizio di personalizzazione in base alle tue esigenze. I diametri finali del prodotto sono circa 30-40 mm con forma rotonda e 20-25 mm con forma del cubo.

Tipi meccanici e idraulici

Esistono due tipi di Macchine per la stampa di caveoh per la tua scelta. Tipo meccanico e idraulico. Possono usare diverse pressioni per realizzare bricchette di carbone di alito di alta qualità. Puoi sceglierli in base alle tue esigenze.