The Philippines has a tropical maritime climate with lush vegetation, which has been the main output area of wood. Nanging ana kondomot sing kudu fokus. How to dispose of wood waste? Converting it into charcoal briquette is an excellent choice. Ing proses iki, briquetting is necessary. Kanggo iki, you need to know what char-molder is suitable for you. So on 25th February 2022, a customer from Philippines inquired about small scale charcoal briquette making. The following are the specific information in this case:

The requirement of the Filipino client for small scale biochar making

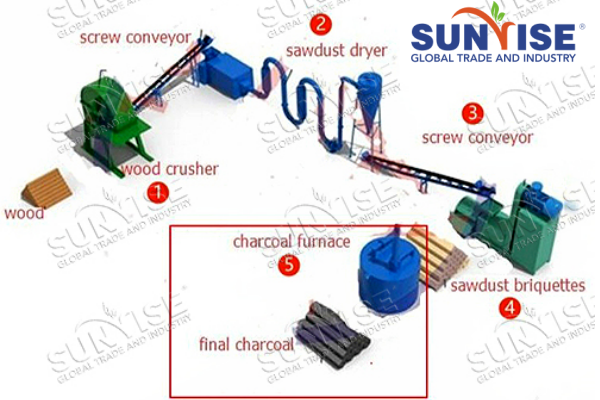

The customer from Philippines planned to make sawdust, Kripik kayu, coconut shells and rice straws, lsp kanggo nggawe Briquette Biochar. And the capacity is 500 kg / h. Kajaba iku, he told us “ …What I want is a recommendation from you of the components of the process required from crushing to drying to briquetting and carbonation and packaging. And I need a quote for the complete set up. Then I will then need help with your team coming to set it and get it running and then hand over the process …”

What is the component of small scale biochar briquette system?

This Filipino client wanted us to give him an advice about the component of small scale charcoal molding system from crushing to drying to briquetting and carbonation and packaging. Kanggo iki, we discuss this situation according to customer’s actual condition:

Why so many customer choose YS small scale charcoal briquette making system?

Rega Pabrik Sumber

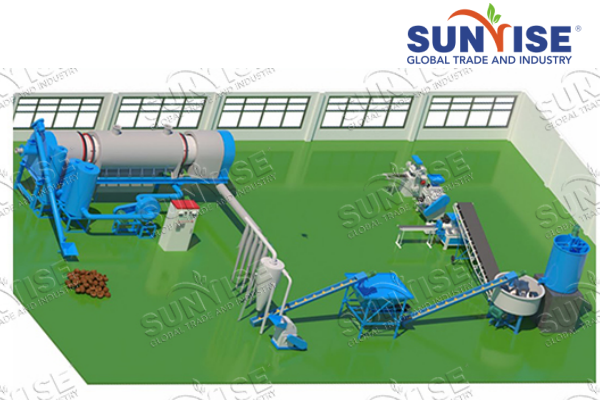

As a leading char-molder manufacturer in China, Ys has its own charcoal briquette machine manufacturing factory, kang udakara 40.000º. So you can buy charcoal molding equipment at a source factory price. Ora ana biaya tambahan, Dadi kudu dadi rega sing paling disenengi. And if you want to setup a complete small scale biochar briquette system, you need about $80,000-$150,000 with the 500-1000 ㎡area. This price is only a reference cost, if you want to know the detailed price, please contact us.

Complete after-sale service

After buying our small scale biochar briquette plant, you don’t worry installation and equipment running. Our team will hand over the whole process from buying to installation to running. And we also provide proof of free warranty within one year. If you choose us, you will never regret.