With the development of environmental friendly charcoal, coconut shell disposal becomes more and more important for charcoal management. But the traditional charcoal making system cannot fully meet customers’ needs. So we need to upgrade it, and making coconut into biochar briquette is an ideal choice. Для этого, Да can provide you with coconut charcoal briquette making plans for your choice. If you have any other requirements. you can also contact us for customization.

Why so many manufacturers choose processing coconut into charcoal briquette?

Nowadays, more ad more charcoal briquettes manufacturers choose to turn coconut shell into biochar briquette. Почему? There are three reasons:

Compared with traditional charcoal making methods, turning coconut into biochar briquette can greatly reduce the pollution in your factory. В этом процессе, there are professional dust collectors for biomass charcoal briquette manufacturing. And because of high quality coconut biochar briquette, it has no odor and smoke in the burning process, which can protect around environment. So you can nearly dispose of coconut into biochar briquette without pollution.

Because coconut charcoal briquette is 100% pure natural coconut biomass charcoal briquette with no chemicals added, it can burn for at least 3 часы, which is 6 times higher than traditional charcoal briquette. И конечный продукт имеет гораздо более низкое содержание золы (2-10%) чем уголь (20-40%), который может гарантировать качество брикета биочара.

Помимо самого кокосового древесного угольного брикета, Кокосовая линия изготовления биочарных брекет также полезна для увеличения вашего дохода. После переворачивания кокосовой раковины в брикете биочара, Вы можете продать его местным поставщикам. Таким образом, Вы можете получить больше прибыли, чем продавать кокосовый материал напрямую.

Как утилизировать кокосовую раковину в древесную брикету?

Из приведенного выше введения, Мы можем знать, что производство углевых брикетов является отличным выбором для утилизации кокосовой оболочки. Но как сделать кокосовый угольный брикет? Здесь, YS разработает план утилизации кокоса в соответствии с вашими фактическими условиями.

Карбонизировать кокосовую оболочку до древесного угля

Вы можете использовать карбонизационную машину для напряжения карбонизации кокосовых оболочек в древесный уголь. So we have different types of carbonization furnaces, almost all of them can be used for making coconut shell charcoal. For the small scale charcoal production, you can choose the hoisting and Горизонтальная карбонизация печи. For the big charcoal factory, you can choose the continuous carbonizing machine.

Coconut shell charcoal crushing

Coconut shell charcoal keeps the shell shape or break into pieces after carbonizing. Для этого, before making briquettes, you need to grind them into powder. And charcoal powder is much easier for shaping and can reduce the wearing of the machine. Hammer mill and Raymond mill are the best choices for you.

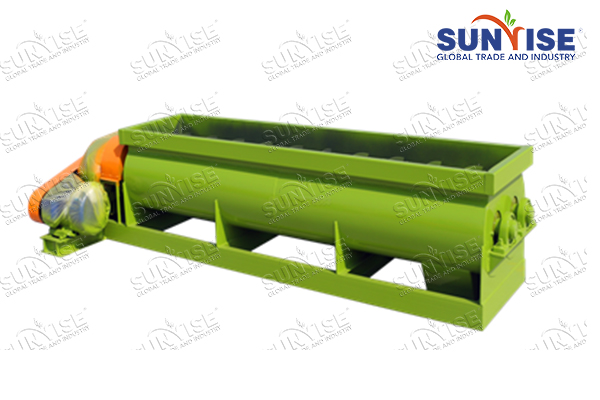

Mixing coconut charcoal powder with water and binder

As coconut charcoal powder has no viscosity, we need to add a binder to help it form into briquettes. With a binder, the charcoal briquettes are more solid and the surface is more smooth. And the most common binder is corn starch and cassava starch. Because they are food grade and have no noxious gas after burning. Обычно, the binder ratio is 3-5%.

Coconut shell charcoal briquetting

This step is the most important in coconut shell biochar briquette making. Under high temperature and high pressure, the charcoal powder is briquetting into machines. And there are types of machine for your choice. Such as charcoal rotary tablet press, Угольный экструдерный аппарат, Угольный шарик для прессы и Машина для прессы кальяна. You can choose them according to your needs.

Biochar briquette drying

All of the charcoal briquettes are wet after being produced by the charcoal briquette machine. So drying is necessary before using them as fuel or sold on the market. No doubt there are two ways to dry the coconut charcoal briquettes. One is natural drying in the sun, the other is drying by machine.

Charcoal dryer

There are two types of dryers for drying charcoal briquettes: mesh belt dryer and drying room.

Why so many coconut manager choose to buy charcoal briquette machine from YS?