Charcoal briquette making machine refers to the equipment for compressing charcoal powder into different shape blocks. According to the different briquetting principles and briquette shapes, we divide them into 3 Nga momo momo. Miihini Miihini Utu, biochar ball press equipment and hookah press machine. Then in order to produce high quality biochar briquette, it is necessary to buy a suitable charcoal briquette machine.

NO.1 Hookah press machine for small scale shisha charcoal briquette making

Mō making hookah biochar briquette in a small scale, most charcoal briquette manufacturers choose our hookah press equipment. He aha ai? E toru nga take:

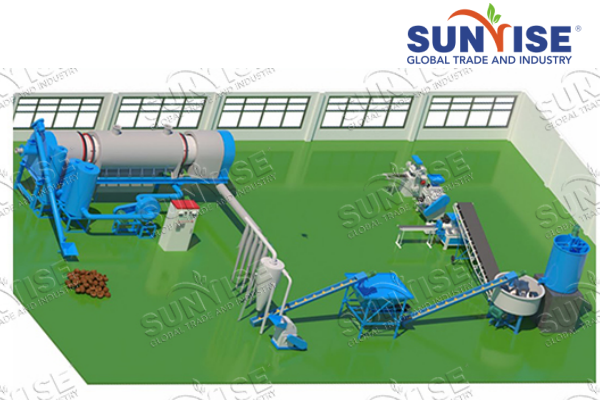

NO.2 Biochar ball press machine for industrial charcoal briquettes production

But for large scale charcoal briquette making, the most popular equipment is miihini poihau poihau. He aha ai? What are the benefits of biochar ball briquette making equipment?

Finishing large scale biochar briquette making quickly

Compared with hookah press machine, charcoal ball press equipment can complete large scale biochar briquette production more quickly. Na te mea he nui te kaha, which is high to 45 t / h. No reira, within the same time, biochar ball press equipment can make 2-5 times as many briquettes as other charcoal briquette making machines.

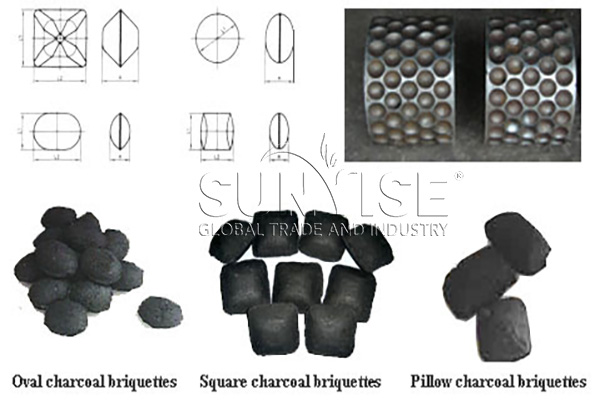

Making different shapes of biochar briquettes

It can convert charcoal powder into oval shape and pillow shape briquettes through using two rollers extrusion. He aha ake, the materials of rollers are divided into 65 koporese, 9 numoana 2 molybdenum, high chromium alloy, Na pera i runga. And you can customize rollers according to your needs. Mo tenei, the final product is convenient for storage and transportation.

NO.3 Charcoal extruder machine for low cost biochar briquette making

Then from the feedback of our customers, we find that there are also a large amount of businesses prefer to buy rod biochar extruder. Because it can turn charcoal powder into briquettes at a lower cost.

Reducing the cost of buying charcoal briquette machine

Te charcoal briquette extruder machine adopts spiral extrusion molding. So it is generally simpler and more straightforward than other biochar forming equipment, which reduces manufacturing costs. And this machine can make 1-10 t/h charcoal briquette. Then unit costs may be lower due to economies of scale. Nō reira, e hiahia ana koe anake $5,000-$20,000 to get this machine.

Purchasing biochar extruder equipment from source factory

Me Ys can provide you with charcoal rod extruder at a favourable price. Because we are a source factory, which has no extra cost to purchase this machine. Tīmata, we have more than 20 experiences for manufacturing char-molder.

The above is the top 3 charcoal briquette making machines in 2024. I te taha, YS can also provide you with many other biochar briquette machines. Hei tauira, mihini miihana waro, biochar packaging equipment, take. Mena kei te pirangi koe ki a raatau, tēnā whakapā mai. We will provide you with high quality charcoal processing machines at an ideal price!