On 10th June, 2025, a customer from Kenya inquired about how to make charcoal briquettes from biomass waste. “My raw materials are corn cob, 목재, wood shavings, spent brew, 사탕수수, I want the capacity of 2 시간당 톤. The budget is only $150,000, so I need the precise quote for the charcoal briquette machine price.” 마지막으로, the Kenyan customer chose to buy a charcoal extruder line. 다음은이 사례의 특정 세부 사항입니다:

Can the machine make biomass waste into charcoal briquettes?

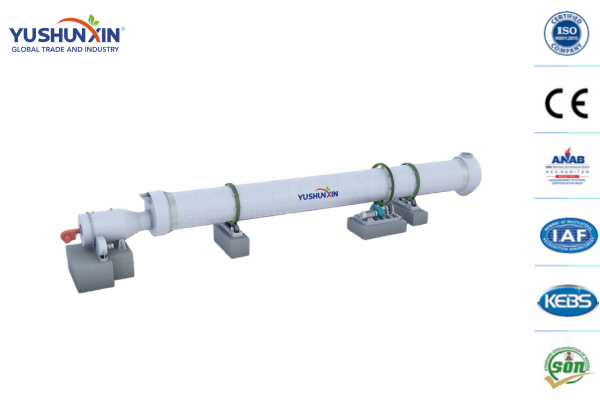

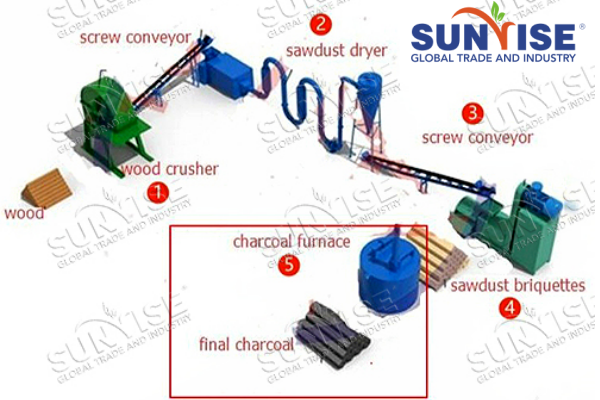

The Kenyan customer planned to make charcoal briquettes from biomass waste. Contains corn cob, 목재, wood shavings, spent brew, 사탕수수, 등. For charcoal briquettes manufacturing, you need to turn the biomass waste into small pieces first. As a reliable charcoal briquettes machine manufacturer, 유 룬신 also has professional biochar briquette machines for you. 이것을 위해, we recommend you with hammer mill. And if your materials have more 수분, drying machine is necessary. So you can choose rotary dryer and airflow dryer, which can reduce moisture to 8-12%.

Is there 2 t/h charcoal briquette machine?

에 관해서는 숯불 연탄 기계, the client from Kenya required a capacity of 2 시간당 톤. To produce charcoal briquettes for 2 shifts workers a day and 10 hours a shift, we recommend you buy charcoal extruder and roller type press machine.

Economical charcoal extruder for biochar briquette making

에이 숯 압출기 기계 is ideal for medium-scale charcoal briquette production. Especially 1-10t/h output. 우선, this equipment comes with a cutting device that allows you to adjust the speed to cut the charcoal briquettes into the required length. 다른 사람을 위해, you can change molds according to your requirements. Such as hollow, solid, hexagonal, 정사각형, and honeycomb shapes.

Charcoal ball press machine for large scale biochar briquettes operations

For 2t/h charcoal briquette machine, another choice is 숯 볼 프레스 머신. It is the best choice for ball type charcoal making. It employs a pair of high-strength alloy steel pressure rollers with evenly distributed ball-and-socket surfaces. And this results in high charcoal forming density and consistent dimensions. 뿐만 아니라, the roller skin is made of a wear-resistant alloy material, with a service life of 800-1200 시간.

게다가, to improve the final charcoal briquettes quality, it is advisable to buy a 2t/h charcoal briquette production line. Which consist of hammer mill, 회전식 건조기, 연속 탄화 기계, 숯 휠 그라인더, char-molder and charcoal packaging machine.

How much does the 2t/h charcoal briquette machine price price? Is $150,000 enough?

그 다음에, the customer paid attention to the 숯화 용기 기계 가격. 일반적으로, the quote of a complete 2 TPH charcoal briquette making line with rotary drum dryer and charcoal ball press machine is $160,000-$300,000. If you need a $150,000 cost charcoal briquette machines layout with 2t/h capacity. 거기 있습니다 2 tips for you.

마지막으로, the customer from Kenya adopt our tips. The partial main parameter of 2t/h charcoal briquette machine price (only for reference) is as follows:

| 장비 | 용량 | 가격 | Quality |

| 해머 밀 | 0.5 - 4 TPH | $1,000 - $6,000 | 1 |

| Airflow dryer | 0.5 - 5 TPH | $5,000 - $30,000 | 1 |

| Continuous carbonization machine | 1 - 3 TPH | $8,000 - $60,000 | 1 |

| 숯 휠 그라인더 | 0.5 - 3 TPH | $1,000 - $6,000 | 1 |

| 숯 압출기 기계 | 1 - 10 TPH | $2,000 - $8,000 | 1 |

| 숯 포장 기계 | 0.5 - 2 TPH | $2,000 - $15,000 | 1 |

How long can we receive the charcoal briquette machines when to Kenya?

Charcoal briquette machines from YUSHUNXIN to Kenya usually needs 30-45 날. 왜냐하면, sometimes we need 5-10 days to manufacture equipment for charcoal briquettes production, when the equipment is not in stock. 괜찮아요, we will help you receive the biochar briquette equipment and start charcoal briquettes making as soon as possible. 이것을 위해, we receive DDP payment.

The above are details about our communication with the Kenyan client about the 2t/h charcoal briquette machine price. If you need the precise quote for your charcoal briquette production line, welcome to contact us now!