With the development of environmental friendly charcoal, coconut shell disposal becomes more and more important for charcoal management. But the traditional charcoal making system cannot fully meet customers’ needs. So we need to upgrade it, and making coconut into biochar briquette is an ideal choice. Don wannan, Ys can provide you with coconut charcoal briquette making plans for your choice. If you have any other requirements. you can also contact us for customization.

Why so many manufacturers choose processing coconut into charcoal briquette?

Nowadays, more ad more charcoal briquettes manufacturers choose to turn coconut shell into biochar briquette. Why? There are three reasons:

Compared with traditional charcoal making methods, turning coconut into biochar briquette can greatly reduce the pollution in your factory. In this process, there are professional dust collectors for biomass charcoal briquette manufacturing. And because of high quality coconut biochar briquette, it has no odor and smoke in the burning process, which can protect around environment. So you can nearly dispose of coconut into biochar briquette without pollution.

Because coconut charcoal briquette is 100% pure natural coconut biomass charcoal briquette with no chemicals added, it can burn for at least 3 sa'ad da, which is 6 times higher than traditional charcoal briquette. And the final product has a much lower ash content (2-10%) than coal (20-40%), which can guarantee the quality of biochar briquette.

Besides coconut charcoal briquette itself being good, coconut biochar briquette making line is also beneficial for increasing your income. After turning coconut shell in biochar briquette, you can sell it to local suppliers. Ta wannan hanyar, you can make more profits than sell coconut material directly.

How to dispose of coconut shell into charcoal briquette?

From the above introduction, we can know that charcoal briquette production is an excellent choice for coconut shell disposal. But how to make coconut charcoal briquette? nan, YS will design a coconut disposal plan according to your actual conditions.

Carbonize coconut shell to charcoal

You can use carbonizing machine to carbonize coconut shells into charcoal directly. So we have different types of carbonization furnaces, almost all of them can be used for making coconut shell charcoal. For the small scale charcoal production, you can choose the hoisting and horizontal carbonization furnace. For the big charcoal factory, you can choose the continuous carbonizing machine.

Coconut shell charcoal crushing

Coconut shell charcoal keeps the shell shape or break into pieces after carbonizing. Don wannan, before making briquettes, you need to grind them into powder. And charcoal powder is much easier for shaping and can reduce the wearing of the machine. Hammer mill and Raymond mill are the best choices for you.

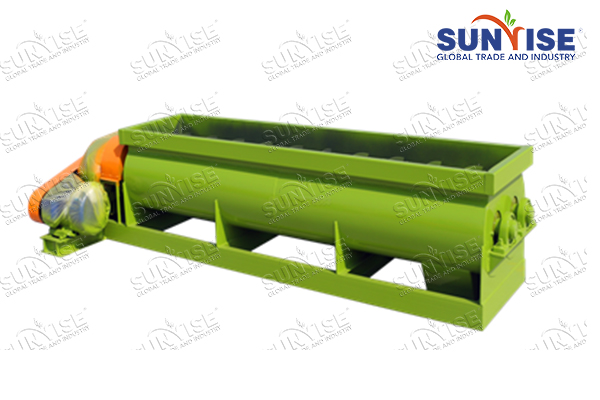

Mixing coconut charcoal powder with water and binder

As coconut charcoal powder has no viscosity, we need to add a binder to help it form into briquettes. With a binder, the charcoal briquettes are more solid and the surface is more smooth. And the most common binder is corn starch and cassava starch. Because they are food grade and have no noxious gas after burning. Kullum, the binder ratio is 3-5%.

Coconut shell charcoal briquetting

This step is the most important in coconut shell biochar briquette making. Under high temperature and high pressure, the charcoal powder is briquetting into machines. And there are types of machine for your choice. Such as charcoal rotary tablet press, injin gawayi, carcoal ball Latsa inji da hookah press machine. You can choose them according to your needs.

Biochar briquette drying

All of the charcoal briquettes are wet after being produced by the charcoal briquette machine. So drying is necessary before using them as fuel or sold on the market. No doubt there are two ways to dry the coconut charcoal briquettes. One is natural drying in the sun, the other is drying by machine.

Charcoal dryer

There are two types of dryers for drying charcoal briquettes: mesh belt dryer and drying room.

Why so many coconut manager choose to buy charcoal briquette machine from YS?