Anns an àm a dh 'fhalbh o chionn ghoirid, Tha làthaireachd gual-fiodha nàdurrach a 'lùghdachadh. Ach tha an t-iarrtas aige air a bhith àrd fhad 's a tha an solar cuibhrichte. Ann am pàirt air sgàth coilltean lùghdaichte agus a 'mhiann nan craobhan a ghleidheadh. Mar thoradh, Inneal a 'dèanamh inneal-diùid barcoal a 'fàs mòr-chòrdte an-diugh. Agus a 'tòiseachadh air gnìomhachas brùidhteach gual-fiodha a bhith air a bhith na phròiseact prothaideach ann an iomadh dùthaich, Coltach ri Afraga a Deas, Uganda, Kenya, msaa.. Airson seo, Air 19 Giblean 2024, Fhuair sinn brixquette barcoal a 'dèanamh teachdaire à Ceinia. Bha an neach-dèiligidh seo airson breugaire gual-fiodha a dhèanamh bho heathadst. Ach cha robh fios aige dè a tha am pròiseas riochdachaidh. Is e na leanas am fiosrachadh mionaideach sa chùis seo:

Why Is Sawdust Charcoal Briquette Making Popular in Kenya?

Kenya has long relied on traditional wood charcoal for cooking and heating, but with increasing deforestation and the rising cost of fuel, the search for alternative energy sources has become urgent. Anns na beagan bhliadhnaichean a dh 'fhalbh, producing charcoal briquettes from sawdust has gained popularity across the country. This eco-friendly solution not only reduces waste but also provides a sustainable source of income and energy for local communities.

Kenya’s furniture and timber industries generate large amounts of sawdust every day, most of which used to be burned or dumped. By converting this waste into charcoal briquettes, manufacturers can turn low-value residues into high-value fuel. This process helps reduce environmental pollution and promotes circular economy practices.

The Kenyan government encourages renewable energy initiatives and sustainable waste management. Projects that convert agricultural and wood waste into briquettes align with national clean energy goals and often receive support from NGOs and local authorities. This favorable policy environment makes sawdust charcoal production even more attractive to entrepreneurs.

With urban populations expanding and traditional charcoal prices increasing, demand for cheaper and cleaner fuel is growing rapidly. Sawdust charcoal briquettes burn longer, produce less smoke, and are more affordable for households, restaurants, and small industries-making them an ideal alternative in both rural and urban markets.

What Kind of Sawdust Is Used for Making Briquettes in Kenya?

Quality Requirements for Sawdust

The quality of sawdust has a direct impact on the strength, burning efficiency, and appearance of briquettes. Clean and uniform sawdust leads to higher carbonization efficiency and better compression during molding. The raw material should be free from paint, varnish, or chemical residues, as these can produce toxic gases during combustion. Finer particles are preferred because they fill molds evenly and bind more tightly under pressure. Choosing pure, uncontaminated sawdust ensures that the final briquettes are safe, odorless, and environmentally friendly.

How to Control the Moisture Content of Sawdust

Moisture control is one of the most critical factors in briquette production. The ideal moisture content of sawdust is between 8% agus 12%. If the material is too wet, the briquettes will not hold their shape and will take longer to dry after pressing. Air an làimh eile, overly dry sawdust lacks flexibility and reduces the bonding strength between particles.

To achieve the right balance, producers often dry sawdust under the sun or use a rotary drum dryer for faster and more consistent results. During rainy seasons, storing sawdust under a covered shed and using airflow dryers helps prevent moisture absorption. Regularly checking the material’s moisture level before carbonization or briquetting ensures stable production and high-quality briquettes.

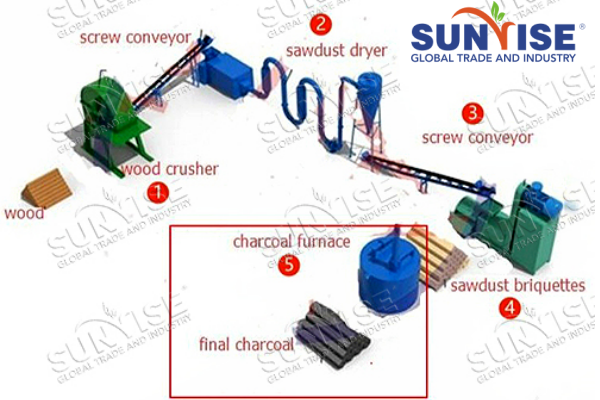

What is the Process of Making Biochar Briquette from Sawdust?

Bha an neach-ceannach Kenyans seo ag iarraidh faighinn a-mach air an Pròiseas airson a bhith a 'dèanamh buriquette BiChare bior. Gu coitcheann, tha 4 ceumannan ann a bhith a 'dèanamh breugain bracoal.

What is the Advantage of Making Sawdust Charcoal Briquette?

Mu dheireadh, Neach-ceannach bho Kenya deiseil airson a dhèanamh min-sàibh breuga na gual-fiodha airson ùine aonaranach. Ach bha dragh aige nach biodh an prothaid cho math ri bhith a 'reic gu robh sàilean sàmhach nàdarra. Mhìnich sinn dha na buannachdan bho bhith a 'giullachd breugain shaorach.

How Much Does a Small&Large Scale Sawdust Charcoal Briquette Plant Cost?

Tha pàirt cudromach aig an comas ann an sàbhaladh plannt plannt boriqual. Meudaich prìs himiquet Biquet Biquette Biquette le comas. Bha an neach-ceannach Kenya seo ag iarraidh oirnn plana prìs a thoirt dha.

How Much Does It Cost to Start a Sawdust Charcoal Briquette Business in Kenya?

Starting a charcoal briquette business in Kenya is one of the most promising clean energy investments today. With abundant sawdust from furniture and wood industries, and growing demand for eco-friendly fuels, our customer is turning this waste into profit. Ach, before launching your briquette project, it’s crucial to understand the initial investment, machine cost, and expected returns.

What Are the Main Costs of Setting Up a Sawdust Charcoal Briquette Factory?

Establishing a sawdust charcoal briquette production line involves expenses for equipment, Stàladh, site preparation, Làbarach, and electricity. The cost largely depends on your desired production capacity and automation level.

| Cost Category | Description | Estimated Cost Range |

| Installation & Commissioning | Machinery setup, test running and technician guidance | $2,000-$10,000 |

| Site Preparation | Factory building, foundation work, ventilation and layout design | $5,000-$30,000 |

| Labor Cost | Operators, technicians and management staff salaries | $2,000-$10,000/month |

| Electricity & Fuel | Power consumption for machines and heat source for drying and carbonization | $1,000-$5,000/month |

| Stuthan amh | Min-sàibh, wood shavings, rice husk or other biomass feedstock | $500-$3,000/month |

| Transportation | Shipping of equipment and raw materials | $1,000-$8,000 |

| Maintenance & Spare Parts | Replacement parts, regular machine maintenance and lubricant | $1,000-$3,000/year |

| Miscellaneous | Licenses, taxes, safety equipment, office supplies, msaa | $1,000-$5,000 |

What Factors Influence the Total Investment of Sawdust Charcoal Briquette Production?

Several factors affect your total startup cost beyond the machines themselves.

Mullach 3 Carbonization Machines for Sawdust Charcoal Briquettes Making

An dèidh beachdachadh air a 'phròiseas, Bha Neach-ceannach Kenyan ag iarraidh a bhith eòlach air nach eil an fhùirneis chaorain as freagarraiche airson a bhith a 'dèanamh weathad meamal.

A 'togail inneal carronization

An A 'togail fùirneis carrain a 'toirt a-steach inneal-togail dealain. Leis an inneal-togail dealain, faodaidh e an tanca a-staigh a thogail gu furasta, a shàbhail cosgais susbaint. Agus tha gach fùirneis uidheamaichte 3 tancaichean a-staigh. Tha an ùine sin aige 8-12 uairean gus dèanamh cinnteach à deagh chàileachd gual-fiodha. Às deidh aon tanca de stuthan a 'crìochnachadh cannon, Faodaidh tu a thogail a-mach leis an inneal-togail agus an uairsin cuir tanca eile de stuthan airson carbad.

Fùirneis gualain còmhnard

Inneal calachalachd còmhnard a 'gabhail ri dealbhadh còmhnard gus àirde innealan a lughdachadh. Mar sin tha e nas goireasaiche airson stuthan amh a luchdachadh. Agus tha e cuideachd a 'toirt a-steach siostam ath-chuairteachadh ceò. Bidh smoc a chaidh a chruthachadh anns a 'phròiseas chataibh a' tighinn a-steach don ghlanadh agus an uairsin a 'lasadh airson a bhith a' teasachadh an fhùirneis. Dè a bharrachd, Bidh e a 'dèanamh gual-fiodha le baidse, Ùine Carbony 8-10 uairean, Ùine fuarachadh uisge 2-3 uairean, fuarachadh adhair 6-8 uairean.

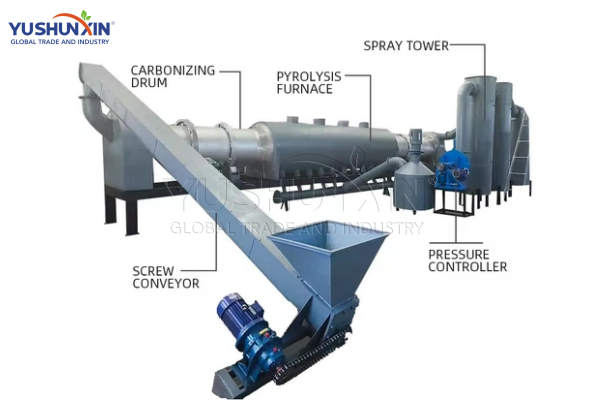

Uidheamachd carrain leantainneach

Fùirneis gualain leantainneach freagarrach airson na stuthan bith-chonnadh a tha ann am pìosan beaga. Nuair a chleachdas tu an inneal seo airson gual-fiodha a dhèanamh, Tha sinn a 'moladh meud stuthan nach eil nas motha na 50mm. Ged a tha aig Kingn Rotary Red Knen a 'tiormachadh, Chan eil sinn a 'moladh gual Lochlannach, Bheir e buaidh air a 'chàileachd gualain a' charbonying agus càileachd gual-fiodha. Mar sin tha e nas fheàrr gu bheil an taiseachd stuthan nas lugha na 30%.

Testing Report of Sawdust Biochar Briquette Made from Charcoal Molding Machine

An seo tha sinn a 'taghadh sàim-sàbhalaidh ionadail ionadail gus deuchainn a dhèanamh air càileachd bior-chùalaich. Tha an aithisg a 'nochdadh gu bheil luach càirdeil an t-sàim-sàbhalaiche-fiodha a tha air a thoirt a-mach leis an inneal seo a tha air a thoirt a-mach le ar n-inneal-sàbhalaidh boriqual boriqual air a dhol thairis air 6000 Kcal / kg, Bidh timcheall air a bhith a 'dùblachadh an t-seam nightust (mar as trice 3000-4500 Kcal / kg). Bidh an coileanadh sònraichte seo a 'dèanamh heathad mightust biorcolte stòr lùth earbsach agus èifeachdach le deagh bhuannachdan eaconamach. Mar sin, Tha sinn a 'moladh gu dùrachdach gu bheil neach-ceannach a' beachdachadh air a 'phròiseact seo.

|

Seòrsa |

Min-sàibh |

|---|---|

| Mt% taiseachd iomlan |

6.84 |

| Uisge anailis a 'faicinn% |

4.51 |

| Tow Sture Ash ad% |

5.871 |

| Cruan luain air VD% |

20.8 |

| FCad carbon stèidhichte |

68.91 |

| SULLUUR CLÀRADH AIR A DHÈANAMH GU FHIOSRACHADH THRED STE. |

0.08 |

| Stèidheachd ùr Stor Cortory àbhaisteach CalORemy Cortory Cruinneachadh KCAL / KG |

6454 |

| Bidh an dòigh aig Calorimeter Coitcheann Ùr a 'faighinn a' bhunait Còraichean Coillbheit ìosal KCALT / KG |

6088 |

Nota: Diofar sheòrsan, taiseachd, meudan stuthan amh, agus Paramadairean teignigeach a 'toirt buaidh air na toraidhean carronan biomage.

Feasibility and ROI of Investment in Sawdust Charcoal Briquette Project

Bidh grunn phrìomh nithean a 'cur ri na dùilean prothaid gealltanach a bhith a' tasgadh ann am pròiseact riochdachaidh carcoal. A-nis, Bheir sinn a-steach don t-thasgadh seo airson neach-ceannach Kenya.

Tha na h-àrd gu h-àrd mion-fhiosrachadh mu mar a nì thu brivequette gualcoal bho hipder ann an Ceinia. A bharrachd air, Faodaidh sinn cuideachd fear eile a thabhann dhut cuideachd Lainns riochdachaidh Brivequal Brixquette. Leithid 3 Inneal biorcoal connach, Plannt a 'dèanamh bbq bycharte agus Lusan brùideil bambù, msaa.