The Philippines has a tropical maritime climate with lush vegetation, which has been the main output area of wood. But there is a concomitant that needs to focus on. How to dispose of wood waste? Converting it into charcoal briquette is an excellent choice. In hoc processu, briquetting is necessary. Hoc, you need to know what CHAR-MOLOREN is suitable for you. So on 25th February 2022, a customer from Philippines inquired about small scale charcoal briquette making. Et haec sunt specifica notitia in hoc casu:

The requirement of the Filipino client for small scale biochar making

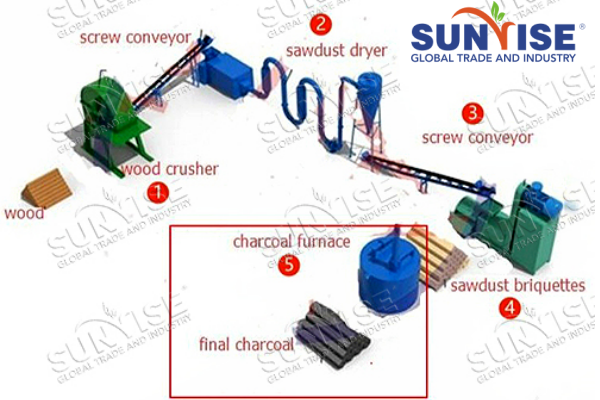

The customer from Philippines planned to make sawdust, lignum eu, coconut shells and rice straws, etc to make biochar briquettes. And the capacity is 500 kg / h. Praeter, he told us “ …What I want is a recommendation from you of the components of the process required from crushing to drying to briquetting and carbonation and packaging. Et opus est pro rata completa. Tunc opus erit auxilio tuo venienti turmae ad eam pone et adipiscendi currendo et processum trade …"

Quod est elementum parvae systematis briquette biochar?

Hic Cliens Filipino nos consilium dare voluit de componentibus minoris pretii carbonis fingens ratio a terendo ad siccando ad briquetting et carbonationem et packaging. Hoc, de hac condicione secundum condicionem emptoris disputamus:

Why so many customer choose YS small scale charcoal briquette making system?

Source factory price

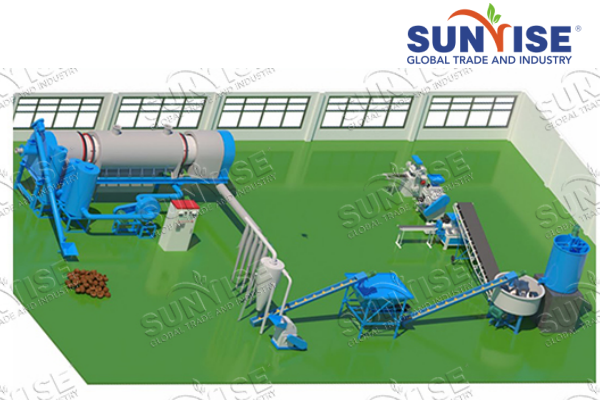

As a leading char-molder manufacturer in China, Ys has its own charcoal briquette machine manufacturing factory, which is about 40,000㎡. So you can buy charcoal molding equipment at a source factory price. There is no extra charge, so it must be the most favorable price. And if you want to setup a complete small scale biochar briquette system, you need about $80,000-$150,000 with the 500-1000 ㎡area. This price is only a reference cost, if you want to know the detailed price, please contact us.

Complete after-sale service

After buying our small scale biochar briquette plant, you don’t worry installation and equipment running. Our team will hand over the whole process from buying to installation to running. And we also provide proof of free warranty within one year. If you choose us, you will never regret.