近年では, Vietnam's agricultural development is in good condition. 毎年, 大量の収穫と稲作の殻は十分に利用されていません. 木炭練炭の生産ラインが開発されている場合, これらのリソースを利用して、高い経済的価値を生み出すことができます. また、収入を増やし、同時にリソースを節約することもできます. このために, 木炭練炭の生産のための人気のある計画の1つは、炭押しシステムです. よりシンプルなプロセスと低い投資. 数日前, ベトナムの顧客は、 炭briquette植物.

ベトナムの顧客が木炭押出システムを購入する理由?

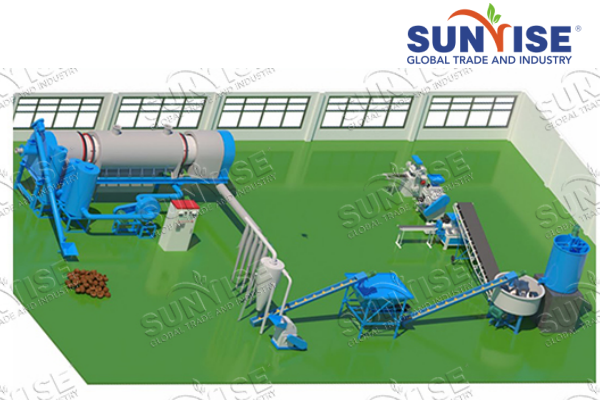

顧客は独自の炭化システムを持っています. しかし, 今、ベトナムのクライアントはシステムをに拡張する計画を立てています 木炭練炭の生産 より多くの利益を上げるために. 一般的に, がある 2 たくさんの木炭が1時間に発生しました, and the moisture 5%. The customer wanted to start from a simple and low investment process. それで, we recommended the charcoal extruding line to him.

Operational efficiency feedback of the charcoal extruding line

As for char-molder, the client from India required a capacity of 500-800 kg/h. In order to meet customer's requirements, we recommend you charcoal rotary tablet press and hookah press machine.

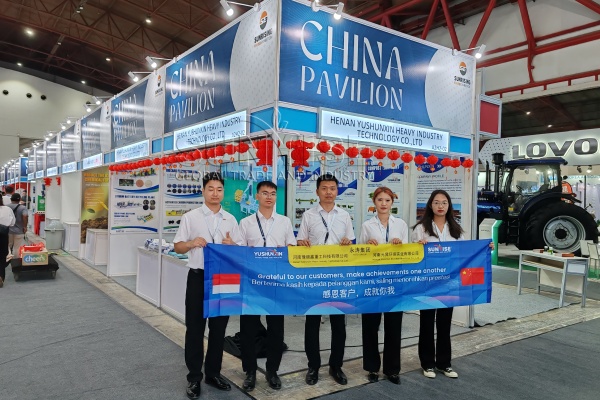

Before deciding the charcoal extruding plan, the Vietnamese guest flied to China to visit our biochar briquette machines. In the tour, from the first run, the charcoal extruding system impressed the customer with its efficiency. With simple process, the charcoal extruding line can quickly produce triangle, ラウンド, 四角, 矩形, plum blossom, etc charcoal briquettes from agricultural waste charcoal. It only need material feeder, チャコールホイールグラインダー, double shafts mixer, 木炭押出機 そして automatic packing machine.

"Now, the effective charcoal extruding line had in my factory. It can dispose of agricultural waste charcoal into biochar briquettes fast as seen in your factory." The client praised.

Considerate guidance of biochar briquette extruding plant installation

Another point of surprise for Vietnamese customer is fast charcoal briquette equipment installation. After receiving the machines for charcoal briquette making, the installation took just under a week. 一つに, the combination of charcoal extruding line is relatively straightforward. It only needs to put the equipment to corresponding place, there is nearly no parts assembly. 別のために, with the charcoal extruder equipment arriving well-packaged, complete with instructional manuals. 加えて, SUNRISE also can offer you remote or field guidance on installation, operation, etc according to your needs.

How about the ROI of forming agricultural waste charcoal with biochar extruding system?

一般的に, the investment in a 2 t/h charcoal extruding system is $75,000-$170,000. しかし, after making agricultural waste charcoal into briquettes, the can be doubled. したがって, only takes one or even half a year, you can earn back the money spent on the charcoal extruder machines. 一般的に, as long as you replace the extruding mold once a year or half a year, this production line can produce agricultural waste charcoal briquettes for you for more than 10 years. The main body adopts Q235 carbon steel and the extruding molds use SUS304 stainless steel as material.

Besides the charcoal extruding line to Vietnam, we also offer many other types of charcoal briquette plants to all over world. のような 500-800 kg/h sawdust charcoal briquette making plan, 10 t/h biochar briquette machines, 等: to Kenya, Brazil, インド, Ghana, 等. If you plan to start a charcoal briquette plant, welcome to contact us for your own charcoal briquette production solutions.