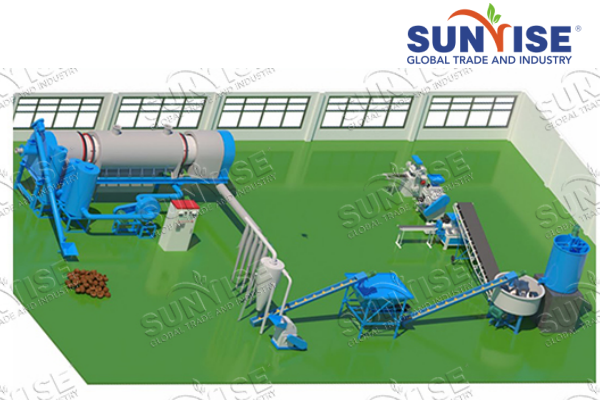

In Malaysia, coconut shell is the fourth important industrial crop after oil palm, rubber and paddy in terms of total planted area and it is an important export country of coconut products. Due to its high carbon content and hardness, coconut shells are an excellent raw material source to produce biochar briquettes. On 2nd March 2024, a Malaysian client inquired about how to start coconut shell biochar briquettes making? According to his requirements, we sent a 3-4 t/h coconut shell charcoal molding system.

How to start large scale coconut shell biochar briquette making?

This customer told us that for a project in Malaysia, he needs a coconut shell charcoal briquette production line for briquetting and the expectant capacity is 3-4 t/h. Which charcoal briquette making machine is suitable for this? Both charcoal extruder machine and charcoal ball press equipment are idea choices for you.

Charcoal ball press machine for easier large scale coconut biochar molding

According to the requirements of this Indian client for 3-4 t/h production of coconut charcoal briquette, we recommended him charcoal ball press machine. Because only need a charcoal ball briquette machine, you can finish this large scale coconut biochar briquette manufacturing plan. You can buy YS-290, which can produce 3-4 tons of coconut biochar briquette per hour for you. In addition, whether you want to prepare high, medium or low concentration charcoal briquette, it can fully meet your needs. Because the equipment material is Q245 R steel+S310 stainless steel, which has high performance in erosion resistance.

Rod biochar extruder for processing coconut charcoal briquette effectively

When we talked about the briquetting rate of charcoal ball press is about 90%. This Indian customer asked us that is there charcoal briquette equipment with a higher briquetting rate? Of course. It is advisable to choose our rod biochar extruder, whose briquetting rate can reach 99%. That is, with the same amount of coconut charcoal powder, the biochar extruder machine can produce more briquettes. And there is less powder that needs to be returned to re-briquette. Then because the largest output of this equipment is 10 t/h. For 3-4 t/h coconut biochar molding, you only need to use YS-210 rod charcoal extruder.

What is the voltage of the coconut biochar molding equipment?

When you buy equipment for coconut biochar briquette manufacturing, it is also essential to focus on the voltage. After understanding the basic information of coconut shell charcoal briquette equipment. This Indian customer paid attention to the voltage. What is the voltage of charcoal ball briquette making machine and rod biochar extruder? Can it suitable for 220v / 380v / 415v / 440v / 480v (50Hz/60Hz)? As a reliable char-molder manufacturer, we can change the voltage of biochar briquette machines according to your requirements. So whether you need char-molder equipment with any voltage, you can contact us for voltage adjustment. Of course, including 220v / 380v / 415v / 440v / 480v (50Hz/60Hz).

How to dry coconut shell biochar briquette moisture to 10%?

Generally, you need to prepare $50,000 – $300,000 for the above 3 t/h charcoal extruder briquette plant. However, if you want to finish sawdust charcoal briquette making at a lower cost, we can also meet your requirements.

Finally, the client from India also planned to purchase a dryer for coconut biochar briquette. Because this customer wanted to prepare briquette that have a 5%-10% moisture. But, after briquetting, it is usually about 20%-30%. For this, we recommend you choose our mesh belt drying equipment. With the transportation of conveyor belt, it can dry your coconut shell charcoal briquette evenly and quickly. In addition, because of its fully enclosed drying environment, it can further shorten the drying time. Then for 3-4 t/h charcoal briquette drying, it is advisable to choose our YSWD – 1.2-8 mesh belt dryer.