On 5th October, 2024, a customer from India inquired about how to make charcoal briquette from sawdust. “My raw materials are fresh sawdust through processing waste wood, l want the capacity of 5-8 tons per day. The budget is only $100,000, so l need the precise quote for the sawdust charcoal briquette molder price.” 마지막으로, the Indian customer chose to buy a 500-800 kg/h biochar briquette making line. 다음은이 사례의 특정 세부 사항입니다:

Can the machine make fresh sawdust into biochar briquette?

This Japanese customer wanted to know the method of making rice husk biochar briquette. 일반적으로, 거기 있습니다 two ways of making charcoal briquette from rice husk. The one is directly carbonizing rice husk into charcoal through a carbonization furnace, and then compressing the rice husk charcoal into briquettes. The other is to compress rice husk into briquettes first by the rice husk briquette machine, then carbonize the rice husk briquettes into charcoal.

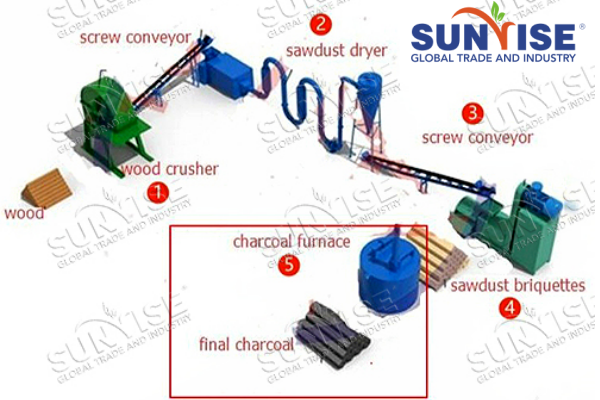

The Indian customer planned to make charcoal briquette from processing waste wood. For charcoal briquette making, you need to process waste wood into sawdust first. Then you can make sawdust into charcoal. As a reliable charcoal briquette machine manufacturer, SUNRISE also has professional carbonization furnaces for you. 포함 economical hoisting carbonization furnace, easy operation 배치 타입 탄화 기계 그리고 large continuous carbonization machine.

Forming first & then carbonization

그만큼 수분 함량 in the rice husk is up to 15%. 하지만, it is suggested that the raw material should have 8% 에게 10% moisture in it. So you need a dryer to reduce the moisture content. And to reduce the cost of rice husk briquetting, it can also be placed under the sunlight to decrease moisture content through evaporation. Since rice husk is small in size, so there no needs for crushing. After drying, you can directly feed it into 숯 압출기 기계. 마지막으로, through using 호이 스팅 탄화 기계 or batch type carbonization furnace, you can get rice husk biochar briquette.

Is there 500-800 kg/h char-molder for sawdust biochar briquette making?

As for char-molder, the client from India required a capacity of 500-800 kg/h. In order to meet customer’s requirements, we recommend you charcoal rotary tablet press and hookah press machine.

Charcoal rotary tablet press for biochar tablets making

에이 숯 회전 정제 프레스 is ideal for small-scale charcoal briquette operations. Especially lower than 1 TPH output. 우선, high speed rotary design make it accommodate a small amount sawdust while ensuring quickly charcoal tablets making. And you can also adjust the rotary speed. 다른 사람을 위해, this machine is made of 스테인레스 스틸 material. 게다가, the surface of the turntable undergoes special treatment to maintain gloss and prevent cross-contamination, in compliance with GMP requirements.

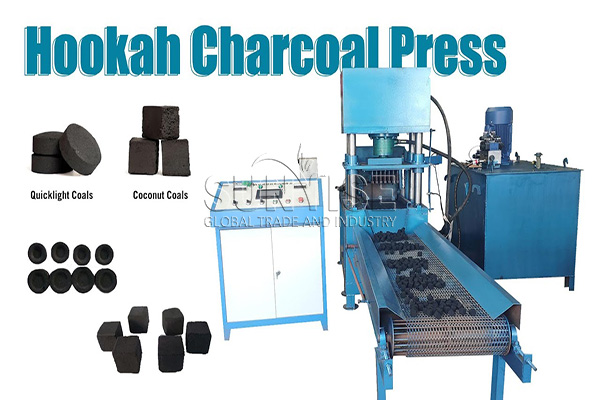

Hookah press machine for round&cube charcoal briquette production

을 위한 500-800 kg/h char-molder, another choice is 물 담뱃대 프레스 머신. For hookah press machine, we can provide you with two types: mechanical shisha biochar maker and hydraulic shisha charcoal briquette machine. They can both produce cube or round charcoal briquettes. And they usually feature an adjustable pressure control system to meet the requirements of different formulations, ensuring consistency and quality in charcoal briquette compression.

게다가, to improve final charcoal briquette quality, 구입하는 것이 좋습니다 500-800 kg/h complete sawdust charcoal briquette line. Which consist of 해머 밀, air flow dryer, 연속 탄화 기계, 숯 휠 그라인더, char-molder and packing equipment.

How much does the 500-800 kg/h biochar maker price? Is $100,000 enough?

그 다음에, the customer paid attention to the sawdust charcoal briquette price. 일반적으로, the quote of a complete 500-800 kg/h sawdust charcoal briquette production line with continuous carbonization machine and hookah press machine/ charcoal tablet press is $110,000-$150,000. If you need a $100,000 cost sawdust charcoal briquette machines layout with 500-800 kg/h capacity, you can choose hoisting carbonization machine or batch type carbonization machine. They only need $5,000-$7,500. But if you choose them to make sawdust charcoal briquette, it is necessary to change charcoal briquette maker. Because hoisting carbonization machine and batch type carbonization machine are suitable for columnar materials. 이것을 위해, you need to use charcoal extruder to compress sawdust into columnar materials firstly (Only 숯 압출기 meet this requirement). Then carbonizing them through hoisting and 배치 타입 탄화 기계. And charcoal extruder machine only need $3,000.

How long we can receive the sawdust charcoal briquette maker when to India?

Sawdust charcoal briquette making machines from 해돋이 to India usually needs 30-45 날. 왜냐하면, sometimes we need 5-10 days to manufacture equipment for sawdust biochar briquette production, when the equipment is not in stock. 괜찮아요, we will help you receive the 숯화 용기 장비 and start sawdust biochar briquette making as soon as possible. 이것을 위해, we receive DDP payment.

The above are details about our communication with the Indian customer about 500-800 kg/h sawdust charcoal briquette machine price. If you need the precise quote for your 숯불 연탄 생산 라인, welcome to contact us now!