Na ho na le moralo oa khoebo bakeng sa sehlahisoa se seholo sa biochar sa biochar ". Ehlile. Re ka u fa 300,000 T / y y colcaling ea ho theha morero. Le ka lebaka la tlhahiso ea hora, e ka fihla 10 T / h. Kahoo e ka fihlela tlhoko ea hau ka botlalo ea Ho etsa lipatlisiso tsa makoloi tsa thuto ea makoloi Ka bongata bo boholo. Holim'a moo, Ho latela litlhoko tsa bahlahisi ba li-striquette tsa mashala, Re hlophisa ka ho khetheha tse fapaneng 300,000 Litsamaiso tsa Tlhahiso ea Tholo ea T / Y y. Joalo ka 300,000 T / y y colcoal tsamaiso ea tlhahiso ea lihlahisoa, 300,000 T / y yo briquette Line, 300,000 T / y y cosqoette square sistimi ea pakete, etc. Haeba u na le litlhoko tse ling, O ka ikopanya le rona hang-hang, Re tla u fa lilakane tsa Bighar tsa Biochar tsa Biochar.

Mokhoa oa ho qala 10 T / h briquete ho etsa projeke ea projeke?

Haeba u batla ho fetoha Biomass Lisebelisoa (raese husk, Bamboo, sawdust, etc) ho li-striquette tsa mashala ka bongata, O ka khetha rona 10 T / h Product Production Production. Ts'ebetsong ena, o hloka mehato e meraro:

Lisebelisoa tsa li-biomass tse bohloko ho phofo e ntle

Mona, Litsela tsa Biomass tsa Bymass ho phofo e ntle ke khetho e loketseng ho nolofatsa ho omella. Hobane boholo ba karohano, sebaka se seholo sa ho ikopanya le ho omella. Ebe ka lebaka la bokhoni bo boholo ba 10 T / h, Re khothaletsa hore u khethe YS-800 Hammer Milla. E se na lebaka le leholo feela empa hape e ka baka lisebelisoa tse ngata tse lekanang le phofo e ntle ntle le.

Litaba tsa ho fetola mongobo

Ka kakaretso, Mofuthu oa lintho tse tala o bapala karolo ea bohlokoa ho ho etsa mashala a khase. Hobane mongobo o ka ama ho tlama pakeng tsa lisebelisoa tse tala. Mongobo o mongata o ka etsa hore thepa e tala e be metsi haholo, Ho fokotsa bokhoni ba bona ba ho boloka le ho etsa hore ho be le mashala tsa mashala ho se matla ka ho lekana. Ka hona, Ho bohlokoa ho fetola mongobo ho 5%-15% Pele ho bichagtte tlhahiso ea biocharte. 'Me u sebelise YS Mochine oa Dister Storyer Storyer e le mokhoa o sebetsang haholoanyane. Empa haeba boitsebiso ba hau e le sawdust, Re ka u fa Moea oa sefofane oa sefofane e loketseng ho omisa likotoana tse nyane.

Ho Sebelisa Bohloeli bo Tsoelang Pele

Ho feta moo, U hloka ho reka mochini o loketseng oa carbonization. Bakeng sa ho etsa Bigchar e kholo, Seballo se tsoelang pele sa khano ke khetho e ntle ka ho fetisisa. Bakeng sa ntho e le 'ngoe, Bokaholimo ba eona ke 1000 kg / h e nang le tlhahiso e tsoelang pele, e nang le mechini e meng e fetang e 'ngoe ea ho ts'oaroa. Kahoo e ka u thusa ho qeta 300,000 T / y y yo biochar progtion production projeke kapele. Bakeng sa e mong, Sesebelisoa sena se amohela tsamaiso ea motlakase ea motlakase ka botlalo. Nakong ea ts'ebetso ea ho sebetsa, Leha e se e le ts'ebetso efe kapa efe, e ka fetola thepa ea biomass ho biochar.

Malebela: Ha u sebelisa mochini ona bakeng sa ho hlahisa mashala, Re khothaletsa boholo ba thepa eseng e kholo ho feta 50mm. Leha carbonozation, rotary ea carbonization kiln e na le ts'ebetso ea ho omella, Ha re fane ka tlhahiso ea ho ts'oasa thepa e nang le metsi ka kotloloho, E tla ama mokhoa oa ho kuta o tšoanang le boleng ba mashala. Kahoo ho molemo ho etsa bonnete ba hore mongobo oa thepa o ka tlase ho 30%. Kahoo o hloka ho sebetsana le lisebelisoa tsa Biomass pele.

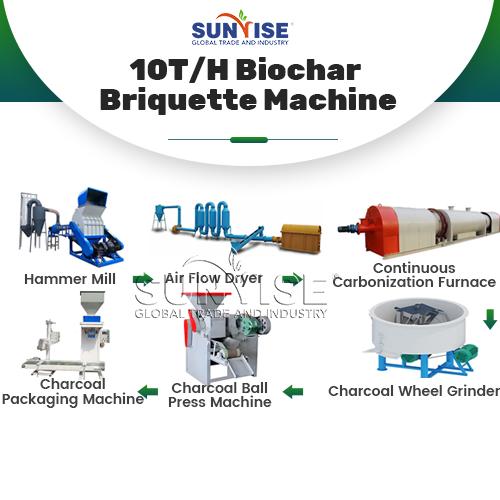

Ke lisebelisoa life tse sebelisoang ho tšobotsi e kholo ea lirique?

Na ho na le moralo oa maphele oa marenene oa mapolanka bakeng sa ts'ebetso e 'ngoe ea biochar? Karabo ke e. Haeba u qetile biochar, O ka reka 300,000 T / y y coscoalte Line ka kotloloho. Nakong ea 300,000 T / y y cosqotte e etsa, U ka hloka lisebelisoa: Mochini oa mashala oa mashala, grinder ea mashala ea mashala.

10T / h package "ea li-briquette tsa li-briquete tse phethiloeng

Ha u qetile mofuta oa brique "e biochar le o batla ho rekisa bareki ba hau, Ho bohlokoa ho sebelisa rona sistimi ea ho paka Bakeng sa mofuta o moholo oa mashala oa mashala oa mashala oa mashala. Hobane tsamaisong ena,

Lisebelisoa tsa li-corcoal tsa boiphetetso li ka u thusa ho paka li-striquette tse felileng 10 KG / Bag, 15 KG / Bag, 30 KG / Bag, 50 kg / mokotla le 65 KG / Bag, etc. Kahoo o ka rekisa li-triquette tsa mashala tsa mashala ho bareki ba hau ka tsela e lebisitsoeng. Bakeng sa bokhoni ba 300,000 Lithane ka selemo, YS STAY Design Round Hookah Charcoal Packing, Cube Shisha Bhachar Mochini oa Pakic, Lihlahisoa tsa BBQ tsa pokello ea masela le lijo tsa mahe a linotsi tsa li-bbOquette tsa lijo tsa hau tsa khetho ea hau.

'Me ho na le metjho e meng e nang le metjha e meng e nang le mochini o potolohileng hookah charcoal packing. Ho na le bothata ba ho lahla thepa le mocheso oa mocheso. Lipina tsa depenser tsa Hookah tsa khaforele li lumella lihlahisoa tsa motho ka mong hore li aroloe. Mochine oa mocheso oa mocheso o ka eketsa lifilimi tsa polasetiki ho ea kantle ho sehlahisoa se ka thibelang lebokose le tsoang ho honotha le ho thibela mongobo. Ka hona ka bobeli ba u thusa ka bobeli ba li-striquette tsa mashala. O ka ba khetha ho latela moralo oa hau oa lichelete.

Mochini o moholo oa Biochar oa Biochar "o etsa bokae?