Charcoal ball press machine is a roller-type briquette press that can compress charcoal powder into ball and pillow, etc shape briquettes. It is one of the key equipment in biochar briquettes production. Our company designs this machine with many years of experience in charcoal briquettes making. So the quality of roller press briquettes machine is guaranteed. And this machine can not only use mechanical force to make briquettes, ṣugbọn tun gba eto hdraulic iyọrisi ibi-iṣelọpọ Biochattetes. Fun eyi, more and more charcoal briquettes manufacturers prefer to use it to produce briquettes.

How does a charcoal ball press machine work in biochar briquettes making?

It is a simple process to manufacture biochar briquettes. Firstly you can feed raw materials into the hopper of the ball press machine. Then the screw propeller in the hopper rotates and pushes the raw material forward. During this process, two rollers make use of physical force to compress materials and the pressure gradually increases. Fun eyi, die holes of the ball press machine force out the compressed material in the form of briquettes or balls.

How to choose materials for briquettes making in charcoal ball press machine?

According to customer’s different requirements, a ṣe ọnà rẹ rola tẹ briquetting ẹrọ eyi ti o le gba orisirisi ohun elo ati ki o ni nitobi ti briquette.

Briquette ṣiṣe awọn iru ohun elo

Eedu briquettes awọn ohun elo igbaradi awọn ibeere

Here is an example:

In biochar briquette making process, when using lime and clay as binder, the moisture should be between 18-20%. but when you use pulp or sodium humate as binder, the moisture requirement change into 10-12%. So if the binder is asphalt, the moisture even low to 2-4%!

Why do you need to add binders before charcoal briquetting process?

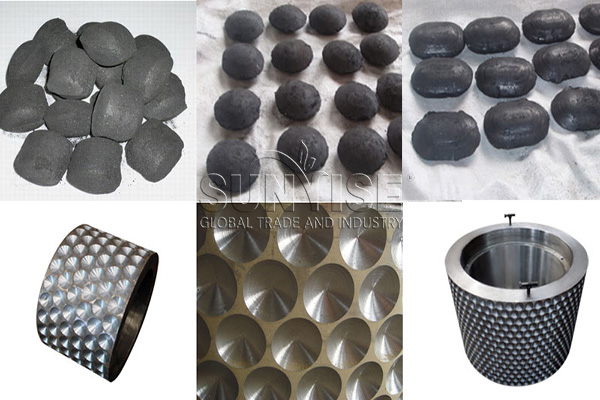

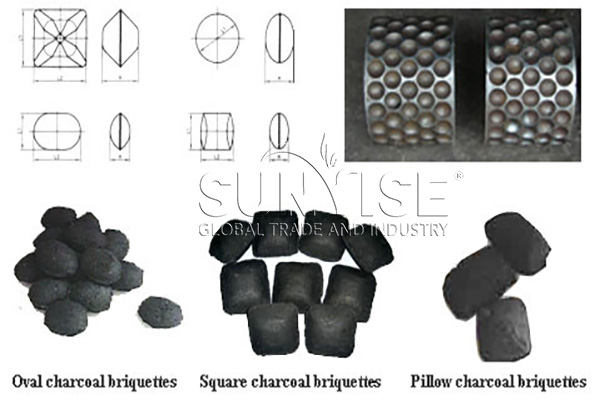

Final product of charcoal ball press machine

The shape of the biochar powder briquetting machine is determined by its mold. So we can provide customers with pillow, spherical, bread, and other molds. Jujun, we customize mold patterns and texts for customers. The following is the different shapes of final product image:

Elo ni rola tẹ briquetting ẹrọ iye owo?

L'akotan, idiyele ti ẹrọ titẹ bọọlu eedu jẹ ohun kan ti ọpọlọpọ awọn alabara ṣe akiyesi si. Ati pe o jẹ ifosiwewe pataki ni ṣiṣe ipinnu boya awọn alabara fẹ lati ra ẹrọ ṣiṣe awọn briquettes eedu yii.. Awọn owo ti yi ẹrọ lori oja jẹ nipa 3,500 dola / ṣeto si 58,000 dola / ṣeto sinu 2024, ati ki o yatọ pẹlu awọn oniwe-agbara ati iṣeto ni. Ti o ba fẹ mọ idiyele alaye ti ẹrọ titẹ bọọlu biochar o nilo, o le kan si wa.

Roller tẹ briquette ẹrọ ọgbin fun tita

O le lo ẹrọ titẹ bọọlu eedu nikan ki o darapọ pẹlu miiran itanna lati fẹlẹfẹlẹ kan ti eedu briquettes gbóògì ila. Feeder machine, iṣẹ didi, apopọ, belt conveyor and dryer, various combinations, you can choose as you need.