Rice husk is the protective coat around rice seeds. It is a waste material that is obtained in tons during the rice harvesting season. And the most abundant components present in rice husk are cellulose, lignin, and silica. Due to the high percentage of lignin (natural binding material) and low water content, rice husk is a valuable raw material to make charcoal briquettes for household or industrial uses. Kanggo iki, on 15th June 2024, a customer from Japan wanted to purchase a set of rice husk charcoal briquette machine. Ing ngisor iki minangka rincian komunikasi khusus ing kasus iki:

Ndhuwur 2 rice husk charcoal briquette making method

Pelanggan Jepang iki pengin ngerti cara nggawe briquet biokar. Umumé, Ana Loro Cara Nggawe Briquette Arang saka husk beras. Siji-sijine kasebut langsung karbonisasi beras dadi areng liwat tungku karbonisasi, banjur compressing areng penius dadi briquette. Liyane yaiku nyompres pari dadi Briquette dhisik dening Mesin Briquette Rice Husk, banjur karbonisasi briquette husk rame dadi arang.

Carbonization first & then forming

This method is suitable for customers with sufficient budget. Because rice husks are very small and the only carbonizer suitable for this feed size is a Tungku karbonisasi terus-terusan – 5-20 mm. Biasane, rice husk as a fine particle material does not need to be further crushed, you can feed it directly. Sawise iku, you can use charcoal wheel grinder to make charcoal powder. Pungkasane, there are four Chargo Briqual Makeces for your choice to produce rice husk biochar briquettes.

Mbentuk pisanan & banjur karbonisasi

The Konten kelembapan ing husk rame nganti tekan 15%. Nanging, Disaranake materi mentah kudu 8% menyang 10% Kelembapan ing. Dadi sampeyan butuh pengering kanggo nyuda isi kelembapan. Lan kanggo nyuda biaya briquetting husk, Sampeyan uga bisa diselehake ing srengenge kanggo nyuda isi kelembapan liwat penguapan. Wiwit husik kaya cilik, Dadi ora butuh kanggo ngremehake. Sawise pangatusan, sampeyan bisa langsung menehi feed menyang Mesin Ekstruder Areng. Pungkasane, liwat nggunakake Mesin karbonisasi heisting utawa tungku jenis karbonisasi jinis, Sampeyan bisa Entuk Briquette Biokit Ramah.

What is the price of rice husk charcoal briquette plant?

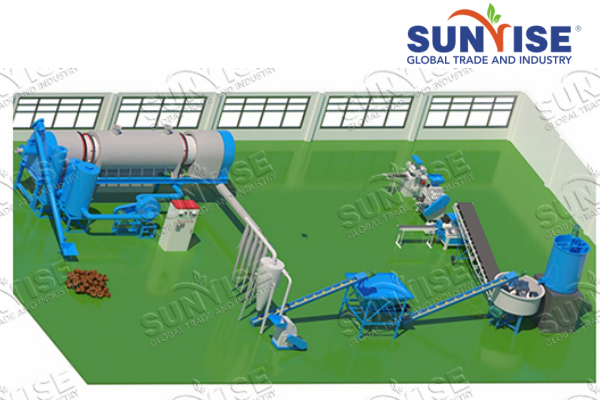

Then the customer from Japan also wanted to know the price of rice husk biochar briquette plant. And the cost of rice husk charcoal briquette production usually varies according to capacity, equipment configuration and many other factors. Here we will show you the prices of 500-1000 kg/h small scale rice husk charcoal briquette production line, 1-10 t/h rice husk biochar briquette making line and 10-30 t/h large scale rice husk charcoal briquette manufacturing system for your reference.

500-1000 kg / h

- 600-1050㎡

- (Reference)

1-10 t / h

- 1250-3000㎡

- (Reference)

10-30 t / h

- 3000-4000㎡

- (Reference)

Is there a lower investment rice husk charcoal briquette making plan?

Mesthi wae. The above is the price of the highest configuration business plan machines. Kajaba iku, we can offer you two basic designs. Umpamane, for one basic carbonization furnace + gilingan rodha rodha + charcoal briquette maker, sampeyan mung kudu nyiyapake $5,000-$23,000 (carbonization first & then forming method). As for another design, with charcoal extruder + hoisting or batch type carbonization furnace (forming first & then carbonization method). Babagan $ 8,000-$23,000.

What is the use of rice husk charcoal briquette from Sunrise machine produced?

Pungkasane, Japanese client prepare to get more profits from these rice husk biochar briquettes. So he asked us the use of rice husk charcoal briquette. In addition to being used as fuel, rice husk charcoal briquette is also widely used in industry and agriculture.

Rice husk charcoal briquette production line is an ideal choice for beginners production. But if you want to produce small scale rice husk biochar briquette, you can choose our small scale rice husk charcoal briquette production plan.