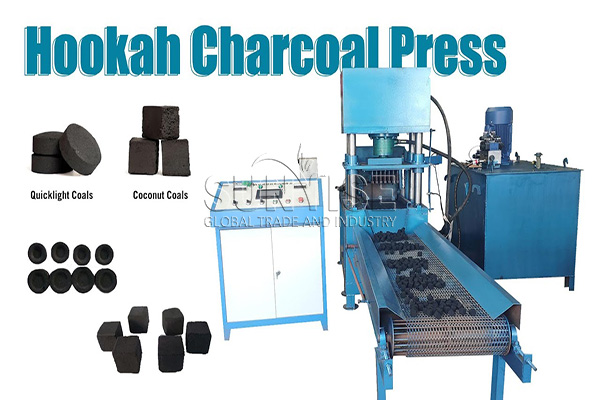

Hookah press machine is a type of machine for making shisha charcoal. When you use this machine to make hookah biochar, the final product is easy to burn for a long time and don’t have odor. Ni afikun, this equipment can replace various molds according to your requirements. Such as producing cube, round, square and rectangular shape, patako ati bẹbẹ. Shisha hookah press machine is suitable for producing large scale charcoal briquettes. So it is an ideal machine for continuous hookah charcoal briquettes production.

What material is suitable for hookah press machine?

As we all know, there are many materials that are very suitable to make charcoal, such as husk, waste wood leftovers, ẹka, awọn igi pẹlẹbẹ, nutshells and so on. Sibẹsibẹ, the material to make hookah is much stricter, because of the high-quality requirement. Nitori naa, coconut, ọparun, orangewood, lemonwood, and other fruitwood are the best raw materials for charcoal.

Oke 2 shisha hookah pressing machine for your choice

Ninu ys, we provide various kinds of hookah charcoal briquette machines, including mechanical shisha biochar maker and hydraulic shisha charcoal machine. The following are the detailed information:

Mechanical shisha biochar maker

This charcoal machine uses the pressure generated by mechanical power to squeeze the biochar block into a specific shape. The operation of the hookah charcoal press is very simple. So you can replace the extrusion die of the hookah charcoal press and process various shapes of hookah charcoal blocks. The shape of hookah briquettes can be a cube, diamond, ring, triangle and disc, patako ati bẹbẹ. And you can also engrave the user’s company name, brand name and logo, patako ati bẹbẹ. on the charcoal.

Hydraulic shisha charcoal machine

If you want to know the difference between this type of equipment and mechanical shisha charcoal maker, you need to understand the structure. So the main structure of the charcoal tablet press includes the frame, the motor, the hydraulic system, the PLC console, the mold, and the conveyor belt.

What binder can you use to make hookah charcoal briquettes?

Charcoal is a material totally lacking plasticity. Hence, you need addition of a sticking or agglomerating material to enable a briquette to be formed. Fun eyi, binder becomes a very important factor is the charcoal briquette making process. Ni afikun, pure charcoal is a thing which burns with no smoke, Ko si olfato. And the use of charcoal determines the type of binder it uses, Fun lilo iṣẹ oojọ, there would be wider choices in binders.

How much does hookah press machine cost?

Awọn price of shisha hookah charcoal making machine is an item you must pay attention to. But there is no doubt that you can buy shisha charcoal machine at a favourable price in YS. Because we are a source factory for charcoal briquettes making machine manufacturing, there is no extra charge during the transaction. Ni Gbogbogbo, the prices of the above hookah press machines are as follows:

$3,000-$4,300 Mechanical shisha charcoal making machine

Commonly, the price of charcoal briquettes making machine is related to the type. This type of machine use mechanical power to make biochar briquettes. So you need to prepare $3,000-$4,300 for purchasing this machine. And its capacity can get 1-6 t / h.

$6,500-$8,000 hydraulic hookah biochar machine

Do you want to finish charcoal briquettes making in a shorter time? Hydraulic hookah biochar machine can fully meet your needs. It makes use of hydraulic system to make biochar briquettes quickly. Nitori naa, it has a price of $6,500-$8,000.

Where can you buy a suitable hookah press machine?

Ys, as a professional charcoal briquettes making machine manufacturer, can provide you with customization service, after sales service and technical support.