In recent years, Vietnam’s agricultural development is in good condition. 매년, a large amount of crop straw and rice husks are not fully utilized. If a charcoal briquette production line is developed, these resources can be utilized and generate high economic value. It can also increase income and save resources at the same time. 이것을 위해, one popular plan for charcoal briquette production is charcoal extruding system. Simpler process and lower investment. Several days ago, a Vietnamese customer provided invaluable feedback on the operational efficacy of the 숯불 공장.

Why the Vietnamese customer buy the charcoal extruding system?

The customers have own carbonization system. 하지만, now the Vietnamese client plan to expand the system to 숯불 연탄 생산 to make more profits. 일반적으로, 거기 있습니다 2 tons of charcoal generated an hour, and the moisture 5%. The customer wanted to start from a simple and low investment process. 그래서, we recommended the charcoal extruding line to him.

Operational efficiency feedback of the charcoal extruding line

As for char-molder, the client from India required a capacity of 500-800 kg/h. In order to meet customer’s requirements, we recommend you charcoal rotary tablet press and hookah press machine.

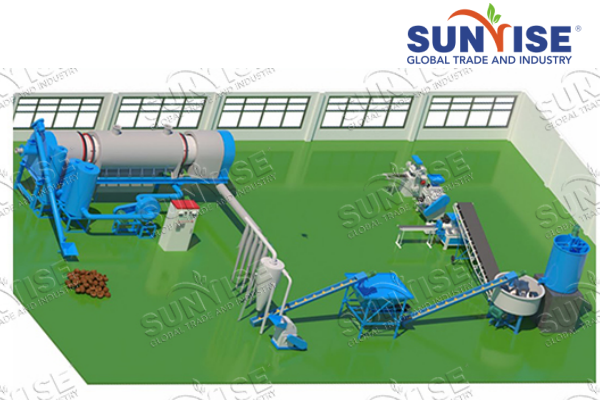

Before deciding the charcoal extruding plan, the Vietnamese guest flied to China to visit our biochar briquette machines. In the tour, from the first run, the charcoal extruding system impressed the customer with its efficiency. With simple process, the charcoal extruding line can quickly produce triangle, 둥근, 정사각형, 구형, 매실 꽃, etc charcoal briquettes from agricultural waste 숯. It only need material feeder, 숯 휠 그라인더, 이중 샤프트 믹서, 숯 압출기 기계 그리고 automatic packing machine.

“Now, the effective charcoal extruding line had in my factory. It can dispose of agricultural waste charcoal into biochar briquettes fast as seen in your factory.” The client praised.

Considerate guidance of biochar briquette extruding plant installation

Another point of surprise for Vietnamese customer is fast charcoal briquette equipment installation. After receiving the machines for charcoal briquette making, the installation took just under a week. 우선, the combination of charcoal extruding line is relatively straightforward. It only needs to put the equipment to corresponding place, there is nearly no parts assembly. 다른 사람을 위해, with the charcoal extruder equipment arriving well-packaged, complete with instructional manuals. 게다가, 해돋이 also can offer you remote or field guidance on installation, operation, 당신의 필요에 따라 등.

How about the ROI of forming agricultural waste charcoal with biochar extruding system?

일반적으로, the investment in a 2 t/h charcoal extruding system is $75,000-$170,000. 하지만, after making agricultural waste charcoal into briquettes, the can be doubled. 그러므로, only takes one or even half a year, you can earn back the money spent on the charcoal extruder machines. 일반적으로, as long as you replace the extruding mold once a year or half a year, this production line can produce agricultural waste charcoal briquettes for you for more than 10 연령. The main body adopts Q235 carbon steel and the extruding molds use SUS304 stainless steel as material.

Besides the charcoal extruding line to Vietnam, we also offer many other types of charcoal briquette plants to all over world. 와 같은 500-800 kg/h sawdust charcoal briquette making plan, 10 t/h biochar briquette machines, 등: to Kenya, Brazil, 인도, Ghana, 등. If you plan to start a charcoal briquette plant, welcome to contact us for your own charcoal briquette production solutions.