Ettersom kundene krever trekull av høyere kvalitet, Flere og flere biokarprodusenter er tilbøyelige til å lage kull. Enten det er hookpyd. For å imøtekomme deres behov, Våre ingeniører designer forskjellige karboniseringsovner for ditt valg. Deretter gjennom analysen av gjeldende data, Vi sommerlige 3 Hot salg av karboniseringsovner, som er populære blant våre kunder. Du kan velge en i henhold til dine behov.

No.1 heise karbonisatormaskin

Denne typen karboniseringsovn er den vanligste karbonisatormaskinen. Og det kan produsere trekull fra sagflisbriketter, tre, bambus, Kokosskall, Risskall, Agro avfall, osv. Så hvorfor trenger du å velge denne maskinen?

Karbonisering av materialer enkelt og raskt

Med den elektriske heisen, den kan løfte den indre tanken enkelt, som sparer arbeidskostnad. Og hver ovn er utstyrt med 3 indre stridsvogner. Da er karboniseringstid 8-12 timer for å sikre god kvalitet på kull. Etter at en tank med materialer er ferdig med karbonisering, Du kan løfte den ut ved heisen og deretter legge en annen tank med materialer for forkulling.

Har forskjellige design

I tillegg, Vertikal karboniseringsmaskin har også mange andre forseggjorte design. De kan tilby deg en bedre karboniseringsopplevelse. Først, Den har to ovner, Intern ovn og ekstern ovn, som har en høyere kullproduksjonshastighet. Og den indre komfyren og ovndekselet er utstyrt med hengende ører som kan hektes. Derfor, Det er praktisk å oppgradere relatert tilbehør under drift.

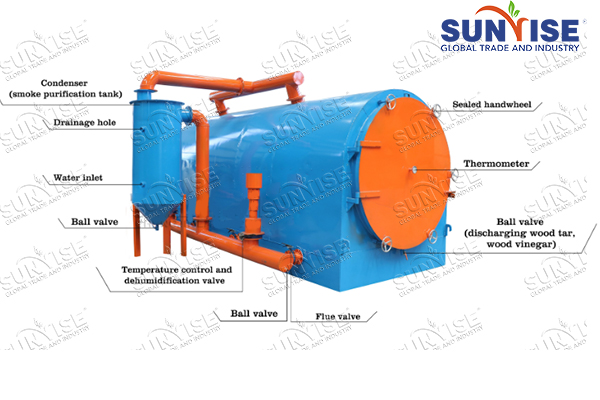

Nr.2 Horisontal karboniseringsovn

Horisontal karboniseringsmaskin er en ny type biochar som lager utstyr. Den vedtar en horisontal design for å redusere maskinhøyden. Så det er mer praktisk å laste inn råvarer. Hva er de andre fordelene med horisontal karbonisatormaskin?

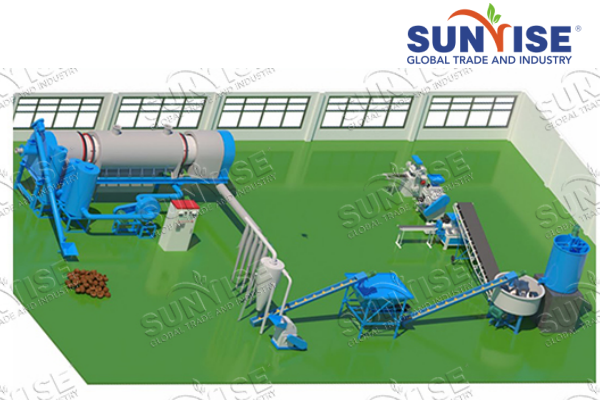

Nr.3 Kontinuerlig karboniseringsmaskin

Sammenligning med ovennevnte karboniseringsovner, Karbonisering RotasjonsovnSin største funksjon er å produsere kull kontinuerlig, ikke batchproduksjon. Og hele kullproduksjonsprosessen er røykfri, og ingen forurensning til miljøet. I tillegg, Den vedtar en dobbeltsylindret struktur. Denne designen gjør at materialet tumler fra den indre ovnen til den ytre ovnen i en sirkel. Det vil si, Innløpet og utløpet av materialene karboniseringsovn er på samme side. Hva er mer, Kapasiteten er den største skalaen i disse maskinene, som kan bli 100-3800 kg/t.