In the recent past, the presence of natural charcoal is diminishing. But its demand has been high while the supply is limited. Partly because of diminished forests and the desire to conserve the trees. As a result, charcoal briquette making machine is becoming popular today. And starting a charcoal briquette business has been profitable project in many countries, like South Africa, Uganda, Kenya, etc.. For this, on 19th April 2024, we received a charcoal briquette making customer from Kenya. This client wanted to make charcoal briquette from sawdust. But he didn’t know what the production process is. The following are the detailed information in this case:

Why Is Sawdust Charcoal Briquette Making Popular in Kenya?

Kenya has long relied on traditional wood charcoal for cooking and heating, but with increasing deforestation and the rising cost of fuel, the search for alternative energy sources has become urgent. In recent years, producing charcoal briquettes from sawdust has gained popularity across the country. This eco-friendly solution not only reduces waste but also provides a sustainable source of income and energy for local communities.

Kenya’s furniture and timber industries generate large amounts of sawdust every day, most of which used to be burned or dumped. By converting this waste into charcoal briquettes, manufacturers can turn low-value residues into high-value fuel. This process helps reduce environmental pollution and promotes circular economy practices.

The Kenyan government encourages renewable energy initiatives and sustainable waste management. Projects that convert agricultural and wood waste into briquettes align with national clean energy goals and often receive support from NGOs and local authorities. This favorable policy environment makes sawdust charcoal production even more attractive to entrepreneurs.

With urban populations expanding and traditional charcoal prices increasing, demand for cheaper and cleaner fuel is growing rapidly. Sawdust charcoal briquettes burn longer, produce less smoke, and are more affordable for households, restaurants, and small industries-making them an ideal alternative in both rural and urban markets.

What Kind of Sawdust Is Used for Making Briquettes in Kenya?

Quality Requirements for Sawdust

The quality of sawdust has a direct impact on the strength, burning efficiency, and appearance of briquettes. Clean and uniform sawdust leads to higher carbonization efficiency and better compression during molding. The raw material should be free from paint, varnish, or chemical residues, as these can produce toxic gases during combustion. Finer particles are preferred because they fill molds evenly and bind more tightly under pressure. Choosing pure, uncontaminated sawdust ensures that the final briquettes are safe, odorless, and environmentally friendly.

How to Control the Moisture Content of Sawdust

Moisture control is one of the most critical factors in briquette production. The ideal moisture content of sawdust is between 8% and 12%. If the material is too wet, the briquettes will not hold their shape and will take longer to dry after pressing. On the other hand, overly dry sawdust lacks flexibility and reduces the bonding strength between particles.

To achieve the right balance, producers often dry sawdust under the sun or use a rotary drum dryer for faster and more consistent results. During rainy seasons, storing sawdust under a covered shed and using airflow dryers helps prevent moisture absorption. Regularly checking the material’s moisture level before carbonization or briquetting ensures stable production and high-quality briquettes.

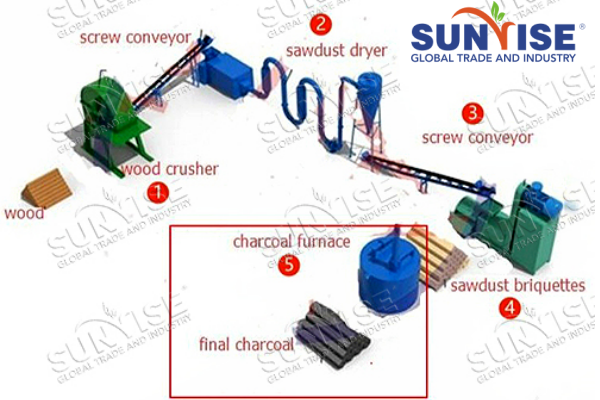

What is the Process of Making Biochar Briquette from Sawdust?

This Kenyans customer wanted to know the process of producing sawdust biochar briquette. In general, there are 4 steps in the production of sawdust charcoal briquette.

What is the Advantage of Making Sawdust Charcoal Briquette?

Finally, customer from Kenya prepared to make sawdust charcoal briquette for a lone time. But he was worried that the profit would not be as good as selling natural sawdust charcoal. We explained to him the advantages of processing sawdust charcoal briquette.

How Much Does a Small&Large Scale Sawdust Charcoal Briquette Plant Cost?

The capacity plays an important role in sawdust charcoal briquette plant cost. The price of sawdust biochar briquette machines will increase with the capacity. This Kenya customer wanted us to give him a price plan.

How Much Does It Cost to Start a Sawdust Charcoal Briquette Business in Kenya?

Starting a charcoal briquette business in Kenya is one of the most promising clean energy investments today. With abundant sawdust from furniture and wood industries, and growing demand for eco-friendly fuels, our customer is turning this waste into profit. However, before launching your briquette project, it’s crucial to understand the initial investment, machine cost, and expected returns.

What Are the Main Costs of Setting Up a Sawdust Charcoal Briquette Factory?

Establishing a sawdust charcoal briquette production line involves expenses for equipment, installation, site preparation, labor, and electricity. The cost largely depends on your desired production capacity and automation level.

| Cost Category | Description | Estimated Cost Range |

| Installation & Commissioning | Machinery setup, test running and technician guidance | $2,000-$10,000 |

| Site Preparation | Factory building, foundation work, ventilation and layout design | $5,000-$30,000 |

| Labor Cost | Operators, technicians and management staff salaries | $2,000-$10,000/month |

| Electricity & Fuel | Power consumption for machines and heat source for drying and carbonization | $1,000-$5,000/month |

| Raw Materials | Sawdust, wood shavings, rice husk or other biomass feedstock | $500-$3,000/month |

| Transportation | Shipping of equipment and raw materials | $1,000-$8,000 |

| Maintenance & Spare Parts | Replacement parts, regular machine maintenance and lubricant | $1,000-$3,000/year |

| Miscellaneous | Licenses, taxes, safety equipment, office supplies, etc | $1,000-$5,000 |

What Factors Influence the Total Investment of Sawdust Charcoal Briquette Production?

Several factors affect your total startup cost beyond the machines themselves.

Top 3 Carbonization Machines for Sawdust Charcoal Briquettes Making

After discussing the process, the Kenyan customer wanted to know which carbonization furnace is the most suitable for producing sawdust charcoal.

Hoisting carbonization machine

The hoisting carbonization furnace includes an electric hoist. With the electric hoist, it can lift the inner tank easily, which save labor cost. And each furnace is equipped with 3 inner tanks. Its carbonizing time is 8-12 hours to ensure the good quality of charcoal. After one tank of materials finishes carbonization, you can lift out it by the hoist and then put another tank of materials for charring.

Horizontal carbonization furnace

Horizontal carbonization machine adopts a horizontal design to reduce machine height. So it is more convenient for loading raw materials. And it also includes a smoke recycle system. Smoke generated in the carbonizing process enters the purifier and then be ignited for heating the furnace. What’s more, it produces charcoal by batch, carbonizing time 8-10 hours, water cooling time 2-3 hours, air cooling 6-8 hours.

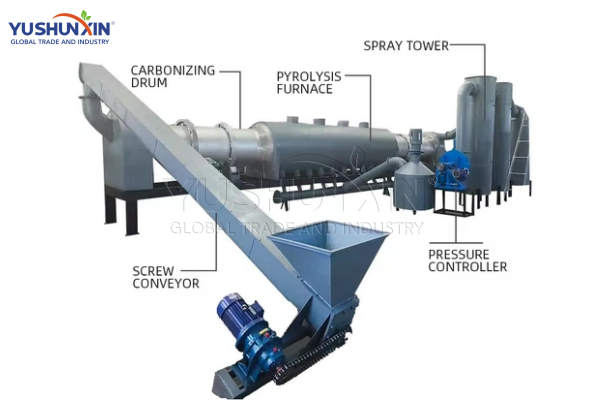

Continuous carbonization equipment

Continuous carbonization furnace is suitable for charring the biomass materials which are in small pieces. When you use this machine for producing charcoal, we suggest the size of materials not bigger than 50mm. Though the carbonization rotary kiln has the function of drying, we don’t suggest carbonizing the wet materials directly, it will affect the carbonizing efficiency and charcoal quality. So it is better that make sure the moisture of materials is less than 30%.

Testing Report of Sawdust Biochar Briquette Made from Charcoal Molding Machine

Here we select local Chinese sawdust to test the quality of sawdust charcoal briquette. The report indicates that the calorific value of the sawdust charcoal briquette produced by our sawdust charcoal briquette machine has exceeded 6000 kcal/kg, approximately doubling that of raw sawdust (typically 3000-4500 kcal/kg). This outstanding performance makes sawdust charcoal briquette a reliable and efficient energy source with good economic benefits. Therefore, we sincerely recommend that customer consider this project.

|

Kind |

Sawdust |

|---|---|

| Total Moisture Mt% |

6.84 |

| Analytical Water Mad% |

4.51 |

| Dry Basis Ash Ad% |

5.871 |

| Volatile Matter on Dry Basis Vd% |

20.8 |

| Fixed Carbon Fcad% |

68.91 |

| Sulfur Content on Dry Basis St.d% |

0.08 |

| New national standard calorimeter dry basis high calorific value kcal/kg |

6454 |

| The new national standard calorimeter method receives the base low calorific value kcal/kg |

6088 |

Note: Different types, moisture, sizes of raw materials, and technical parameters will have an impact on the biomass carbonization results.

Feasibility and ROI of Investment in Sawdust Charcoal Briquette Project

Several key factors contribute to the promising profit prospects of investing in a sawdust charcoal production project. Now, let’s delve into this investment for Kenya customer.

The above are details about how to make charcoal briquette from sawdust in Kenya. Besides, we can also offer you other charcoal briquette production lines. Such as 3 t/h sawdust charcoal briquette machine, BBQ biochar briquette making plant and bamboo charcoal briquette plant, etc.