On 25th July, a customer from Ghana inquired about buy Linha de produção de briqueta de carvão. We have a manufactury industry for charcoal briquette making. And we want to change our plant to producing more biochar briquettes. Production capacity of charcoal briquette 40 t per day. Depois, to email your quote of the equipment , its better.” According to the requirements, we finally sent him a 2 t/h charcoal extruding line at $100,000 custo. A seguir, são apresentados os detalhes específicos da comunicação neste caso:

What equipment is suitable for 40 t/d charcoal briquette plant?

The Brazil customer required an charcoal briquette plant with an output of 40 t per day. Então, for char-molder, we recommend you buy a YS-140 rod making equipment or a YS-290 charcoal ball press machine. The former has advantages of high extrusion rate (sobre 99%), small area occupation and economical price. The latter is a better choice for these who want to buy an biochar briquette machine with features of using 65 manganês steel casting as material which has a long wear life, low energy consumption and easy operation.

| Equipamento | Capacidade (T/H) | Poder(KW) | Dimension (mm) | Custo |

|---|---|---|---|---|

| YS-140 Charcoal Extruder Machine | 1-2 | 7.5 | 1950*1100*1180 | $1,700 |

| YS-290 Charcoal Ball Press Machine | 2-4 | 55 | 2260*1530*1980 | $3,500 |

Quanto o 40 t/d charcoal briquette making line cost? Is it within $100,000?

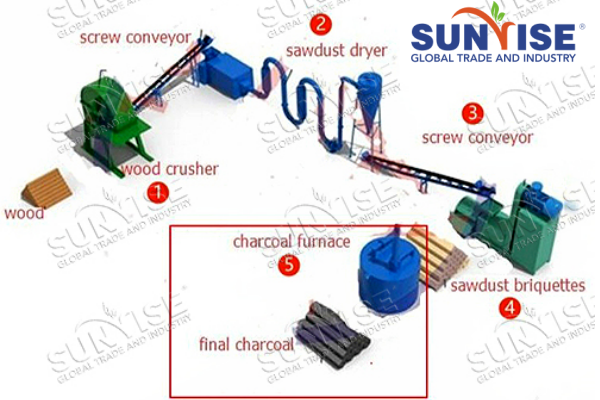

Geralmente, para $100,000 cost biochar briquette line, we recommend you buy a charcoal extruding system. Because the customer from Ghana have a manufacture industry charcoal briquette for carbonization. It usually consist of charcoal briquette machine as follows:

Geralmente, it consists of feeding machine→YS-112 charcoal wheel grinder→YS-0830 double shafts mixer→YS-140 charcoal extruder machine→YS-7*2m mesh belt dryer→YS-250charcoal packaging machine.

| Equipamento | Modelo | Capacidade (T/H) | Poder (KW) | Custo |

|---|---|---|---|---|

| Load Type Feeder | YS-2030 | 2-5 | 11 | $4,394 |

| Moedor de roda de carvão | YS-112 | 2-4 | 4 | $3,199 |

| Double Shafts Mixer | Ys-0830 | 2-5 | 22 | $6,500 |

| Máquina de extrusora de carvão | YS-140 | 1-2 | 7.5 | $1,700 |

| Mesh Belt Dryer | YS-7*2m | 56㎡(4 camadas) | 11 | $12,000 |

| Máquina de embalagem de carvão | YS-250 | 40-230 Bolsas/min | 2.6-3.4 | $3,600 |

How large an area required for the charcoal extruding line?

Além disso, the Ghanaians client asked about area required for the charcoal briquette production line. He want to know is it accommodated in a factory with 50 m length, 40 m width? A resposta é sim. Geralmente, the factory area of 200-250㎡is more suitable, which can be possible to accommodate and operate this line efficiently. Em geral, all the belt conveyor have 20 degree slop angle, the whole line height should be 20 m, the width and length is ok. Aqui, NASCER DO SOL will offer you customized biochar briquette making plan according to your factory area.

The above are details about our communication with the customer about how to buy charcoal briquette production line within $50,000 cost in Ghana. Além do mais, we can also offer you many biochar briquette making plans with other price. $100,000, $200,000 ou $500,000. Welcome to contact us for your customized charcoal briquette production business plan.