Due to the fast growth rate of bamboo, cutting down bamboo will not damage the environment. Especially in today’s increasingly important environmental protection, bamboo charcoal briquette is becoming more and more popular in the international market, and the development of mechanism bamboo biochar briquette is very promising. So how to make bamboo charcoal briquette continuously? Ys, as a professional char-molder manufacturer, can provide you with a bamboo charcoal briquette plant. And you can also customize it according to your requirements.

Why do you choose bamboo as material to make biochar briquette?

Choosing bamboo as material to make biochar briquette has three benefits:

The ash produced during the burning of bamboo briquette charcoal can fall off naturally. Because bad charcoal needs to be peeled off manually after producing the ash. Otherwise the burning part will be wrapped in the ash and the exothermic situation is not good. Then good high-temperature bamboo charcoal will fall off layer by layer by itself when burning. Kwa hivyo, the charcoal briquette can always be kept in a high-temperature state.

The appearance of bamboo briquette charcoal is generally better than that of wood briquette charcoal made from Sawdust. They have a neat appearance, no cracks, and a crisp sound can be heard when struck. Kwa kuongeza, bamboo charcoal briquette has high hardness. When bamboo charcoal is naturally thrown down from a height of two meters, the briquette breaks into two pieces with a flat section and no crushed charcoal chips.

Through the test, the burning time of 1 kg of medium temperature mechanism bamboo charcoal briquette was three and a half hours. While the same weight of high temperature bamboo charcoal burned for more than five hours. So the burning time meets the standard.

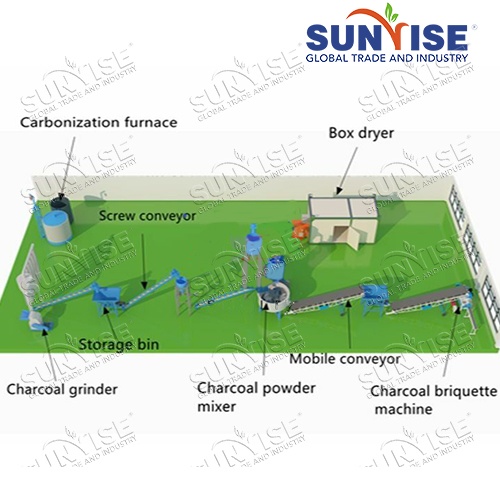

What is the design of automatic bamboo charcoal briquette making system?

For finish bamboo charcoal briquettes manufacturing, we need to buy equipment with a high efficacy. It not only has a suitable capacity but also special designs which are beneficial for faster production. Kwa hivyo, in automatic bamboo charcoal briquette making system, you will choose the machines as follows:

Samani inayoendelea ya kaboni

If you want to purchase an automatic bamboo biochar briquette making line, hii carbonization machine is the best choice. And it can also meet your large scale and continuous production requirement. But you need process the size of feeding bamboo less than 5cm. Kwa hii, you can use a crusher. Then when you prepare to make small scale bamboo charcoal briquette, you can choose hoisting and horizontal carbonization furnace. And you just need to make the bamboo shorter.

Mill ya nyundo

Then for producing bamboo biochar briquette, you also need to crush carbonized bamboo. Kwa hii, we recommend you to choose Mill ya nyundo. It can grind 1000-1500 kg of carbonized bamboo into fine powder per hour. And this crusher has 50 hammers to shredding materials. So it is beneficial for subsequent bamboo biochar briquette production.

Double shaft horizontal mixer

Kwa kuongeza, in bamboo charcoal briquette plant, mixer is also indispensable. It can blend materials with binders evenly, which is beneficial for ensuring the quality of final product. In this bamboo biochar briquette business plan, double shafts horizontal mixer is your best option.

Mashine ya mkaa ya extruder

If you want a commercial charcoal briquette making machine, hii Mashine ya mkaa ya extruder is the best choice. It not only has a cheap price, but also produces large scale briquettes with 1-10 t/h, which can meet your production needs. And we can also provide you with other char-molders.

Mesh belt dryer

Because when you burn bamboo charcoal briquette with high water content, part of the heat will be used to evaporate the water. Thereby reducing its combustion calorific value. And in order to make briquette easy to transport and store, you’d better reduce it to below 5%. In this respect, mesh belt dryer with 100℃-150℃ greatly helpful for you.

What bamboo grinder machine is suitable for you to dispose of bamboo?

In order to make bamboo biochar briquette, crushing is a necessary step in bamboo charcoal briquette plant. So there are two bamboo grinder machines for your choice.

Which charcoal briquette machine can make high quality bamboo biochar briquette?

For better bamboo disposal, many bamboo owners prefer to process it to charcoal briquette. Kwanini? Because preparing bamboo into biochar briquette can get more profits than itself. Nini zaidi, compared to bamboo charcoal, briquettes have higher quality to meet customer’s requirements . For char-molder purchasing, there are some tips for you.

Rod making machine for small scale bamboo charcoal briquette making

If you want to set up a small scale bamboo charcoal briquette plant, we recommend you choose charcoal extruder machine. Generally speaking, inaweza kutoa 1-10 tons of bamboo biochar briquette per hour. Kwa kuongeza, it has characteristics of low investment, over 99% briquette rate, less space occupation. Which helps you start small scale bamboo charcoal briquette making more smoothly.

Charcoal ball press equipment for large scale bamboo biochar briquetting

Provided you need a machine for large scale bamboo biochar briquetting, Mashine ya waandishi wa mpira wa mkaa ni chaguo lako bora. YS-1000, the largest ball press equipment, has a capacity of 40-45 t/h. Kwa kuongeza, in order to prolong its service life, we especially adopt 65 manganese steel casting to make this machine. Kwa ujumla, this machine achieve bamboo charcoal ball production though mechanical force or hydraulic system.

Rotary charcoal tablet press for tablet shape of bamboo charcoal briquette production

But when you want to process cow litter with tablet shape, it is advisable to buy Vyombo vya habari vya mkaa wa Rotary. Because it mainly makes use of the extrusion force from adjustable pressure control system between molds and holes to prepare bamboo charcoal powder into briquettes. And this machine uses stainless steel as material to improve the quality of machine. Kwa ujumla, it can produce 21420pcs/h bamboo charcoal tablets.

Can bamboo charcoal briquette plant withstand the erosion of chemical materials?

Carbonizing bamboo process will cause serious corrosion to equipment. Because the carbonization process is actually the dry distillation process of materials under high temperature conditions. Wakati wa mchakato huu, the organic matter in the bamboo breaks down, producing charcoal, flammable gases (such as carbon monoxide, hydrogen, and methane), acids, and other chemicals.

Can bamboo charcoal briquette plant withstand the erosion of chemical materials? Kwa kweli. The machine material is Q245 R steel and 310S stainless steel, which has high strength and corrosion-resistance. Kwa kuongeza, we can equip equipment with stainless steel lining on your request to insulate erosion. And all easy wear out parts of all bamboo char-molders use Mn steel as manufacturing material. So this bamboo biochar briquette production line can work to produce briquettes for a long time.

Besides this bamboo charcoal briquette plant, YS can also offer you suitable biochar briquette production line with other materials. Such as bbq charcoal briquette plant, biomass charcoal briquette machine and wood biochar briquette making machine, nk. Welcome to contact us immediately for your own charcoal briquette making project.