When you want to buy a high quality char-molder, a processional charcoal briquette machine manufacturer is necessary. In Sunrise, we can provide you with high quality biochar molding equipment. And we summarize the top 10 questions commonly inquired about Sunrise char molder manufacturer from our customers feedback as follows:

Q1: Are you a char-molder manufacturer and trade company?

We are a professional manufacturer for producing charcoal briquette making machine and related machine (carbonization furnace, grinder, mixer, packing, feeding machines and conveyor belt) etc.

Q2: How should to do if you meet some trouble while using?

We can provide you with the English manual book and video for showing how to resolve the problems. And if necessary, we will dispatch our engineer to your factory.

Q3: Do YS provide the installation service after ordering charcoal molding machines?

As for the single machine, we provide the users instruction and operation video. In addition, as for the production line, we provide the professional construction drawing, and arrange the engineer guide the user install the machines. Help the user train the skilled workers.

Q4: Can you visit our factory to see some charcoal molding plant with our machines?

We really give every customer a warm welcome to visit our factory, and we can take the customer to visit biochar briquette plants with our equipment.

Q5: What type of char-molder can Sunrise provide with?

In YS, there are four kinds of biochar briquette making machines for your choice. Charcoal rotary tablet press, charcoal extruder machine, charcoal ball press machine and hookah press machine.

Q6: How long can charcoal molding machine be used from Sunrise? How long is the shelf life of this machine?

Usually, as long as you follow our operation manual when using the machine, it can generally be used for 10 years. And we provide one-year warranty service, and after-sales service will be in place in time.

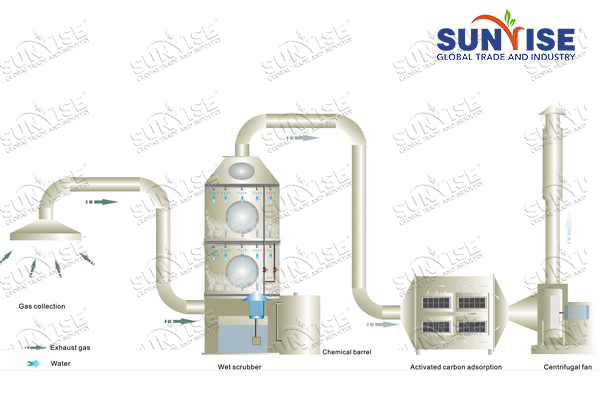

Q7: How to deal with dust generated during the charcoal briquette production process?

We have a complete dust removal system, including cyclone dust collector, air fan, bag filter dust collector and spray tower, etc. So you don’t have to worry about not meeting local environmental standards.

Q8: Does Sunrise has customization service when you buy char-molder?

Of course. Whether it is mold or equipment, we can produce it according to customer requirements. For example, add the company LOGO, adjust the color of the equipment, select the motor, etc.

Q9: How long does it take for Sunrise to deliver the goods after ordering charcoal molding machine?

Actually, it needs 15-20 days for making machines. But when we have some spot goods, we can delivery more quickly. You don’t have to worry about transportation, we will use steel wire to secure the equipment. And the shipments are differentiated according to the differences between single machines and production lines. Under normal circumstances, we ship a single machine directly as a whole, and the production line ships separately. Furthermore, we will test the equipment before shipping to ensure quality.

Q10: What after-sale service can Sunrise provide with customer?

After customer’s machine is put into operation, we will follow up and visit irregularly to understand the machine operation, production capacity, service condition of wearing parts and other problems encountered by the customer at this stage. So as to solve the problems immediately and give more technical guidance. Then we will sort out and analyse some cases from customer’s feedback, then report to the R&D Department to optimize and design, and apply the most advanced technology into production to provide better products for our customers.