Waqtigii ugu dambeeyay, Joogitaanka dhuxusha dabiiciga ah waa yaraaneysaa. Laakiin baahida ay aad u sarreysay markii sahaydu xadidan tahay. Qayb ahaan sababta oo ah kaymaha yaraada iyo rabitaanka ah in la ilaaliyo geedaha. Natiijo ahaan, Mashiinka samaynta dhuxusha ayaa noqonaya maanta caan ah. Oo bilaabida ganacsiga dhuxusha dhuxusha waxay ahayd mashruuc faa'iido leh dalal badan, Sida Koonfur Afrika, Uganda, Kenya, iwm.. Tan, 19-kii Abriil 2024, Waxaan helnay macmiil ka sameysan sahlan dhuxusha xudunta Kenya. Macmiilkani wuxuu doonayey inuu ka dhigo dhuxul dhuxul laga sameeyo dhadday. Laakiin ma uusan garanaynin waxa uu yahay geedi socodka waxsoosaarka uu yahay. Waxyaabaha soo socdaa waa macluumaadka faahfaahsan ee kiiskan:

Why Is Sawdust Charcoal Briquette Making Popular in Kenya?

Kenya has long relied on traditional wood charcoal for cooking and heating, but with increasing deforestation and the rising cost of fuel, the search for alternative energy sources has become urgent. In recent years, producing charcoal briquettes from sawdust has gained popularity across the country. This eco-friendly solution not only reduces waste but also provides a sustainable source of income and energy for local communities.

Kenya’s furniture and timber industries generate large amounts of sawdust every day, most of which used to be burned or dumped. By converting this waste into charcoal briquettes, manufacturers can turn low-value residues into high-value fuel. This process helps reduce environmental pollution and promotes circular economy practices.

The Kenyan government encourages renewable energy initiatives and sustainable waste management. Projects that convert agricultural and wood waste into briquettes align with national clean energy goals and often receive support from NGOs and local authorities. This favorable policy environment makes sawdust charcoal production even more attractive to entrepreneurs.

With urban populations expanding and traditional charcoal prices increasing, demand for cheaper and cleaner fuel is growing rapidly. Sawdust charcoal briquettes burn longer, produce less smoke, and are more affordable for households, restaurants, and small industries-making them an ideal alternative in both rural and urban markets.

What Kind of Sawdust Is Used for Making Briquettes in Kenya?

Quality Requirements for Sawdust

The quality of sawdust has a direct impact on the strength, burning efficiency, and appearance of briquettes. Clean and uniform sawdust leads to higher carbonization efficiency and better compression during molding. The raw material should be free from paint, varnish, or chemical residues, as these can produce toxic gases during combustion. Finer particles are preferred because they fill molds evenly and bind more tightly under pressure. Choosing pure, uncontaminated sawdust ensures that the final briquettes are safe, odorless, and environmentally friendly.

How to Control the Moisture Content of Sawdust

Moisture control is one of the most critical factors in briquette production. The ideal moisture content of sawdust is between 8% iyo 12%. Haddii maaddadu aad u qoyan tahay, the briquettes will not hold their shape and will take longer to dry after pressing. Dhanka kale, overly dry sawdust lacks flexibility and reduces the bonding strength between particles.

To achieve the right balance, producers often dry sawdust under the sun or use a rotary drum dryer for faster and more consistent results. During rainy seasons, storing sawdust under a covered shed and using airflow dryers helps prevent moisture absorption. Regularly checking the material’s moisture level before carbonization or briquetting ensures stable production and high-quality briquettes.

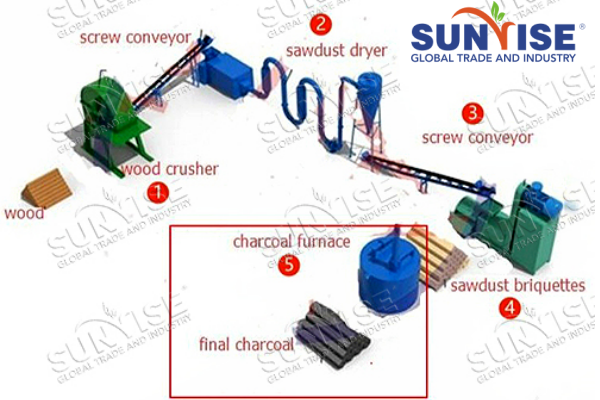

What is the Process of Making Biochar Briquette from Sawdust?

Macaamiishan reer Kenya ayaa rabay inuu ogaado Geedi socodka soosaarka dhaxalka xarkaha biochar. Guud ahaan, waxaa jira 4 Talaabooyinka soo saarista soosaarka dhuxul xudunta xun.

What is the Advantage of Making Sawdust Charcoal Briquette?

Ugu dhambayntii, Macaamiil ka socda Kenya ayaa diyaar u ah inuu sameeyo dhalay dhuxul dhuxul oo loogu talagalay waqti isku mid ah. Laakiin wuxuu ka walwalsanaa in faa iidada aysan u fiicneyn inay iibineyso dhuxul dabiici ah oo dabiici ah. Waxaan u sharaxnay faa'iidooyinka lagu maareeyo dhunkashada dhuxul.

How Much Does a Small&Large Scale Sawdust Charcoal Briquette Plant Cost?

Awooddu waxay door muhiim ah ka ciyaaraysaa kharashka dhirta culayska. Qiimaha mashiinka dhadday ee bayoolajiga ah ayaa ku kordhinaya awoodda. Macaamiishan Kenya waxay rabeen inaan siinno qorshe qiime.

How Much Does It Cost to Start a Sawdust Charcoal Briquette Business in Kenya?

Starting a charcoal briquette business in Kenya is one of the most promising clean energy investments today. With abundant sawdust from furniture and wood industries, and growing demand for eco-friendly fuels, our customer is turning this waste into profit. Hase yeeshee, before launching your briquette project, it’s crucial to understand the initial investment, machine cost, and expected returns.

What Are the Main Costs of Setting Up a Sawdust Charcoal Briquette Factory?

Establishing a sawdust charcoal briquette production line involves expenses for equipment, rakaabis, site preparation, labor, and electricity. The cost largely depends on your desired production capacity and automation level.

| Cost Category | Description | Estimated Cost Range |

| Installation & Commissioning | Machinery setup, test running and technician guidance | $2,000-$10,000 |

| Site Preparation | Factory building, foundation work, ventilation and layout design | $5,000-$30,000 |

| Labor Cost | Operators, technicians and management staff salaries | $2,000-$10,000/month |

| Electricity & Fuel | Power consumption for machines and heat source for drying and carbonization | $1,000-$5,000/month |

| Qalabka ceeriin | Dhalay, wood shavings, rice husk or other biomass feedstock | $500-$3,000/month |

| Transportation | Shipping of equipment and raw materials | $1,000-$8,000 |

| Maintenance & Spare Parts | Replacement parts, regular machine maintenance and lubricant | $1,000-$3,000/year |

| Miscellaneous | Licenses, taxes, safety equipment, office supplies, itc | $1,000-$5,000 |

What Factors Influence the Total Investment of Sawdust Charcoal Briquette Production?

Several factors affect your total startup cost beyond the machines themselves.

Dusha kore 3 Carbonization Machines for Sawdust Charcoal Briquettes Making

Ka dib markii laga wada hadlay hawsha, Macaamilka Kenya ayaa rabay inuu ogaado cunic-ka sinnace-ka si ay u badan tahay ku habboon soo saarida dhuxul safka ah.

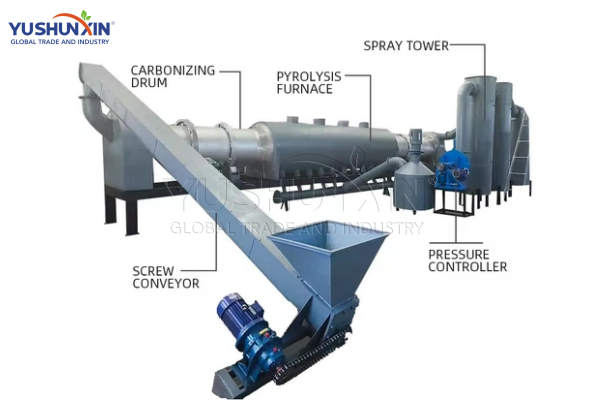

Mashiinka kaarboon-ka-qiijinta

-Ga / -da Ku ololeyda cuniceeceeyaha kaarboon Waxaa ku jira korantada korantada. Oo leh korantada korantada, Waxay kor u qaadi kartaa haanta gudaha, kaas oo badbaadinaya qiimaha shaqaalaha. Fooras walbana waa qalab la leeyahay 3 haamaha gudaha. Waqtigiisa kaarboonka waa 8-12 Saacadaha si loo hubiyo tayada wanaagsan ee dhuxusha. Ka dib hal taan oo agab ah ayaa dhammeeya kaarboon, Waxaad kor u qaadi kartaa kuwa-go'ay ka dibna waxaad dhigi kartaa haanta kale ee agab agab ah.

Deeraha kareemka sicir-bararka safka hore

Mashiinka Kaarboonka safka hore Waxay qaadataa naqshad toosan si loo yareeyo dhererka mashiinka. Markaa way ku habboon tahay xadka qalabka ceyriinka. Sidoo kale waxaa ku jira nidaamka dib-u-warshadaynta qiiqa. Qiiqa lagu dhaliyo hanaanka kaarboonka wuxuu galayaa nadiifinta ka dibna waxaa loo gubaa kuleylka foornada. Maxaa ka badan, Waxay soo saartaa dhuxul dufcadeed, Waqtiga kaarboonka 8-10 saacadood, Waqtiga qaboojinta biyaha 2-3 saacadood, qaboojinta hawada 6-8 saacadood.

Qalabka kaarbooneynta joogtada ah

Doodhyada kaarboon ee joornaalka ah waxay ku habboon tahay xannibidda alaabada biomass ee qaybo yaryar. Markaad u isticmaasho mashiinkan soo saarista dhuxusha, Waxaan soo jeedineynaa cabirka walxaha aan ka weynayn 50mm. In kasta oo ka hartay kaarboonka Rotary Kilrn ay leedahay howsha qalajinta, Uma jeedinayno kaarboonka si toos ah qalabka qoyan, Waxay saameyn ku yeelan doontaa hubooyinkii hungiyoolka iyo tayada dhuxusha. Marka waxaa fiican in la hubiyo in qoyaanka alaabada ay ka yar tahay 30%.

Testing Report of Sawdust Biochar Briquette Made from Charcoal Molding Machine

Halkan waxaan ka xushanahay dhaddaanka Shiinaha ee maxalliga ah si aan u tijaabino tayada dhuxul dhuxul dhuxul. Warbixintu waxay muujineysaa in qiimaha albaabada ah ee dhuxul dhuxul dhuxul ay soo saartay mashiinka aan dhuxul ka soo baxo sadarka 6000 kcal / kg, Qiyaastii waxay labanlaabmaysaa taas oo ah dhadday cayriin (Caadi ahaan 3000-4500 kcal / kg). Waxqabadkaani aad u fiicantahay wuxuu ka dhigayaa dhaarta dhuxul dhuxul oo ilo tamar ah oo hufan oo leh faa'iidooyin dhaqaale oo wanaagsan. Sidaas darteed, Waxaan si daacad ah ugula talineynaa in macmiilku tixgeliyo mashruucan.

|

Nooc |

Dhalay |

|---|---|

| Wadarta qoyaanka MT% |

6.84 |

| Biyaha falanqaynta waalan% |

4.51 |

| Aasaaska ash qalalan |

5.871 |

| Arrinta kacsan oo ku saabsan saldhigga qallalan ee VD% |

20.8 |

| Karbon FCAD% |

68.91 |

| Sulfur waxa ku jira salka qalalan ee st.d% |

0.08 |

| Calororitititititititititir cusub oo heer qaran ah oo ku saleysan qiimaheedka sare ee kcal / kg |

6454 |

| Habka qaranka cusub ee qaran ee qaranku wuxuu helaa qiimaha saldhigga hoose ee saldhiga ah ee kcal / kg |

6088 |

Qorid: Noocyo kala duwan, qoyaan, Cabbirrada alaabta ceeriin, iyo cabirrada farsamada waxay saameyn ku yeelan doonaan natiijooyinka kaarbooneynta biloboon ee billadaha.

Feasibility and ROI of Investment in Sawdust Charcoal Briquette Project

Dhowr arrimood oo muhiim ah ayaa gacan ka geysta rajada faa'iidada ee mustaqbalka ee maalgashiga mashruuca soosaarka dhuxusha ee dhacay. Hadda, Aynu ku galno maalgashigan macaamiisha Kenya.

Waxyaabaha kor ku xusan waa faahfaahin ku saabsan sida loo sameeyo dhuxul dhuxul laga sameeyo dhadday ee Kenya. Sidoo kale, Waxaan sidoo kale ku siin karnaa wax kale Khadadka Waxsoosaarka Dhulka. Sida 3 T / H SHUDUST MUSTERTETE DUMARKA, BBQ BIOChar Friquette iyo badhanka bambaananka ee bambaananka, itc.