In Saudi Arabia, hookah charcoal briquette is highly popular and widely used for enjoying the traditional shisha experience. To meet the growing demand, efficient and reliable hookah charcoal briquette production is essential. For this, as a professional char-molder manufacturer, YS can provide you with suitable hookah biochar briquette making projects. And we have had many successful cases. For example, on 1st March 2024, a customer from Saudi Arabia inquired about hookah charcoal molding. The following are the specific information in this case:

What is the layout of the hookah charcoal briquette production line?

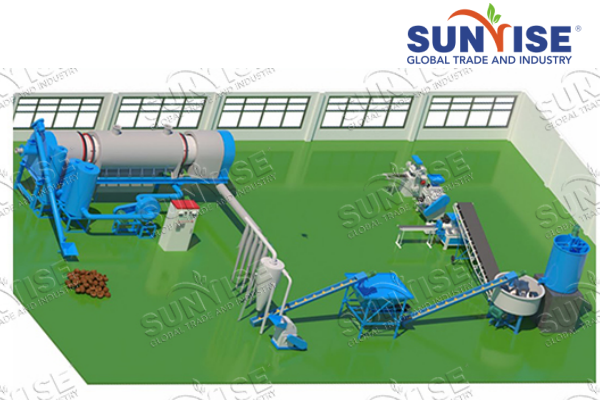

The customer from Saudi Arabia wanted to know the layout of shisha biochar briquette making line. But here, you need to decide what kind of charcoal molding methods you plan to use? Form first and then carbonize? Or carbonized first and then formed? The biochar briquette equipment used in these two hookah charcoal briquette making projects is different.

Form first and then carbonize

When you want to form briquette and then carbonize it, you need to buy several machines. They are crusher, mixer, dryer, briquette making machine, carbonization furnace, packaging equipment and belt conveyor.

Carbonized first and then formed

But if you plan to carbonize first and then form briquettes, you just need to adjust the order of the hookah charcoal briquette making machine. Such as carbonization machine, crusher, mixer, char-molder, dryer, packaging machine and belt conveyor. You can also choose suitable machines according to your needs.

How much area does hookah charcoal briquette manufacturing cover?

Then this Saudi Arabian customer also wanted to know the area occupation of the system for making shisha hookah biochar briquettes. Moreover, can it be accommodated by his workshop? In general, beside the layout, the area occupation of hookah charcoal briquette making is also closely related to the capacity. What is the capacity of this Saudi Arabian client’s shisha biochar briquette making plan? He told us that 500-1000 kg/h – with possibility to upgrade to 2 tons per hour in future. Usually, you need to prepare an area of 800-2,000㎡ for a 500-1000 kg/h hookah charcoal briquette making line.

How to turn materials into hookah biochar briquette in a small area?

You can consider it in two respects. On the one hand, choosing hookah charcoal briquette machines with less space occupation. Such as hookah press machine, hoisting carbonization furnace. On the other hand, designing shisha biochar briquette making line layout according to your actual conditions. Telling us more details of your workshop area, we will provide you with the best project design.

How much does hookah charcoal briquette making cost?

Finally, the customer from Saudi Arabia wanted to know the quote of the hookah charcoal briquette making line. The price is not fixed, because it is related to many factors. Capacity, design, equipment type, etc. However, the quote of a complete 500-1000 kg/h shisha biochar briquette production system is $100,000-$300,000. Is it high? No, all YS hookah charcoal briquette machines are made of high quality alloy, which is high wear-resistant and erosion-resistant.

Can we start hookah charcoal briquette manufacturing at a lower cost?

Of course. For one thing, you can replace drying equipment with natural drying, which can save more cost. For another, you can choose charcoal extruder briquette line to make shisha charcoal. This machine is economical, so you can save the money in the process of making hookah biochar briquette. Don’t worry, we will offer you project design according to your budget.