As customers require higher quality charcoals, more and more biochar manufacturers are inclined to make charcoal. Whether it is hookah charcoal or BBQ biochar. In order to meet their needs, our engineers design various carbonization furnaces for your choice. Then through the analysis of current data, we summery the 3 hot selling carbonization furnaces, which are popular among our customers. You can choose one according to your needs.

NO.1 Hoisting carbonizer machine

This type of carbonization furnace is the most common carbonizer machine. And it can produce charcoal from sawdust briquettes, lemn, bambus, coji de nucă de cocos, coajă de orez, agro wastes, etc.. So why do you need to choose this machine?

Carbonizing materials easily and quickly

Cu palanul electric, poate ridica cu ușurință rezervorul interior, care economisesc costul forței de muncă. Și fiecare cuptor este echipat cu 3 rezervoare interioare. Then carbonizing time is 8-12 ore pentru a asigura calitatea bună a cărbunelui. După ce un rezervor de materiale termină carbonizarea, îl poți ridica de palan și apoi pune un alt rezervor de materiale pentru carbonizare.

Having various designs

În plus, vertical carbonization machine also has many other elaborate designs. They can offer you a better carbonization experience. Primul, it has two furnaces, internal furnace and external furnace, which has a higher charcoal production rate. And the inner stove and the furnace cover are equipped with hanging ears that can be hooked. Prin urmare, it is convenient to upgrade related accessories during operation.

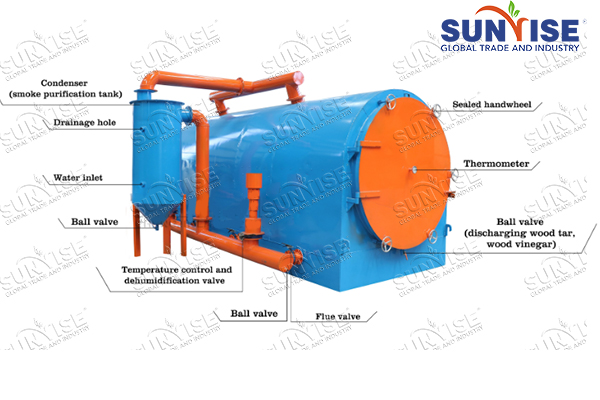

NO.2 Horizontal carbonization furnace

Mașină de carbonizare orizontală is a new type of biochar making equipment. It adopts a horizontal design to reduce machine height. Deci este mai convenabil pentru încărcarea materiilor prime. What are the other advantages of horizontal carbonizer machine?

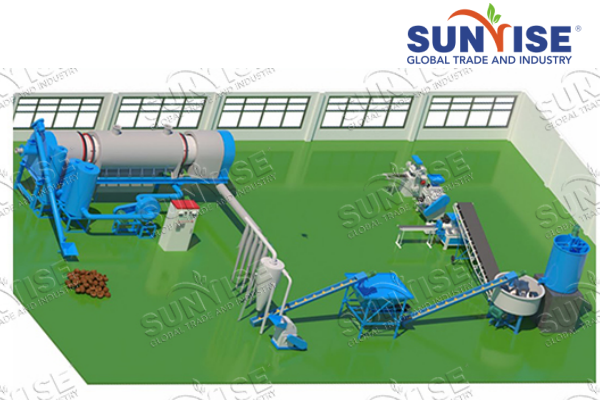

No.3 Continuous carbonization machine

Comparing with the above carbonization furnaces, cuptor rotativ de carbonizare’s greatest feature is to produce charcoal continuously, not batch production. And the entire charcoal production process is smokeless, and no pollution to the environment. În plus, it adopts a double-cylinder structure. This design makes the material tumbling from the inner furnace to the outer furnace in a circle. That is to say, the inlet and outlet of the materials carbonization furnace are on the same side. Ce mai mult, its capacity is the largest scale in these machines, which can get 100-3800 kg/h.