Ṣaaju ṣiṣe kan carcoal biquati, Iye idiyele gbọdọ jẹ ibakcdun akọkọ rẹ. Awọn ifosiwewe nọmba wa ti yoo pinnu awọn idiyele owo-inọnwo ti Biour-ruquequettette Ṣiṣe laini pẹlu ipo ti ọgbin ati ohun elo aise. Awọn idiyele le jẹ tito lẹtọ sinu awọn ẹgbẹ meji: Awọn idiyele olu ati awọn idiyele iṣẹ. Iṣeeṣe ọrọ-aje ti curcoquetting ni ipo kan jẹ igbẹkẹle lori bi awọn idiyele wọnyi ṣe ibatan si awọn epo aropo’ owo. Eyi jẹ ọrọ kukuru ti awọn okunfa ti o le ni agba awọn idiyele inawo ti Biochatting.

Capital costs for charcoal briquette plant

Establishing the capital costs of a charcoal briquetting plant is not always a straightforward process. In some cases, there is a lack of general consensus on what exactly should be included as part of capital costs. For instance, spare parts can be classified as both an operational cost and capital cost depending on the circumstances.

Raw materials for biochar briquette making line

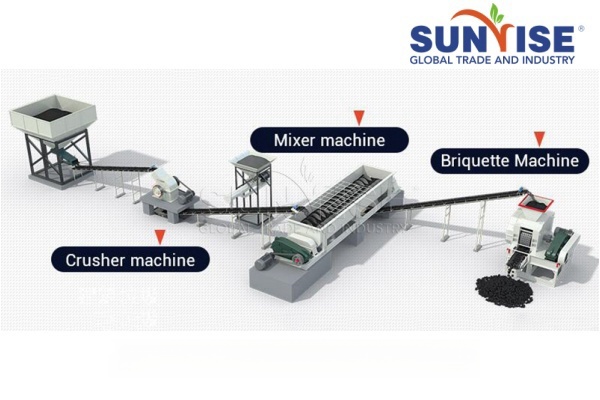

The capital cost of the plant will depend on whether it’s a stand-alone plant or a section of an existing agro plant with available facilities. One major factor that determines the capital costs is the raw material and its form upon collection. The output rate of biochar briquetting machines will vary considerably depending on characteristics of the raw materials such as density.

For instance, wood residues result in higher output than most agro-residues thus incurring lower costs. In other cases, the raw materials may need to undergo pretreatment or other processes such as drying, chipping or shredding before being fed to the briquetter. This will increase the capital cost significantly. One also has to factor in the cost of equipment necessary for the collection of raw materials.

Charcoal briquette plant design

The engineering and design of the charcoal briquetting plant will also affect the capital costs. Spacious buildings are necessary in plants where mechanical handling is minimal or non-existent in order to avoid overcrowding or dustiness. Idle factory where biochar briquetting machines are housed in existing buildings will have lower capital costs.