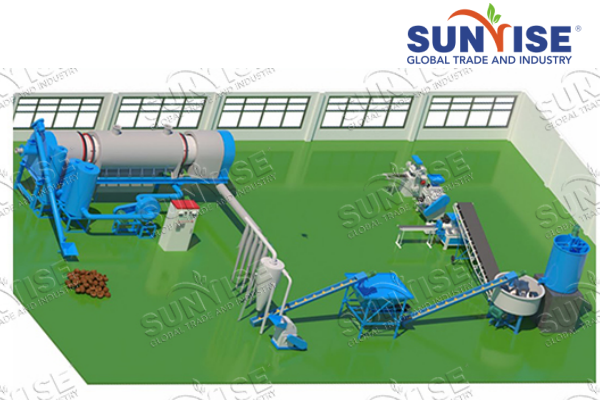

When you want to buy a high quality and suitable charcoal briquette making machine, you need to know the detailed information about machines. Such as raw materials selection, feeding requirements and binder usage. So we especially summarize the 3 things commonly inquired about biochar briquette machine from our customer feedback as follows:

What materials are suitable for using in charcoal briquette machine?

Various materials

Nigbagbogbo, biochar briquette machine can be used to press various powders such as coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, charcoal powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder, …patako ati bẹbẹ. Its purpose is to reduce dust, control bulk density, recycle and improve transportation characteristics, patako ati bẹbẹ. And in 4 types of charcoal briquette machine, these materials are more suitable for Ẹrọ atẹjade Curcoal Board. Then it can also make various fertilizers.

Materials disposal

When you prepare to use these materials to make charcoal briquette, you need to process them. Fun eyi, grinder machine is necessary. There are some shredders for your choice. Such as hammer mill, Raymond mill, patako ati bẹbẹ.

What are the feeding requirements of the char-molder?

There are some requirements for feeding materials to make high quality charcoal briquettes. The following are the detailed information:

What are the precautions for using the charcoal briquette press machine?

If you want to buy a high quality charcoal briquette making machine, you must pay attention to these precautions,which can use for a long time.