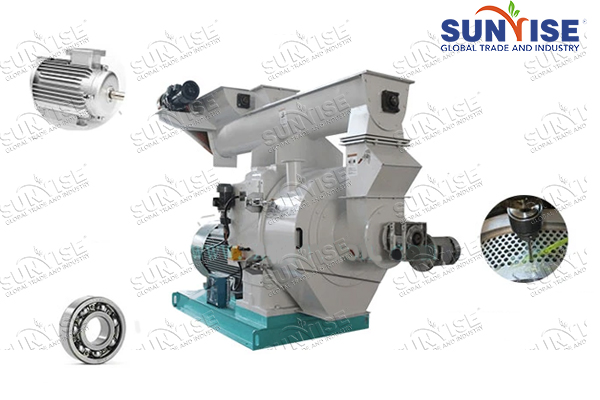

Ring die pellet mill is the key component in a complete biomass pellet plant. It is mostly used to process wood materials like wood chips, Serratura, tree branches, logs, U l-bqija. Also, it can process other raw materials like palm fiber, Bagasse tal-kannamieli, peanut shell, corn stalk, wheat straw, charcoal powder and many other agro-wastes. After Sunrise has analyzed the cost and profit of the biomass pellet processing industry and the ring die pellet machine. And it can be understood that the investment in the ring die pellet machine is very promising and there is also a profit margin. Fl-istess ħin, on 16th May 2024, a customer from Vietnam wanted to buy a ring die biomass pellet machine. So he wanted to know the detailed information about it. The following are the specific details of our communication in this case:

What type of ring die biomass pellet machine is suitable for you?

This Vietnamese client wanted to buy a suitable ring die pellet mill. But he didn’t know how to select a suitable one. B'mod ġenerali, there are two types of ring die pellet machines for your choice.

Small ring die pellet machine

This type of machine usually can produce 500-800 kg / h bijomassa pellets. And it is a vertical type, which both has the roller and ring die rotate. Għal dan, they can form centrifugal force and distribute raw material uniformly.

Large ring die pellet mill

When you prepare to produce 1.2-2.5 t/h biomass granules, this large ring die pellet mill is the best choice for you. And it is more suitable for industrial pellet production. Barra minn hekk, this large ring die pelletizing machine have larger density and is much smoother surface due to its higher pressure.

How much does the biomass pellet plant cost?

Imbagħad, this customer from Vietnam asked about the price of this biomass pellet plant. B'mod ġenerali, the final quote of this production line is closed related to capacity, Numru tat-tagħmir, machine type and model, eċċ. Because of the small capacity and simple granulation process, it is enough to prepare $35,000-$160,000 for this biomass pellet plant. The final investment depends on the details granulator type and are there other auxiliary machines, accessories or not.

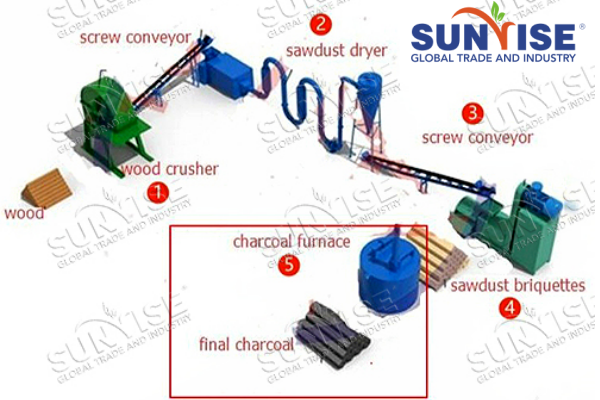

Considering the budget for biomass pellet making, the final plan of the Vietnamese customer is a simple biomass pellet line including Mitħna tal-martell, horizontal mixer, small ring die pellet machine, lifting machine and packaging equipment. And after one month, receiving the system, this client gave us a good feedback of these machines. And he had started biomass granule making smoothly.

Why do you choose Sunrise ring die pellet machine as a partner?

Fl-aħħarnett, this Vietnamese customer wanted to know what service can we provide for him. Għal dan, service represents the sincerity of the machine manufacturer. So why this customer choose us?

Sunrise is the leading Magna tal-Briquette tal-Faħam tal-Kannol manufacturer in China. Barra minn hekk, it has nearly 20 years of experience in the production of granlator and char-molder. So it can provide you with high quality equipment at the best price. Barra minn hekk, we can offer you the best service. Including free project design, featured customization machine and considerate after-sales service.