Tanzania is suffering from the environmental burden of excessive logging due to its large charcoal briquette exports. In order to prevent continuous environmental degradation, local people use other materials instead of wood to produce charcoal briquette. But there is a concomitant that needs to focus on. How are charcoal briquettes made from other materials? Charcoal briquette making machine is necessary. So on 5th March 2024, a customer from Tanzania inquired about small scale charcoal briquette making machine from rice husk.

Why should you choose rice husk as material to make charcoal briquette?

This Tanzanian customer prepared to use rice husks with other other materials, such as sawdust, wood chips, coconut shells,etc to make biochar briquettes. Why?

Rice husk

It contains about 30-50% of organic carbon and has a high heat value of 13-16 MJ per kg. And rice husk is what is left collected after rice milling and has high moisture content. Mixing it with other materials to make biochar briquettes is the best choice for you.

Coconut shell

It is a permanent crop that grows in about 92 countries today. Then the coconut shell has a high calorific value and contains lower ash content than others, high volatile matter content and being a permanent crop. So it is available in abundant quantity at a cheap cost. In addition, the carbon content in coconut shell leads to the production of a superior quality residue which can be converted to activated carbon in waste water treatment along with the potential of replacing wood and other traditional fuel sources.

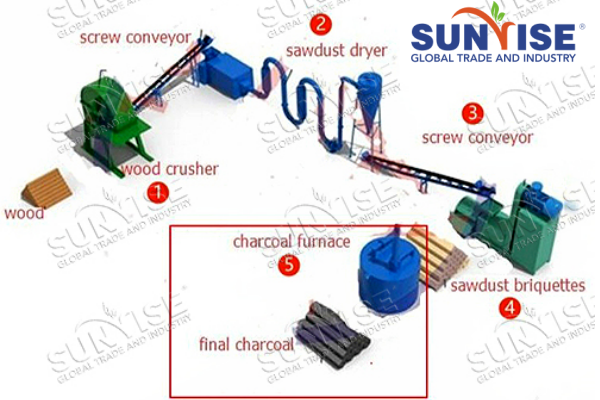

What machines are suitable for small scale biochar briquette production?

Because Tanzanian client wanted to produce small scale or medium scale charcoal briquette, what equipment is suitable for making them?

What is the cost of small scale rice husk biochar briquette making machine?

During small scale rice husk charcoal briquette plant setup, cost is an item you must focus on. According to your budget for charcoal briquette making, YS can offer you suitable solutions and equipment. Generally, the cost of biochar briquette manufacturing consists of equipment purchasing, area preparation, labor force and energy consumption.

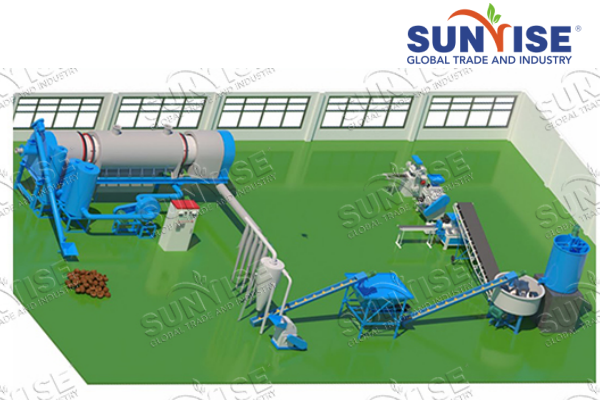

How much area do you need to prepare for small scale rice husk biochar briquette plant installation?

Provided you want to run small scale rice husk charcoal briquette manufacturing smoothly, you also need to prepare a suitable area for the production line installation. This Tanzanians client didn’t know how much space it will take. So how much area does it cover?

500-1000kg/h rice husk charcoal briquette plant

For 500kg/h-1000kg/h rice husk charcoal briquette manufacturing, you need to offer a 100-150㎡of area for it.

1-10 t/h rice husk biochar briquette making line

But when you want to setup a 1-10 t/h rice husk biochar briquette making line, it will need a workshop covering an area of 500-1000㎡.

Briefly discussion of the differences between large scale and small scale rice husk biochar briquette making

For different scale rice husk charcoal briquette production, as a businessman, you need to think about different aspects. Now let us discuss it in details for Tanzanians client’s requirements. Meanwhile, there are some tips can be offered in time.

Choosing professional manufacturer whether small scale and large scale rice husk charcoal briquette production. They will give you professional charcoal briquette machine project or solution. Why not choose Sunrise? Sunrise company can provide you with different models in charcoal briquette machine industry. For example, small scale rice husk biochar briquette production line, large scale rice husk charcoal briquette plant, different machine. Making you satisfied is our ultimate goal. So if you need these machines, please contact us immediately.

Why Sunrise can provide you economical small scale rice husk charcoal briquette machine?

The customer from Tanzania wanted to understand our factory, we introduce him for detailed information.

Source factory price

As a leading charcoal briquette equipment manufacturer in China, Sunrise has its own charcoal briquette machine manufacturing factory, which is about 40,000㎡. So you can buy small scale rice husk charcoal briquette making machines at a source factory price. There is no extra charge, so it must be the most favorable price.

Customized project design

In addition, Sunrise will offer you small scale rice husk biochar briquette making plan according to your actual conditions. Of course, it contains your budget for small scale biochar briquette production. Therefore, contact us immediately to get your small scale preparation line!