On 5th October, 2024, a customer from India inquired about how to make charcoal briquette from sawdust. “My raw materials are fresh sawdust through processing waste wood, l want the capacity of 5-8 tons per day. Bajeti yokha $100,000, so l need the precise quote for the sawdust charcoal briquette molder price.” Pomaliza, the Indian customer chose to buy a 500-800 KG / H biocher Briquete. Zotsatirazi ndi tsatanetsatane wa nkhaniyi:

Can the machine make fresh sawdust into biochar briquette?

Wogula waku Japanyu ankafuna kudziwa njira yopangira mankhusu a mpunga. Mwambiri, pali njira ziwiri zopangira briquette yamakala kuchokera ku mankhusu a mpunga. Yemweyo amathira mpweya mwachindunji mankhusu a mpunga kukhala makala kudzera mu ng'anjo ya carbonization, ndiyeno kufinya mankhusu a mpunga makala kukhala briquette. Wina ndikukanikizira mankhusu a mpunga kukhala ma briquette poyamba ndi makina a mankhusu a mpunga, Kenako sungani mankhusu a mpunga kukhala makala.

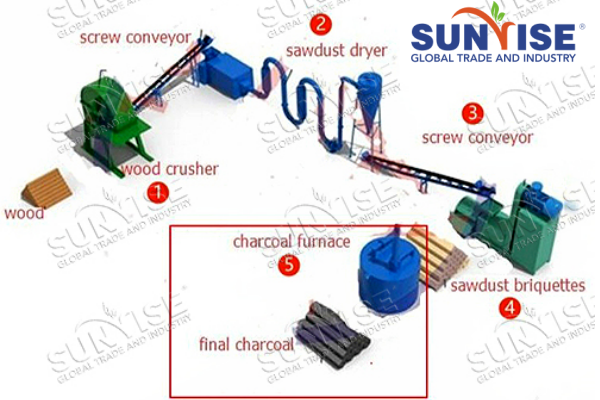

The Indian customer planned to make charcoal briquette from processing waste wood. For charcoal briquette making, you need to process waste wood into sawdust first. Then you can make sawdust into charcoal. As a reliable charcoal briquette machine manufacturer, SUNRISE also has professional carbonization furnaces for you. Including economical hoisting carbonization furnace, easy operation batch type carbonization machine ndi large continuous carbonization machine.

Kupanga koyamba & ndiye carbonization

A Zolemba mumpunga mankhusu mpaka 15%. Komabe, zimaganiziridwa kuti zopangira ziyenera kukhala nazo 8% ku 10% chinyezi mmenemo. Choncho mufunika chowumitsira kuti muchepetse chinyezi. Ndi kuchepetsa mtengo wa mankhusu a mpunga briquetting, imathanso kuikidwa pansi pa kuwala kwa dzuwa kuti ichepetse chinyezi kudzera mu nthunzi. Popeza mankhusu a mpunga ndi ochepa mu kukula, kotero palibe zofunika kuphwanya. Pambuyo kuyanika, mukhoza mwachindunji kudyetsa mu Makina a Makarcoal Exprider. Pomaliza, pogwiritsa ntchito Kunyamuka Makina a Carbotion kapena batch mtundu carbonization ng'anjo, mutha kupeza mankhusu a mpunga biochar briquette.

Apo 500-800 kg/h char-molder for sawdust biochar briquette making?

As for char-molder, the client from India required a capacity of 500-800 kg / h. In order to meet customer’s requirements, we recommend you charcoal rotary tablet press and hookah press machine.

Charcoal rotary tablet press for biochar tablets making

A makanda osindikizira makala is ideal for small-scale charcoal briquette operations. Especially lower than 1 TPH output. Pa chinthu chimodzi, high speed rotary design make it accommodate a small amount sawdust while ensuring quickly charcoal tablets making. And you can also adjust the rotary speed. Kwa wina, this machine is made of chitsulo chosapanga dzimbiri malaya. Kuphatikiza apo, the surface of the turntable undergoes special treatment to maintain gloss and prevent cross-contamination, in compliance with GMP requirements.

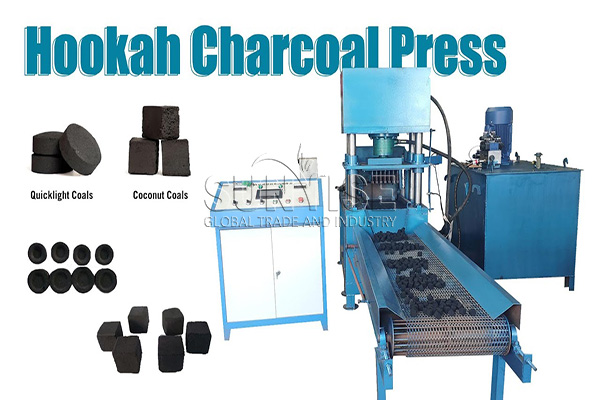

Hookah press machine for round&cube charcoal briquette production

Za 500-800 kg/h char-molder, kusankha kwina ndi Makina a Bookah Press. For hookah press machine, we can provide you with two types: mechanical shisha biochar maker and hydraulic shisha charcoal briquette machine. They can both produce cube or round charcoal briquettes. And they usually feature an adjustable pressure control system to meet the requirements of different formulations, ensuring consistency and quality in charcoal briquette compression.

Kuphatikiza apo, to improve final charcoal briquette quality, Ndikofunika kugula a 500-800 kg/h complete sawdust charcoal briquette line. Which consist of Bommer Mill, air flow dryer, Makina opitilira carbotion, Pulogalamu yamagalasi, char-molder and packing equipment.

How much does the 500-800 kg/h biochar maker price? Ndi $100,000 zokwanira?

Kenaka, the customer paid attention to the sawdust charcoal briquette price. Mwazonse, mawu athunthu 500-800 kg/h sawdust charcoal briquette production line with continuous carbonization machine and hookah press machine/ charcoal tablet press is $110,000-$150,000. Ngati mukufuna a $100,000 cost sawdust charcoal briquette machines layout with 500-800 kg/h capacity, you can choose hoisting carbonization machine or batch type carbonization machine. They only need $5,000-$7,500. But if you choose them to make sawdust charcoal briquette, it is necessary to change charcoal briquette maker. Because hoisting carbonization machine and batch type carbonization machine are suitable for columnar materials. Za ichi, you need to use charcoal extruder to compress sawdust into columnar materials firstly (Only makala otayira meet this requirement). Then carbonizing them through hoisting and batch type carbonization machine. And charcoal extruder machine only need $3,000.

How long we can receive the sawdust charcoal briquette maker when to India?

Sawdust charcoal briquette making machines from Kwacha to India usually needs 30-45 masiku. Chufukwa, nthawi zina timafunikira 5-10 days to manufacture equipment for sawdust biochar briquette production, pamene zida sizili m'gulu. Osadandaula, we will help you receive the charcoal briquette equipment and start sawdust biochar briquette making as soon as possible. Za ichi, timalandira malipiro a DDP.

The above are details about our communication with the Indian customer about 500-800 kg / h sawdust charcoal briquette machine price. If you need the precise quote for your Mzere wa Makarcoet Briquette, mwalandiridwa kuti mutilankhule tsopano!