When you want to choose a suitable charcoal briquette maker, you need to know their designs for making high quality briquettes. In YS, we can offer you with 3 types of biochar briquette making machines, which have respective designs. The following are the detailed information:

NO.1 Rod charcoal molding equipment

If you select to make charcoal briquettes, you need to understand that what designs can make high quality biochar pellets.

The size and moisture of feeding materials

The ideal feeding materials size is less than 3 mm. If your materials is too large, you can use grinder to dispose of materials. Me 10-14% is best moisture for briquette making on charcoal briquette extruder. Me te makuku iti, Ko te raru ka nui te mea ka puta ake te putanga Briquette, the briquette with high moisture will be softer and takes more time to dry.

Te kaha me te kaha

Extrusion briquette maker is a kind of screw briquette machine makes high pressure than other briquette machine. And the common pressure of charcoal briquette extruder is 35 Mai. Then the material will stay much longer in briquette extruder (Ko te tere o te putanga mo te briquette te tikanga 20-40 mm / s ) na te mea e hangahia ai te kaihopu briquette.

NO.2 Charcoal ball press machine

When you want to make ball, pillow, square and lath biochar briquettes, you can choose this biochar briquette maker. But what is the design of Roller Press Press miihini?

Adjustable ball size

What is the size of final ball produced by roller charcoal briquette press equipment? This is an item most briquette manufacturers focus on. I roto i te katoa, our biochar ball press machine can prepare briquettes with a diameter of 25-50mm. This can fully meet your needs.

Suitable materials size and moisture content

If you want to make high quality charcoal ball, suitable material is essential. I ngā wā katoa, the size of material is below 5 mm. And the moisture content is between 7-15%. Then when you prepare to add some binders in the process of charcoal ball pressing, the moisture will be different.

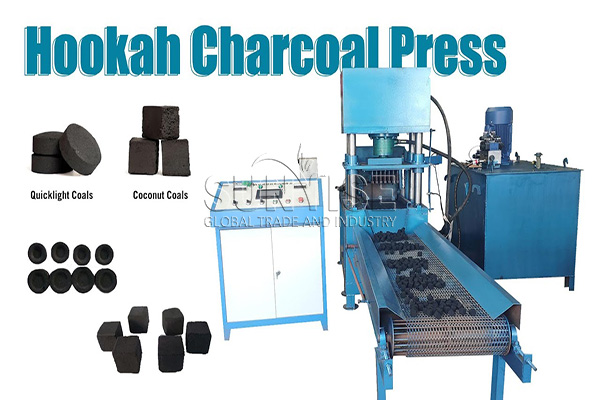

NO.3 Hookah press equipment

Because this machine mainly produce shisha biochar briquettes, so we design this machine according to the final product.

Various molding for your choice

The shisha charcoal briquettes’ shapes can be cubic, diamond, ringlike, rhomboid, triangular form, cylinder, pyramid, convexity, concavity, round tablets, take. So we design types of molds for your choice. And we can also provide you with customization service according to your needs. The final product diameters are about 30-40 mm with round shape and 20-25 mm with cube shape.

Mechanical and hydraulic types

There are two types of hookah press machines Mo taau whiriwhiri. Mechanical and hydraulic type. They can use different pressures to make high quality hookah charcoal briquettes. You can choose them according to your requirements.