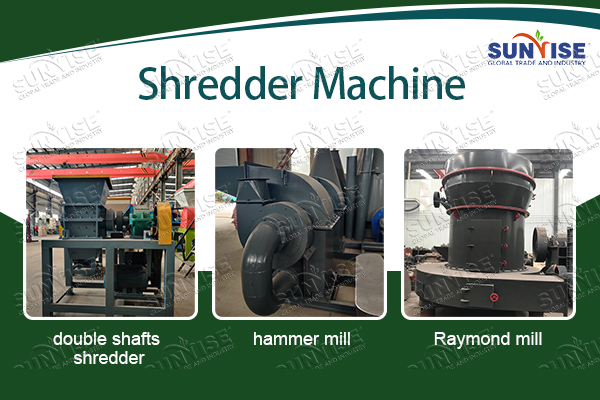

Charcoal grinder machine is an important equipment in charcoal briquette production line. And YS can provide you with six crushers for your choice. Such as hammer mill, mobile wood crusher, mobile disc type tree stump shredder, double shafts shredder, charcoal wheel grinder and Raymond mill. You can choose them according to your needs. And we can also customize crushers according to your actual production condition. If you are interested in it, please contact us immediately.

What can charcoal grinder machine do for quality biochar briquette making?

Whether you want to make shisha charcoal briquette or start a wood biochar briquette production project, charcoal grinder machine is necessary. Why? Because it can crush your materials into fine powder quickly and easily. This is greatly beneficial for your charcoal briquette manufacturing in the following three aspects:

How to choose a commercial wood crusher for your charcoal briquette making?

As mentioned above, both before briquetting and carbonization, it is advisable to use charcoal grinder machines. しかし, how to purchase suitable biochar crusher for your commercial charcoal briquette manufacturing? 一般的に, you need to pay attention to material capacity and types. According to this, we design commercial charcoal grinders as follows:

High efficiency wood hammer mill

When your materials are branches, wood shavings, sawdust, ストロー, cotton and corn stalks, 等, you can use this machine to process materials. And there are two types of hammer mills for your choice. Small capacity hammer mill (small hammer mill) and large capacity hammer mill (large hammer mill). Each hammer mill has its own special features and advantages.

Small hammer mill

It has two different driving forces: electric motor and diesel engine. And this kind of hammer mill cuts large pieces of materials with the diameter around 30mm into smaller pieces with the diameter from 2mm to 5mm. So you can grind materials with a high effect. 加えて, it adopts high-speed strong wind suction grinding system and dust suction device. このために, you don’t worry about the problem of production environment. Its capacity can get 100-2100 kg/h.

Large hammer mill

This wood hammer mill adopts welded-steel plate construction, which can increase pulverizing efficiency by 15%. And it reduces a broad variety of friable and fibrous materials into very fine products in uniform size ranges from 20 to 300 mesh. What’s more, this series of wood hammer mill have an extra quarter screen located in the hinged section of the top case, increasing screen area by approximately 50% over that of conventional designs, for a total of 270°. And it can grind 1-4 t/h materials.

Mobile wood crusher for sale

Mobile wood crusher is not restricted by region and energy. So two types of mobile wood shredder are the best choices for you. Industrial wood chipper and mobile disc type tree stump shredder. You can choose them according to your needs.

What equipment can be used for crushing charcoal?

Besides crushing different types of raw materials, charcoal grinding is also important. In YS, you can purchase the following charcoal grinder machines:

It can not only grind charcoal but also mix with water and binders. And it usually consists of two or more rotating grinding wheels with a certain gap between them. Through the action of rotation and extrusion, the material is ground into the required particle size or shape. したがって, this machine is an ideal equipment for producing charcoal briquettes.

Raymond mill

This machine can also grind charcoal into fine powder. During work, Raymond mill mainly relies on internal grinding rollers and grinding rings to crush materials. After feeding charcoal pieces into the pulverizer, the material dipper will send the material between the grinding roller and the grinding ring. 同時に, due to the centrifugal force from rotation, the grinding roller swings outward and presses against the grinding ring. So the charcoal between them will be crushed into biochar powder quickly.