Is there a business plan for large scale biochar briquette manufacturing. Mesthi wae. We can provide you with 300,000 t/y charcoal forming project. And in terms of hourly output, it can reach 10 t / h. So it can fully meet your requirement of commercial charcoal briquette making in large quantities. Kajaba iku, according to the needs of different charcoal briquette manufacturers, we especially design various 300,000 t/y charcoal briquette preparation systems. Kayata 300,000 t/y charcoal production system, 300,000 t/y biochar briquette line, 300,000 t/y charcoal briquette packaging system, lsp. If you have any other requirements, you can contact us immediately, kita bakal menehi sampeyan solusi nggawe briket biochar paling apik.

Carane miwiti 10 t/h proyek nggawe briket biochar?

Yen sampeyan pengin nguripake biomassa bahan (Rice Husk, pring, sawdust, lsp) dadi briket areng ing skala gedhe, sampeyan bisa milih kita 10 t / h proyek produksi biochar. Ing proses iki, sampeyan kudu telung langkah:

Ngremuk bahan biomas dadi bubuk alus

Ing kene, ngremukake materi biomas dadi wêdakakêna alus iku pilihan becik kanggo nggampangake pangatusan materi. Amarga ukuran partikel luwih cilik, luwih gedhe area kontak karo pangatusan. Banjur amarga saka kapasitas gedhe saka 10 t / h, Disaranake sampeyan milih YS-800 palu pabrik. Ora mung nduweni output gedhe nanging uga bisa nggiling akeh bahan biomas dadi bubuk sing apik tanpa maneh.

Nyetel isi kelembapan

Umumé, kandungan Kelembapan bahan mentah nduweni peran penting ing nggawe briket areng. Because moisture can affect the bonding between raw materials. Too much moisture may cause the raw materials to become too wet, reducing their bonding ability and making the charcoal briquette not strong enough. Mula, it is advisable to adjust the moisture to 5%-15% before biochar briquette production. And using YS large scale rotary dryer machine is a more effective method. Nanging yen materi sampeyan sawdust, we can also provide you with Pengering Alur Air which is more suitable for drying smaller pieces.

Using continuous carbonization furnace

Apa maneh, you need to purchase a suitable carbonization machine. For large scale biochar making, Tungku karbonisasi terus-terusan is the best option. Kanggo siji bab, its capacity is 1000 kg/h with continuous production, which is far more than other carbonization machines. So it can help you finish 300,000 t/y biochar briquette production project quickly. Kanggo liyane, this equipment adopts a fully automated electrical control system. During the working process, even without any operation, it can turn biomass material into biochar.

Tips: Yen sampeyan nggunakake mesin iki kanggo ngasilake areng, Kita saranake ukuran bahan sing ora luwih gedhe tinimbang 50mm. Sanajan Rotes karbonisasi karn duwe fungsi pangatusan, Kita ora saranake karbonisasi bahan teles langsung, Bakal mengaruhi efisiensi karbonisasi lan kualitas arang. Dadi luwih becik manawa nggawe kelembapan bahan kurang 30%. So you need to process biomass materials in advance.

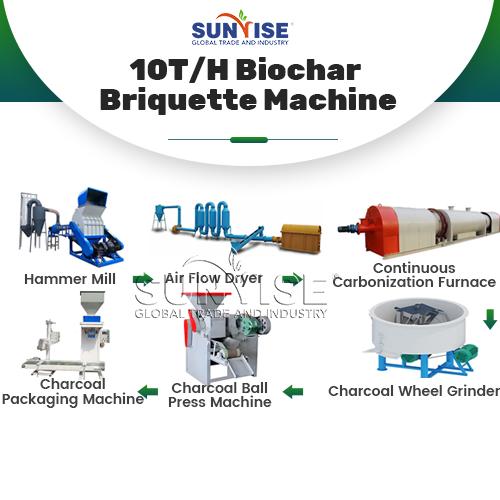

What equipment is used in large scale biochar briquette production?

Is there charcoal briquette making plan for further process biochar? Wangsulane ya. If you have completed the biochar, you can purchase 300,000 t/y charcoal briquette line directly. During 300,000 t/y charcoal briquette making, you may need equipment: Mesin Press Bola Areng, gilingan rodha rodha.

10T/H packaging system for your finished biochar briquettes processing

When you have finished biochar briquette making and want to sell to your customers, it is advisable to use our packaging system for large scale charcoal briquette manufacturing. Because in this system,

Automatic charcoal bagging equipment can help you package finished charcoal briquettes into 10 kg / tas, 15 kg / tas, 30 kg / tas, 50 kg/bag and 65 kg / tas, lsp. So you can sell charcoal briquettes to your customers in a targeted way. For capacity of 300,000 tons per year, YS especially design round hookah charcoal packing machine, cube shisha biochar packing machine, BBQ charcoal packing machine and honeycomb briquette bagging equipment for your choice.

And there are some other machines equipped with round hookah charcoal packing machine. Hookah charcoal dispenser and heat shrink packaging machine. Hookah charcoal dispenser’s tracks allow the individual products to be separated. And heat shrink packaging machine can add plastic film to the outside of the product can prevent the box from scratching and also prevent moisture. So they can both help you package charcoal briquettes. You can choose them according to your budget.

How much does the large scale biochar briquette making machine cost?