Charcoal extruder machine is a kind of briquette machine through using the screw structure to make rod shape briquette. And the most common use of this machine is for charcoal briquetting. So there are two methods. The one is molding first and then carbonization. The other one is that directly get rod shape briquettes (charcoal as materials). Hei taapiri, if you want to start continuous charcoal briquettes production, Ka taea hoki e tatou te whakatutuki i o hiahia.

What materials are suitable for charcoal extruder processing?

Ka hiahia koe ki te mahi i nga Briffettes mai i te miihini hira o te biochar, Me awangawanga koe mo te whiriwhiri i nga taonga. Pēnei i te momo, Te rahi me te makuku, take. Ko nga korero e whai ake nei ko nga korero:

Nga momo rauemi

Haunga te karawaka, Ka taea hoki e tenei miihini taapiri te whakaputa i nga briffettes mai i te koke, poka, Olive Pomacy, mātaiwa me te ngahere ngahere, take. He rereke nga taonga mata e rite ana ki nga momo mahinga o Briquettes rereke. Na he mea nui te kowhiringa o nga rauemi.

Nga whakaritenga o nga taonga

Mena kei te hiahia koe ki te hanga i nga kaihokohoko kounga teitei, Me whiwhi nga rauemi i etahi whakaritenga. Mo tenei, Ko te rahi o nga rauemi he iti ake te nuinga o te waa 3-5 mm. Me 10-14 % He tino makuku mo te mahi a Briquette i runga i te utu o te briquette briquette. Tuhinga o mua, Ka taea e koe te hanga i te briffette me etahi atu makuku, Engari he maha nga ngoikoretanga. Me te makuku iti, Ko te raru ka nui te mea ka puta ake te putanga Briquette. Na, ki te mea ko te briffette me te makuku tiketike, Ka ngawari, ka kaha ake te waa ki te maroke.

He aha etahi atu whakaritenga mo te whangai rauemi i roto i te tangohanga o Charcoal?

Ko nga rauemi kai ki roto i te taapiri whakairo e hiahia ana kia pai te whakarite kia pai ai te whakaputa me te tino-kounga nui. Anei etahi whakaritenga me nga whakaaro nui:

Ma te whakarite kia tutuki enei whakaritenga, Ka taea e te tino huringa te whakahaere, te whakaputa i nga bribeets kounga nui e tika ana mo te whakamahi hei wahie.

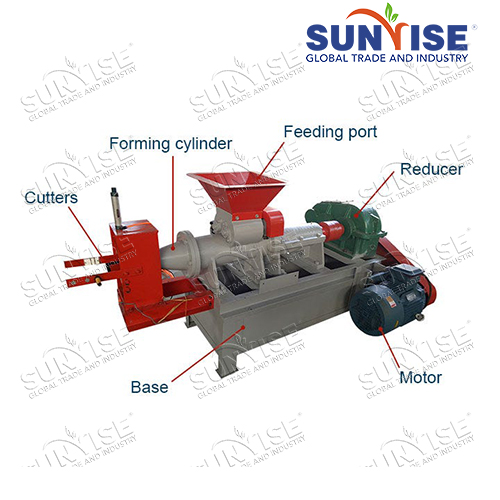

He aha te kaupapa o te miihini e mahi ana i te miihini taapiri?

Haere, Ko te huringa hurihuri e pa ana ki te pehanga, te akiaki i nga taonga ngoikore na roto i te mate me te ahua o te briquette motuhake me te rahi. Ka rite ki nga taonga e haere ana i te mate, ka whakapakaritia e ratou, te hanga i nga briquettes carcoal piri. Rawa, Ko nga Briquid Briquiltes ka tapahia ki te roa e hiahiatia ana ma te whakamahi i te tikanga tapahi. Na kua oti nga hua kua oti mo te kapi, te whakamahi wawe ranei.

Runga 2 Ko nga tikanga whakaputa briffettes i roto i te tangohanga o te Charcoal mo to whiringa

There are two briquettes production methods for your choice. The one is molding first and then carbonization. The other one is that directly get rod shape briquettes, which use charcoal as materials. The detailed information is as follows:

Ko tehea te momo o te miihini hinonga koiora e tika ana mo o mahi briffette?

AhauKei te noa te ahua o nga kaihoko rereke he rereke nga hiahia me nga whakaritenga i roto i te mahinga. Hei kaiwhakarato ngaio me te whakaaro nui, tātou Whakahoahoa nga momo taapiri motika mo koe. Ahakoa he iti koe, Te raina whakatipu nui, te rahi ranei, Ahakoa e hiahia ana koe ki te whakaputa i nga kaihokohoko whakairo, i etahi atu biffette ranei, Ka taea e ratou te whakatutuki i o hiahia. I roto ia ratou, YS-140 ko te mea me te putanga iti, mō 1-2 tara / h. He mea whiriwhiri mo koe, Mena kei te hiahia koe ki te tiimata i tetahi tauine iti i hangaia. Ko te putanga nui rawa atu ko YS-210, mō 3-4 tara / h, He pai mo te raina whakatipuranga Siffettes i te raina.. Mena ka hiahia koe ki te nui o te tauine nui ake, Ka taea e koe te whakamahi i te miihini hiipene YS-400 BioChar hei hanga i nga Briffette. Ka taea e tana kaha te tiki 6-10 t / h.

| Āhua | YS-140 | YS-180 | YS-210 | YS-300 | YS-400 |

|---|---|---|---|---|---|

| Raukaha | 1-2 t / h | 2-3 t / h | 3-4 t / h | 3-5 t / h | 6-10 t / h |

| Te tohu tohu | 20-40 | 20-60 | 20-80 | 20-80 | 20-80 |

| Tuhinga o mua | 46-60 r / min | 39-60 r / min | 35-60 r / min | 35-60 r / min | 35-60 r / min |

| Tuhinga o mua | 4 | 4 | 4 | 4 | 4 |

| Miihini hiko | Y160m-4 11kW

Y160L-4 15KW |

Y180m-4 18.5kW

Y180l-4 22kW |

Y200L-4 30kW

Y225G-4 37KW |

Y225G-4 37KW

Y225m-4 45kW |

Y315M-4 160kW |

| Ruku whakaheke | Zq350 | Zq400 | Zq500 | Zq650-750 | Zq850 |

He aha etahi atu miihini e hiahia ana koe ki te hanga i te kounga nui o te biocherte kounga nui?

Haunga te miihini nui o te miihini, Kei reira etahi atu miihini ka awhina i a koe ki te whakaputa i te rod tino kounga o te rod bioche siffettes. (Ko nga taputapu e whai ake nei ko te whirihora noa i te taha o te hipoki.)

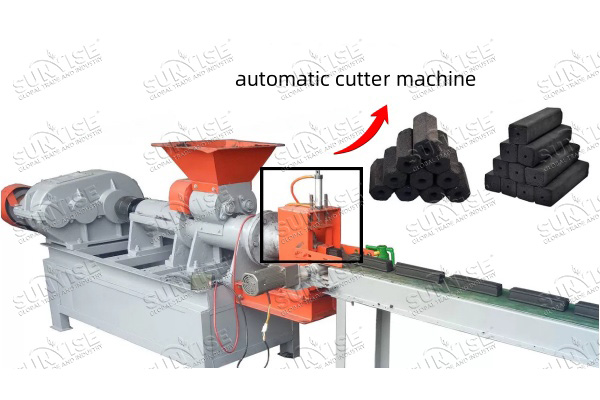

miihini tapahi aunoa me nga taputapu taapiri

In order to meet customer's requirements about the length of charcoal briquettes, we usually equip charcoal extruder with an automatic cutter. It can cut the briquettes automatically to the same length. This small device increases production efficiency a lot and improves the appearance of the biochar briquettes.

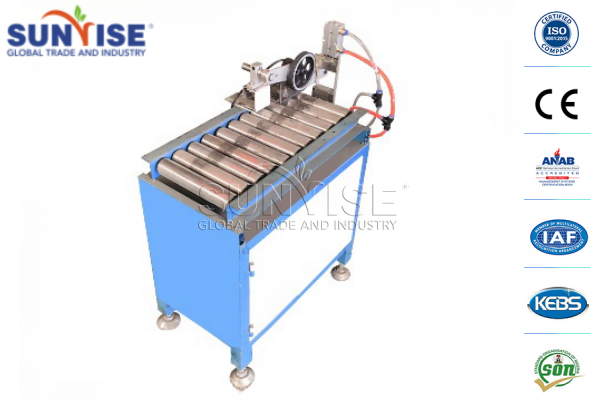

conveyor with rod charcoal briquette making machine

In addition to transporting materials, the conveyor belt also helps shape the charcoal sticks after producing. Because the biochar rods that have just been produced are very hot and soft overall. If you directly connect the packaging bag after making charcoal sticks, it will damage the integrity of the biochar sticks. Mo tenei, Ko te mahi a te Kuwhera a Conveyor ko te tuku i nga rakau biochar hou i hangaia kia whakamatao me te whakakotahi i te hau maori i te wa o te waka. Ko tenei huarahi ka taea e koe te whakapai ake i te kounga o to hua whakamutunga.

Me pehea te mohio ki te whakaputa haere tonu o nga Brifinetes mai i te Biochar Excroder?

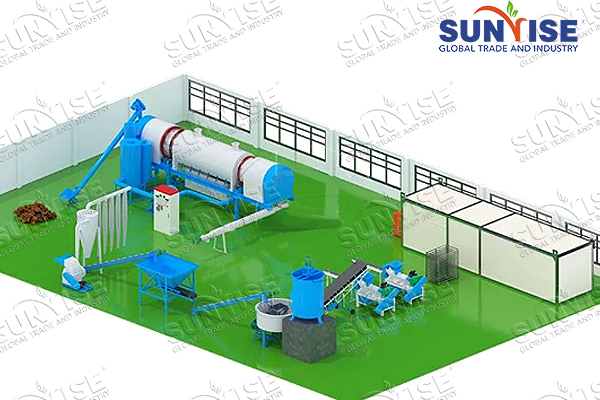

Ka rite ki whakahuahia i runga ake nei, Ka whakaratohia e matou te whakauru whaihua o te Pressrar Sharting Expring hei whakakapi-anake. Katahi ka taea e ia te whakaputa i nga briquilt siffettes tonu? Tuhinga o mua. Ka taea e koe te hoko miihini hipärcoal me te whakakotahi i te miihini hiwi, titi, whakaranu, Te oumu waro me nga taputapu kapi. Ka hangaia e ratou he raina hangai nui i roto i te raina briffette, Nei e whakarite kia taea e koe te kawe i nga kaihokohoko kounga o Biochettes ki o kaihoko tonu.

Me pehea te hua whakamutunga i hangaia e te kaiwhakaputa BioChar?

Na roto i te whakamahi i nga momo hanga ahua rereke, Ka taea e taatau te whakaputa momo momo o Briquettes. Na ko te mea ngawari te whakarereke i te whakarereke me te ora ratonga roa. So you can use just one machine to manufacture different briquette to meet your customers' need.

He aha te utu o te miihini miihini nui o te tipu miihini?

Ko te utu ko te nuinga o te utu hei mahi nui i roto i te miihini whakato miihini nui. Na i runga i nga tikanga o te utu, Ka taea te wehewehe i to maatau BioChar Lize te raina kia toru nga waahanga:

Why do you invest in the charcoal briquettes production business with rod making machine?

He rongonui te mahi a te Briquettes Charcoal na te mea he pai te painga o te umanga. Ko te tikanga whakaputa rongoa tuku iho kua whakakapihia e nga tikanga tukatuka hou o te ao. I muri i te charcoal briquette tangohanga, Ka taea te whakahaere i nga momo ahua me nga whakaritenga, e hangai ana i nga bripetes siffette he ataahua ake i te ahua me te mohio. I roto i te tukanga tukatuka i nga pereti miihini, Ko nga kaiwhakatakoto Bioche Chafineettes hoki te whakanui ake i te uara o a raatau hua, a na reira ka whiwhi moni nui ake.

Me pehea te tiaki i te miihini nui?

What are the different cutting method in charcoal extruder machine?

He aha koe i whiriwhiri ai i te kaihanga briquette briquette, kaua ki te miihini o te miihini pereti briquette briquette?

Ko te tangohanga Briquette Kaihanga me te miihini pereti a Briquette Briquette ko te miihini biquette tino rongonui i roto i te mahi a te umanga umanga. Na, kahea koe e whiriwhiri ai i te tangohanga Briquette ki te hanga i tetahi tipu nui e hanga ana i te Charcoal Briquette? Ko nga painga o te tangohanga briquette e whai ake nei:

Factors affecting the forming of charcoal briquettes

In the production process of charcoal briquettes, there are some factors that will affect the molding effect of briquettes. And customers need to pay attention to them when using them.