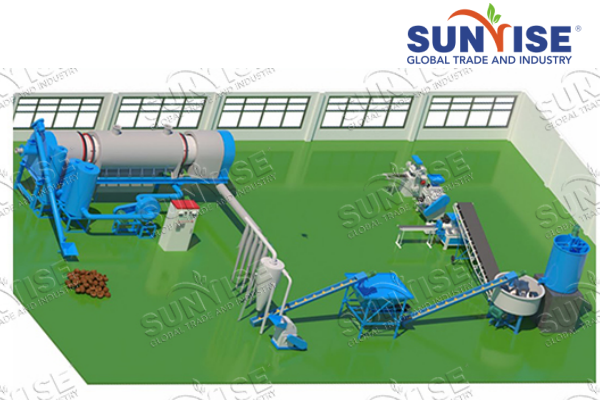

Ni South Africa, awọn ohun elo aise lọpọlọpọ ti o le ṣe ilọsiwaju sinu ọja ti ọrọ-aje. Ṣugbọn bi o ṣe le sọ awọn ohun elo silẹ lati gba awọn ere diẹ sii? Fun eyi, onibara lati South Africa yan lati yi wọn pada si awọn briquettes eedu. Ṣugbọn bi o ṣe le ṣe awọn briquettes eedu? Ni ọjọ 10 Oṣu Kini 2024, onibara South Africa beere nipa iṣẹ akanṣe fun ṣiṣe awọn pellets biochar. Lẹhin ti o ṣe akiyesi awọn ipo gangan ati awọn ibeere lati ọdọ alabara, a ṣe apẹrẹ a 1 t / h Charcoal Ikọ-Kaquequet ni atẹle:

Awọn ohun elo aise wo ni o dara fun iṣelọpọ eedu briquette?

Bii o ṣe le dinku akoonu ọrinrin ti awọn ohun elo lati ṣe briquette eedu didara ga?

What is the application of biochar briquette in South Africa?

This South African customer prepares to use sugar cane, corn stalks, rice husk and wheat straw, etc as biomass materials. These materials are suitable for making biochar briquettes. Why do you choose to turn these materials into biochar briquettes? Ni Gbogbogbo, charcoal briquette has a variety of uses in South Africa, including agriculture, energy, water and livestock.

South Africa has a very small proportion of arable land. Biochar briquette can be used to increase the nutrient and water storage capacity of soil.

Barbeque (Braai) is a traditional food in South Africa. Charcoal pellets are suitable for using as fuel for barbecues. And South Africa relies on coal-fired power generation. So using charcoal as fuel for factories can appropriately alleviate local energy shortages.

The activated carbon is a good material for removing odors and impurities from water.

Ni South Africa, there are a large number of farms. You can add biochar briquettes to feed to improve animal digestibility. And charcoal briquette can be used to absorb gases emitted by animals. This helps reduce greenhouse gas and ammonia emissions. Then adding an appropriate amount of biochar pellets to the animal manure mat will help reduce odor and drain water. Eyi ṣe alabapin si ilera ẹranko.

Bii o ṣe le ṣe eedu lati awọn ohun elo biomass ni South Africa?

Lẹhin ti oye awọn lilo ti eedu briquette, onibara lati South Africa pinnu kedere lati gbe awọn pellets biochar. Ṣaaju ṣiṣe awọn briquettes eedu, o nilo lati carbonize awọn ohun elo ti. Kíláàsì èédú wo ló yẹ fún ọ?

Agbara ti o yẹ

Onibara yii le gba 50 toonu ti awọn ohun elo baomasi fun ṣiṣe biochar. Nitoripe oṣuwọn carbonization gbogbogbo jẹ 30%, o nilo eedu sise ẹrọ pẹlu ohun o wu ti 1 t / h. Nibi,YS-1912 Rotari eedu kiln le ṣe 900-1100 kg ti eedu lati awọn ohun elo biomass fun wakati kan. Ki o le ni kikun pade awọn ti o tobi asekale biochar sise ti 1 t / h.

Carbonizing awọn ohun elo baomasi ni kiakia

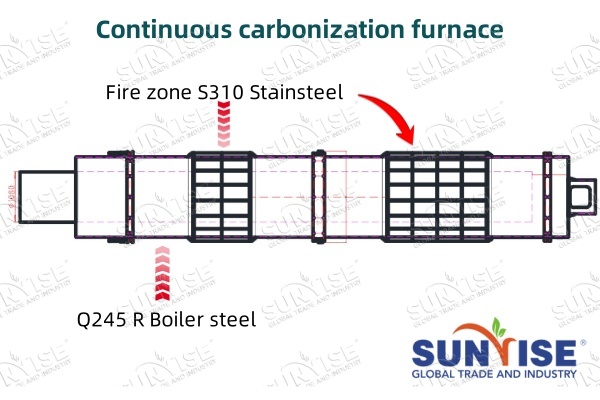

Tiwa Lemọmọmọmọmọniolization carbonace ni awọn abuda kan ti eto iṣakoso PLC, aiṣe-taara ọna, Q245 r, irin + 310S stainless steel materials use, patako ati bẹbẹ. So during the pyrolysis of biomass, the temperature inside the rotary drum can reach 550°C-650°C. Ni ọna yi, you complete the biomass waste within 30 min.

Making biochar environmentally and friendly

Ni afikun, YS-1612 rotary kiln also can help you make charcoal with a low energy consumption and no smoke. There is a gas dust treatment system designed for it. The system can purify combustible gas from carbonization. Then you can use the purified gas as a heat source for subsequent process of tea cuttings to biochar.

What other carbonization machines can make biomass charcoal?

Besides continuous carbonization furnace, ẹrọ carlenetizer ẹrọ ati Tẹ ẹrọ cabenist can also make 1 t/h biomass charcoal. But you need to turn biomass materials into rod shape briquettes firstly. Nitoripe awọn ibeere ifunni wọn jẹ awọn ohun elo ti o ni apẹrẹ. Nitorina eedu extruder ẹrọ jẹ pataki. Fun eyi, bawo ni hoisting carbonization ẹrọ ati ipele iru carbonization ẹrọ ṣe baomasi eedu?

Ẹrọ carlenetizer ẹrọ

Pẹlu ifilọlẹ ina, O le gbe ojò inu ni irọrun, eyiti o fi iye owo laala pamọ. Ati ileru ti ni ipese pẹlu 3 Awọn tanki inu. Lẹhinna akoko carbonizing rẹ jẹ 8-12 Awọn wakati lati rii daju didara ti o dara ti eedu. Lẹhin ojò kan ti awọn ohun elo pari chenelenic, O le gbe jade nipasẹ gbigbemi lẹhinna fi awọn ohun elo miiran ti awọn ohun elo fun gbigbe.

Snace Carbont carbone

O nmu eedu jade nipasẹ ipele. Ati awọn oniwe-carbonizing akoko 8-10 wakati, omi itutu akoko 2-3 wakati ati air itutu 6-8 wakati. Kini diẹ sii, ara ileru rẹ ni awọn ipele mẹta. Ikun inu jẹ gbigbe ooru giga ati irin-inira irin fun jijẹ iwọn otutu carbonetig. Awọn lode Layer ti wa ni ya irin. Layer arin jẹ idabobo okun silicate Aluminiomu. L'akotan, ẹnu-ọna ileru ti wa ni edidi pẹlu iṣakojọpọ seramiki.

Kini ibeere ti eedu fun ṣiṣe awọn briquettes?

Onibara yii lati South Africa fẹ lati mọ ibeere ti eedu. Awọn ibeere mẹta wa ti eedu fun ṣiṣe awọn briquettes ti o ga julọ. Iwọn, ọrinrin ati Asopọmọra. O nilo lati ṣatunṣe eedu gẹgẹbi awọn ibeere wọnyi.

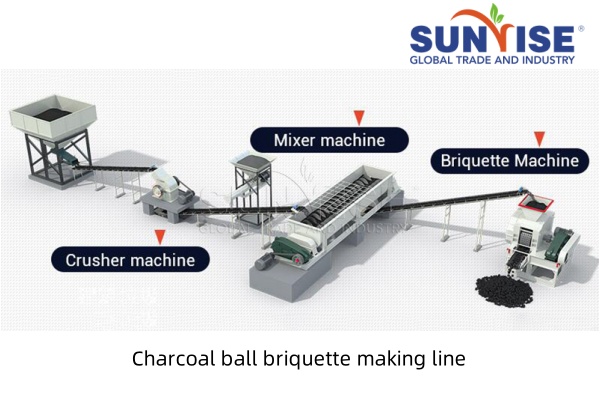

Iwọn eedu yẹ ki o kere ju 5mm ki o le ni rọọrun tẹ wọn sinu awọn briquettes. Fun diẹ ninu awọn eedu ti o tobi bi eedu odidi, eedu ikarahun agbon, patako ati bẹbẹ, o jẹ dandan lati lo eedu crusher lati fọ o sinu lulú ṣaaju ki o to tẹsiwaju si igbesẹ atẹle ti dapọ.

Ọrinrin ti eedu fun ṣiṣe awọn briquettes wa ni ayika 30%. Nitorinaa ọrinrin to dara dara fun awọn briquettes ti o dagba ati jijẹ iwuwo ti awọn briquettes eedu.

Nigbagbogbo, Apapo jẹ pataki fun awọn eedu briquettes processing. Nitori binder le ṣe awọn eedu briquettes diẹ ri to ati ki o dan. Ati ohun elo ti o wọpọ julọ jẹ sitashi agbado tabi sitashi cassava. Ti o dara ju binder fifi oṣuwọn ni 4%-6%. Awọn alabara kan tun wa ti o ṣafikun imudara ijona lati yara iyara ina ti eedu. Ko si binder tabi ignite isare oluranlowo, o le lo aladapọ eedu lati da erupẹ eedu pọ pẹlu omi ati afikun boṣeyẹ.

Oke 3 eedu briquette sise ero fun o fẹ

Onibara South Africa yii murasilẹ lati yan ẹrọ briquette biochar ti o dara. Nitorina a ṣafihan 4 eedu briquette ero fun o fẹ.

Awọn rola briquette ẹrọ titẹ mu ki a lemọlemọfún eedu briquette ilana pẹlu tobi agbara. Pẹlu briquetter kan, agbara le ani lati 35 t / h. Ati pe briquette tun rọrun lati wa ni aba ti pẹlu awọn ẹrọ iṣakojọpọ. Nitorina o jẹ olokiki julọ ni ile-iṣẹ naa.

Extrusion briquette alagidi jẹ ẹrọ briquette ti o dara julọ fun ṣiṣe briquette eedu ni ile-iṣẹ. The shape of the briquette is much different from the roller briquette presses, the briquette is made with low energy cost. And it usually adopts two charcoal briquette making methods.

Shisha charcoal briquette machine adopts a double-pressing design. It consists of a set of molds arranged in a tray. When the machine is working, the mold rotates and compresses the charcoal powder into a tablet or cube shape.

Which one is more profitable between charcoal briquettes and biomass pellets?

L'akotan, Charcoal briquettes and biomass pellets are all biomass fuels that is now very hot business project around the world. Many people who are interested in or want to invest in biomass industry are wondering which one can make much more money? Gaan, the two biofuels have many commons as well as many differences.

They are both made from sawdust wood residue and other agricultural and forestry waste, and they are both used as fuels for civil and industrial industry. Sibẹsibẹ, if you are going to start charcoal briquette manufacturing business or biomass pellet production plant, you should clearly know that biomass pellets and charcoal briquettes are targeted at different customers.

Nitori naa, before starting it, it is very important to find the right customers for your charcoal briquetting factory or pelletizing plant. Because of different demands, the profitability of biomass pellet and charcoal briquettes could not be completely compared. Sibẹsibẹ, as long as adopting scientific management and finding out the accurate customers, you will be successful and gain profits from your own biomass pellets or charcoal briquettes manufacturing business.

Six Recipes for Making Charcoal Briquettes

Kini apẹrẹ ti $100,000-$300,000 cost charcoal briquette plant?

This customer form South Africa prepare to use $100,000-$300,000 to finish charcoal briquette manufacturing. Then for the $100,000-$300,000 aṣaro, we recommend you the following two charcoal briquette manufacturing lines, which are popular with charcoal briquettes suppliers.

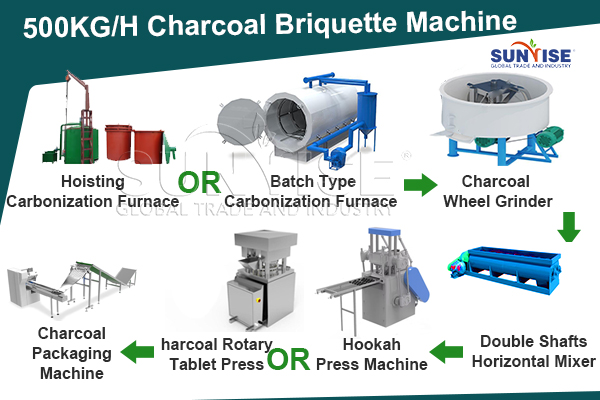

500 kg/h charcoal briquette manufacturing investment

As for charcoal briquette making with $100,000-$300,000, o le ra wa 500 kg/h hookah press line. It includes hydraulic and mechanical method. So its briquetting rate can reach over 95%. After carbonization, parin, mixing and charcoal briquette making, you also need to use dryer to remove excessive moisture from produced charcoal briquettes. L'akotan, packaging biochar briquettes into bags.

1000 kg/h biochar briquette making budget

Pẹlu $150,000-$300,000 aṣaro, you can enlarge the biochar briquette production line scale to 1000 kg / h. Correspondingly, the charcoal forming equipment in this production line will be upgraded. It employs batch type carbonization machine, Curcolil keke grainder, ilọpo meji sluft, ede curcoal, mesh belt dryer and automatic packaging scale. They have a large capacity and can help you produce charcoal briquettes more quickly.

4 Main factors affect the cost of charcoal briquette plant

L'akotan, according to the above budget, this South African customer wanted to know where else to spend money besides buying equipment. Ni Gbogbogbo, for charcoal briquette plant cost, we mainly consider it from 4 aspects. Including material, equipment, running and area.

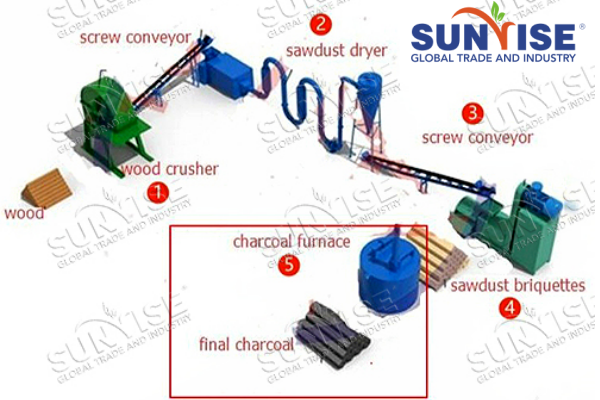

Eyi ti o wa loke jẹ awọn alaye nipa ibaraẹnisọrọ wa pẹlu alabara nipa bi o ṣe le ṣe awọn briquettes eedu ni South Africa. Ni afikun, a tun le fun ọ ni ọpọlọpọ awọn iṣẹ akanṣe eedu miiran. Bi eleyi sawdust biochar briquette sise tabi wood to charcoal, coconut shell to shisha charcoal, patako ati bẹbẹ.