Med udvikling af miljøvenlig kul, Bortskaffelse af kokosnødder bliver mere og mere vigtig for kulstyring. Men det traditionelle kulfremstillingssystem kan ikke fuldt ud møde kunderne’ Behov. Så vi er nødt til at opgradere det, Og det er et ideelt valg at lave kokosnød til biocharbrikette. Til dette, Ys Kan give dig kokosnødskulbrikette, der planlægger at planlægge dit valg. Hvis du har andre krav. Du kan også kontakte os for tilpasning.

Hvorfor så mange producenter vælger behandling af kokosnød til kulbrikette?

I dag, Mere annonce Flere kulbriketter Producenter vælger at omdanne kokosnøddeskal til Biochar Briquette. Hvorfor? Der er tre grunde:

Sammenlignet med traditionelle kulfremstillingsmetoder, At omdanne kokosnød til biocharbrikette kan reducere forureningen i din fabrik i høj grad. I denne proces, Der er professionelle støvopsamlere til fremstilling af biomassen i biomasse.. Og på grund af høj kvalitet kokosnødbiochar brikette, Det har ingen lugt og røg i brændende processen, som kan beskytte omkring miljøet. Så du kan næsten bortskaffe kokosnød til biocharbrikette uden forurening.

Fordi kokosnødskulbrikette er 100% Ren naturlig kokosnød Biomasse Trækulbrikette uden kemikalier tilføjet, det kan i det mindste brænde 3 timer, hvilket er 6 gange højere end traditionel kulbrikette. Og det endelige produkt har et meget lavere askeindhold (2-10%) end kul (20-40%), som kan garantere kvaliteten af biocharbrikette.

Udover at kokosnødskul brikette selv er god, Coconut Biochar Briquette Making Line er også fordelagtigt for at øge din indkomst. Efter at have drejet kokosnødskal i Biochar Briquette, Du kan sælge det til lokale leverandører. På denne måde, Du kan tjene flere overskud end at sælge kokosnødmateriale direkte.

Hvordan man bortskaffer kokosnødskal til kulbrikette?

Fra ovenstående introduktion, Vi kan vide, at kulbriketteproduktion er et fremragende valg til bortskaffelse af kokosnøddeskal. Men hvordan man laver kokosnødskulbrikette? Her, YS vil designe en kokosnøddelseskort i henhold til dine faktiske forhold.

Carbonize Coconut Shell til trækul

Du kan bruge carboniseringsmaskine til at kulstofisere kokosnøddeskaller direkte i trækul. Så vi har forskellige typer carboniseringsovne, Næsten alle af dem kan bruges til fremstilling af kokosnødskalkul. Til den lille skala kulproduktion, Du kan vælge hejsning og Horisontal karboniseringsovn. Til den store kulfabrik, Du kan vælge Kontinuerlig carboniseringsmaskine.

Kokosnødskalkulsknusning

Kokosnødskalkul holder skallen form eller bryde i stykker efter kulsstoffer. Til dette, Før du laver briketter, du skal Slib dem til pulver. Og trækulpulver er meget lettere for at forme og kan reducere maskinens slid. Hammer Mill og Raymond Mill er de bedste valg for dig.

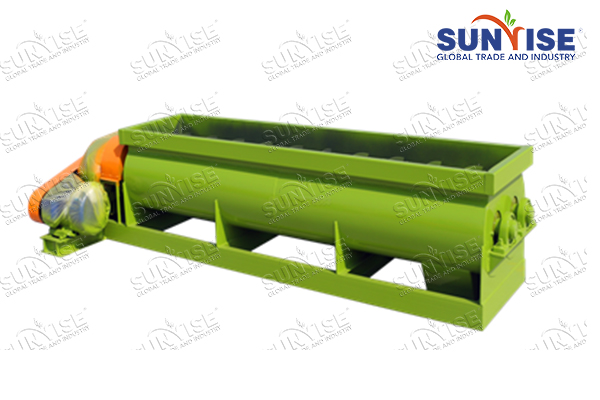

Blanding af kokosnødskulpulver med vand og bindemiddel

Da kokosnødskulpulver ikke har nogen viskositet, Vi er nødt til at tilføje et bindemiddel for at hjælpe det med at danne sig til briketter. Med et bindemiddel, Trækulbriketterne er mere solide, og overfladen er mere glat. Og det mest almindelige bindemiddel er majsstivelse og cassava -stivelse. Fordi de er fødevareklasse og har ingen skadelig gas efter forbrænding. Som regel, Binderforholdet er 3-5%.

Coconut Shell Charcoal Briquetting

Dette trin er det vigtigste i Coconut Shell Biochar Briquette Making. Under høj temperatur og højt tryk, Trækulpulveret briquetting i maskiner. Og der er typer maskine til dit valg. Såsom cHarcoal Rotary Tablet Press, Trækulekstrudermaskine, Trækulboldpressemaskine og Hookah Press Machine. Du kan vælge dem efter dine behov.

Biochar brikette tørring

Alle kulbriketter er våde efter at. Så tørring er nødvendig, før du bruger dem som brændstof eller solgt på markedet. Der er uden tvivl to måder at tørre kokosnødskulbriketterne på. Den ene er naturlig tørring i solen, den anden tørrer af maskinen.

Trækulstørrer

Der er to typer tørretumblere til tørring af kulbriketter: Mesh bæltørrer og tørringsrum.

Hvorfor så mange kokosnøddirektør vælger at købe kulbrikette maskine fra YS?