The biomass charcoal briquette machine is an environmentally friendly project that processes solid fuel pellets from all kinds of biomass wastes such as straw, takken, and rice husks. So more and more biochar briquette manufacturer prefer to invest in char-molders. But how to make charcoal briquette from biomass? Hiervoor, YS, as a professional charcoal briquette making machine manufacturer, can provide proposals in many aspects. Including material selection, factory location, char-molder choosing, enz.

Why do you start the biomass biochar briquette production business?

What equipment is required for biomass charcoal briquette making?

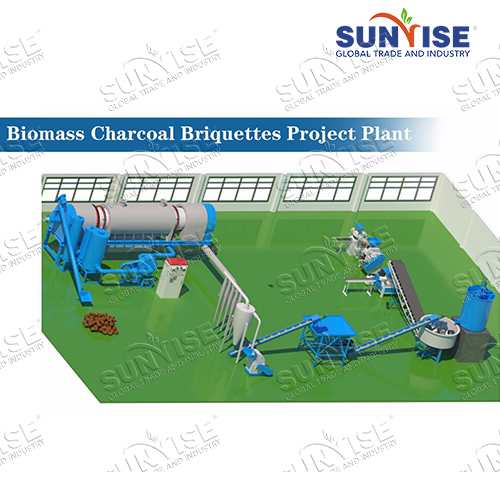

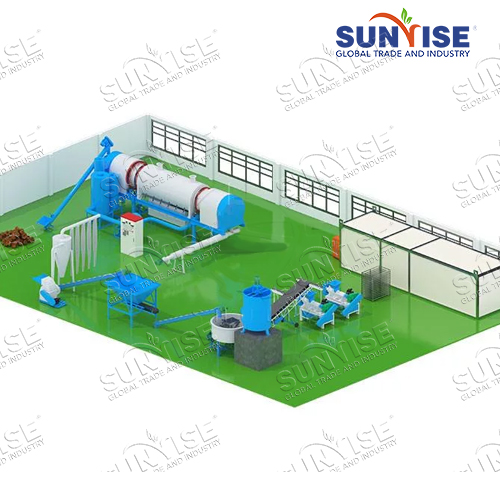

How to prepare biochar briquette from biomassa? What biomass charcoal briquette machines can be used? They are two things you must know when you plan to make biomass material into charcoal briquette. As a professional char-molder manufacturer, YS design various biochar briquette making machines for your choice. And in general, a complete biomass charcoal briquette manufacturing system consists of the following machines:

Carbonisatieoven

If you want to prepare charcoal briquette, carbonization furnace is necessary. Hence, hoisting carbonization machine, horizontal carbonization furnace En continuous carbonization equipment are all excellent choices for carbonizing completely. You can choose them according to your the size of material.

Crushing machine

In the whole sets of biomass charcoal briquette machine, breker is essential. It is used to convert carbonized biomass into fine powder. Then in order to make high quality biochar briquette, we recommend you buy Raymond mill and hammer mill.

Mixing and pressing equipment

At this step, for the final product having a long burning time and molding tightly, you can add some adhesives and accelerants. So wheel mill machine is the best choice for you. It can not only mix materials, but also press them which is the same as grinding.

Biomass charcoal briquette machine

In biomass biochar briquette production, the importance of houtskoolbriketmachine is beyond doubt. Hier, there are various types of char-molders for your choice. Flat die pellet mill, ring die pellet machine, Koolcoal extrudermachine, hookah press machine and biochar ball press equipment. And they can help you produce biomass charcoal briquette according to your needs.

Mesh riemdroger

Freshly produced biomass charcoal briquettes will become very soft and have more moisture, making them easily damaged. For better packaging and storage, drying is essential. We recommend you a mesh belt dryer with a length of 6-40m and an effective width of 0.6-3.0m. Because the hot air flows through the charcoal briquettes, and the water vapor is discharged from the vent, so as to achieve the purpose of drying.

Charcoal packing machine

Packaging is the final step of biomass biochar briquette production. With charcoal packing machine, you can pack your charcoal briquette into bags with different volumes. Op deze manier, you can deliver your briquettes to different customers in a targeted way.

2 Items you need to consider when setup a biomass charcoal briquette making line

In het algemeen, when you plan to establish a biomass biochar briquette manufacturing factory, you must consider the following 2 items:

For commercial biomass biochar briquette making, suitable equipment choosing is important. Op deze manier, you can prepare biomass into the required charcoal briquette effectively and economically. Then what equipment is commonly used in biomass biochar briquette production? The above has the detailed introduction.

Besides machines buying, you also need to choose a suitable place to install them and start your biomass charcoal briquette making. Ten eerste, it should be away from residential areas and easily accessible. Voor een ander, what's more, it must be big enough to accommodate your biomass char-molders. If you have a factory site, we can design a plant layout according to the details you tell us.

What is the price of biomass charcoal briquette machine?

YS biomass charcoal briquette making line is an ideal choice for turning biomass into biochar briquette at a low cost. Then what is the precise quote of biomass charcoal briquette machines? Gebruikelijk, the cost of biomass biochar briquette manufacturing project is not fixed. It is related to many factors including capacity, briquette equipment manufacturer, enz.

Prices of different capacities biomass biochar briquette production systems

Algemeen, the larger the capacity, the higher the cost. So the price of a 500-1000 kg/h biomass charcoal briquette preparation line is $10,000-$50,000. When the output increases to 1000-2000 kg/h, je moet je voorbereiden $50,000-$70,000. How about 2000-3000 kg/h? Its cost is between $70,000-$100,000.

Why YS can provide you with biomass char-molder economically?

Ten eerste, we are the source factory for charcoal briquette equipment manufacturing. There is no extra charge during biomass charcoal briquette making machine buying. Voor een ander, we have been focusing on the production of char-molder equipment for nearly 20 jaar. We adopt advanced technology and equipment. So we have the strength to offer you quality biomass charcoal briquette machine at a favourable price.