How to make BBQ biochar briquette? For many people who want to try to produce BBQ charcoal briquette, this is the first question before them. With the popularity of barbecue all over the world, the market demand for BBQ charcoal briquette has also increased. And the business of producing BBQ biochar briquette has gradually attracted the attention of investors. So on 15th January 2024, a customer from Turkey inquired about it. Finally, according to his requirements, we recommend him charcoal ball briquette making machine. And the customer gave us a good feedback.

What raw materials can make BBQ charcoal briquette?

This customer from Turkey is a new barbecue charcoal briquette manufacturer. And he still doesn’t know what raw materials are suitable for making barbecue charcoal. So he wanted us to give some advice.

Wood is the most common raw material for producing BBQ charcoal briquette, including hardwood, miscellaneous wood, fruit wood, etc. These woods can be used to produce natural charcoal briquette without any additions. So most of them retain the shape of the logs themselves, are easy to ignite, and emit a natural firewood smell when grilling.

The common ones are black olives, walnuts, olives, date pits, and coconut shells. And the charcoal briquette made from these raw materials can emit the unique fragrance of the raw materials when burning them.

Wood scrap, such as sawdust, shavings, bamboo chips, rice husks, etc. And these raw materials are mostly used for the production of machine-made charcoal briquettes.

Natural charcoal VS BBQ charcoal briquettes

Then Turkish client wanted to know why do you need to make BBQ charcoal briquette or not natural BBQ charcoal. There are three reasons as follows:

What is the process of making BBQ biochar briquette?

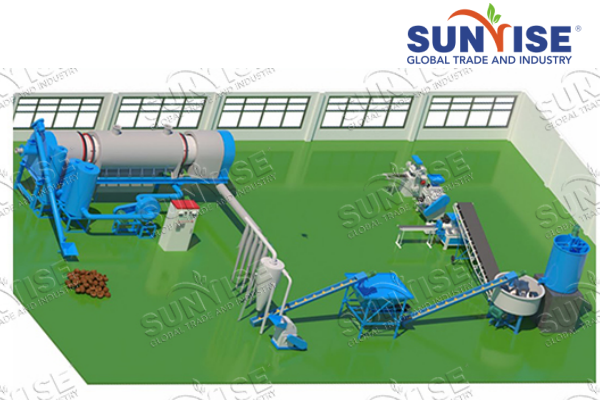

Finally, after understanding the above details, this Turkish customer asked us how to produce barbecue charcoal briquettes. It can be divided into two parts:

Production process of BBQ charcoal

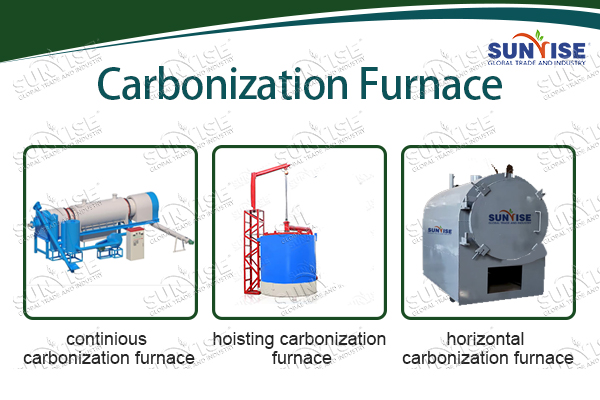

As mentioned above, there is only one process in the production of BBQ charcoal, which is carbonization. Regarding natural BBQ charcoal production, there are two points that need to be mentioned. One is that the moisture content of raw materials should not be too high, it is best to keep it below 30%, the drier the better. Because the drier the raw material, the shorter the time required for dehumidification during the carbonization process, and the less fuel consumption. The other is that properly prolonging the carbonization time and temperature can effectively improve the quality of BBQ charcoal. There are three types carbonization furnaces for your choice. Such as hoisting, horizontal and continuous carbonization machine.

Manufacturing BBQ biochar briquette

After carbonizing materials, you can crush them into biochar powder. Then mixing powder with water and binder. It can effectively improve the quality of BBQ charcoal briquettes. Finishing the above steps, you can use charcoal ball press machine to make BBQ biochar briquette. In addition, in order to transport and store conveniently, packaging is necessary.